wacky1980

Active Member

lol long shanks. like the guy in the movie... anyways

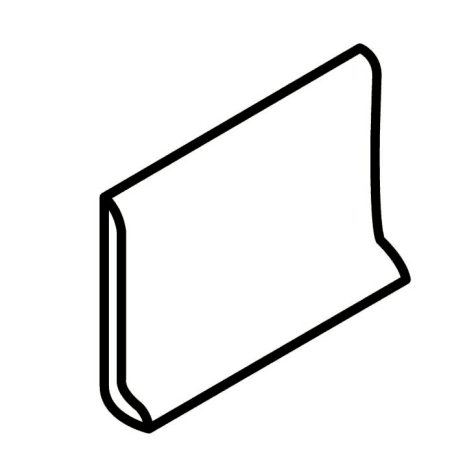

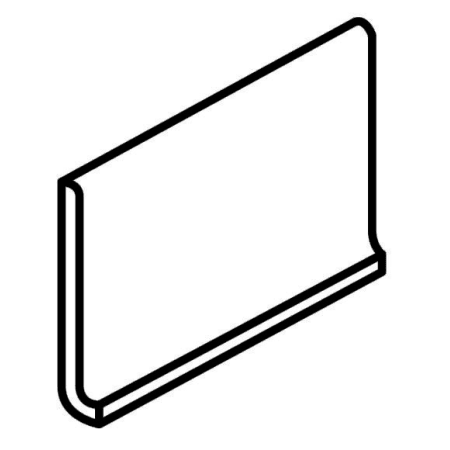

i'm building an outdoor venue this spring, and i'm throwing together a walk-in cooler with an 8-tap setup from scratch. i plan on walls being built with 2x4 studs turned sideways, plus 4" of polyiso foam inside that for proper R-value. that's ~6" of wall depth i'll need to bore through in order to get from inside the cooler, out to the faucet. this means a lot of pours are going to start warm, which is obviously a no-no. i don't want the first spurt off each pour to be a blob of foam that just compounds inside the glass. that's a lot of waste.

so i'm trying to weigh my options here. if i were to simply cut out a 6" wide by 3" deep trench in the foamboard to shorten up the wall thickness around the tap shanks to 3" (1" insulation and 2" dead space inside framed wall), would the cooling area on the shank be close enough to the faucet to avoid having foam issues? and would i be screwing my overall R-value in the process? would it help to fill the wall with foam between the studs, or would that just be a waste of time/money?

i'm not interested in active cooling systems like glycol right now because i'm trying to keep costs down as much as possible. with that in mind, is there a better way to keep the beer at the faucet at or near serving temp, that i've not already thought of?

i'm building an outdoor venue this spring, and i'm throwing together a walk-in cooler with an 8-tap setup from scratch. i plan on walls being built with 2x4 studs turned sideways, plus 4" of polyiso foam inside that for proper R-value. that's ~6" of wall depth i'll need to bore through in order to get from inside the cooler, out to the faucet. this means a lot of pours are going to start warm, which is obviously a no-no. i don't want the first spurt off each pour to be a blob of foam that just compounds inside the glass. that's a lot of waste.

so i'm trying to weigh my options here. if i were to simply cut out a 6" wide by 3" deep trench in the foamboard to shorten up the wall thickness around the tap shanks to 3" (1" insulation and 2" dead space inside framed wall), would the cooling area on the shank be close enough to the faucet to avoid having foam issues? and would i be screwing my overall R-value in the process? would it help to fill the wall with foam between the studs, or would that just be a waste of time/money?

i'm not interested in active cooling systems like glycol right now because i'm trying to keep costs down as much as possible. with that in mind, is there a better way to keep the beer at the faucet at or near serving temp, that i've not already thought of?