ebstauffer

Well-Known Member

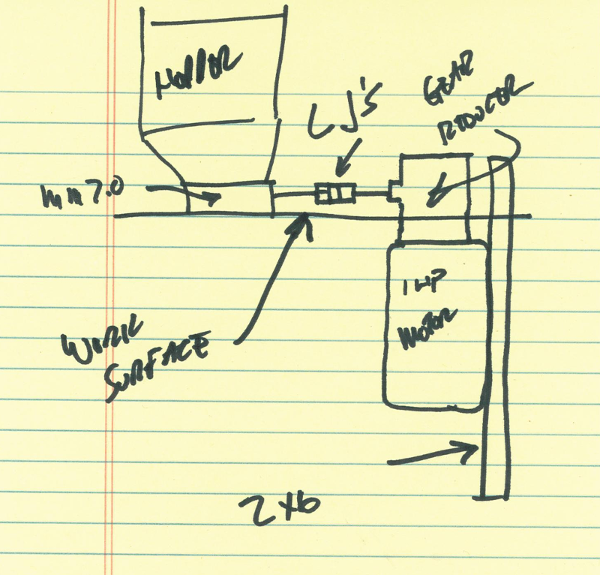

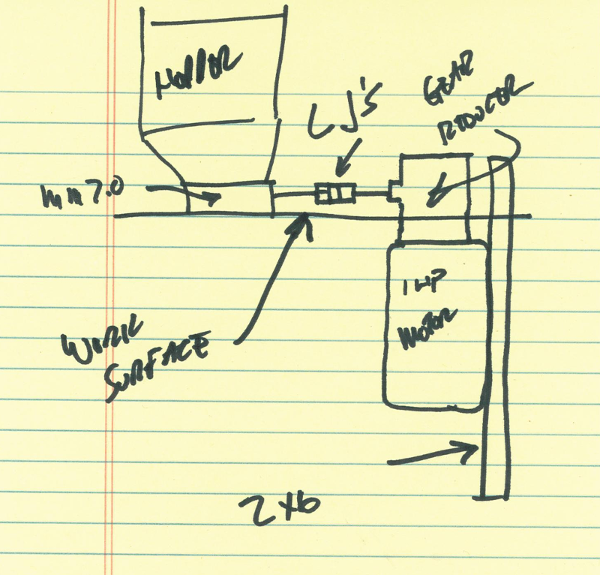

In a nod to drunkenmonk's build, I too have set off on this budget-busting build. One small change I'd like to make is to mount the beastly motor vertically beneath the work surface. Something like the attached. Is there any reason why I shouldn't orient the motor vertically other than mounting will be a b*tch as it weighs 58 lbs?

Eric

Eric