Normally when want to age something for a long time I use a secondary but I have a barely wine that will take a very long time so I was considering using a keg. I've read that many people use kegs instead of secondaries so I know it can be done. Are there any special steps to take when doing this? I assume after racking to the keg you bleed out the o2 with a bit of co2 or is that not necessary? Also I usually have an airlock on my secondaries, is that needed for a keg? Or is it ok if it gets mildly carbonated naturally? Or should I fully carbonate the keg and then just set it aside to age?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Using keg as long term secondary - co2 and airlock

- Thread starter pretzelb

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

milldoggy

Well-Known Member

I have done it two ways, seal it up, bleed o2 and charge with co2. One risk you run is over carbing if a secondary ferm does occur. The other way it to remove the gas disconnect and post and put a stopper over it and an airlock. I just screwed on a stopper, made a tight seal. There are special lids you can order too

milldoggy

Well-Known Member

Should have asked, corny keg or Sankey?

milldoggy

Well-Known Member

- Joined

- Jan 14, 2015

- Messages

- 1,101

- Reaction score

- 316

You know, I actually have those same lids, and was wondering about using them.

If I fill the keg, add a normal lid, purge with CO2, and then swap the lids, doesn't that just let O2 back in again?

If I fill the keg, add this lid, and then purge with CO2, won't it just all shoot out the airlock, thus not being a very effective purge?

Anything wrong with using a regular lid and just pulling on the PRV every couple of days to let out any excess CO2 that builds up?

If you went that route, what PSI would you recommend setting the keg to at the initial fill?

If I fill the keg, add a normal lid, purge with CO2, and then swap the lids, doesn't that just let O2 back in again?

If I fill the keg, add this lid, and then purge with CO2, won't it just all shoot out the airlock, thus not being a very effective purge?

Anything wrong with using a regular lid and just pulling on the PRV every couple of days to let out any excess CO2 that builds up?

If you went that route, what PSI would you recommend setting the keg to at the initial fill?

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

MagicMatt

Brewmathemagician

You don't need to worry about the pressure when you use the keg as secondary. Purge the keg with CO2 and then let it pressurize to about 30 psi and disconnect the gas. There's very minimal chance of overcarbing, as the pressure would have to remain at 30 psi for over a week to reach the desired pressure, let alone get over carbed. Most of that 30 psi initial charge will be absorbed by the beer during carbonation.

Even if the beer is still putting off CO2, it will start to absorb it from the headspace as well until all is equalized. This has a near zero chance of happening from secondary fermentation alone.

Either way I would recommend getting a pressure tester like this one: http://www.williamsbrewing.com/KEG-PRESSURE-TESTER-P715.aspx

One of the best pieces of equipment I've purchased for my kegs. Just check the pressure every few days and if it gets above the carb level for the volumes of CO2 you want, purge it until it gets to the correct psi.

Even if the beer is still putting off CO2, it will start to absorb it from the headspace as well until all is equalized. This has a near zero chance of happening from secondary fermentation alone.

Either way I would recommend getting a pressure tester like this one: http://www.williamsbrewing.com/KEG-PRESSURE-TESTER-P715.aspx

One of the best pieces of equipment I've purchased for my kegs. Just check the pressure every few days and if it gets above the carb level for the volumes of CO2 you want, purge it until it gets to the correct psi.

I'd keg it and carb it up once it's at FG.

What is there to be gained by not carbing it up. The beer can age equally as well this way. Assuming the keg does not have a leak there is no downside.

No airlocks or iffy seal to worry about.

Keg it, carb it up, age it wherever you want at whatever temperature you want.

If you really are worried about the beer continuing to ferment (not sure why you would be) you could place a spunding valve on the keg and set it to the desired psi. Non-problem solved.

What is there to be gained by not carbing it up. The beer can age equally as well this way. Assuming the keg does not have a leak there is no downside.

No airlocks or iffy seal to worry about.

Keg it, carb it up, age it wherever you want at whatever temperature you want.

If you really are worried about the beer continuing to ferment (not sure why you would be) you could place a spunding valve on the keg and set it to the desired psi. Non-problem solved.

- Joined

- Jan 14, 2015

- Messages

- 1,101

- Reaction score

- 316

So it sounds like some sane advice would be...

- Fill the keg as normal

- Pressurize keg to about 30 PSI

- Forget about it

- Don't worry about putting a specialized lid or airlock on it

- If you can't help but worry about it, check the pressure every once in a while*

* The pressure should drop from 30 PSI while the beer absorbs some CO2 and things equalize out, correct?

Is that a reasonable way to look at secondary in a keg?

- Fill the keg as normal

- Pressurize keg to about 30 PSI

- Forget about it

- Don't worry about putting a specialized lid or airlock on it

- If you can't help but worry about it, check the pressure every once in a while*

* The pressure should drop from 30 PSI while the beer absorbs some CO2 and things equalize out, correct?

Is that a reasonable way to look at secondary in a keg?

If you have no plans to move it out of this first receiving keg into another then it is not a secondary vessel.

It's just a keg of beer. Carb the sucker up. Why wait.

If you plan on racking the beer from this secondary vessel keg to another you would be correct in describing it as a secondary vessel.

Then you can make a good case for not carbonating the beer right away. You don't need an airlock though. Gas QD and some line into starsan is all you need (or a spunding valve to allow a slightly pressurized secondary)

This is not just semantics, moving fully carbonated beer from keg to keg poses a different set of easily solvable issues than moving uncarbonated beer.

It's just a keg of beer. Carb the sucker up. Why wait.

If you plan on racking the beer from this secondary vessel keg to another you would be correct in describing it as a secondary vessel.

Then you can make a good case for not carbonating the beer right away. You don't need an airlock though. Gas QD and some line into starsan is all you need (or a spunding valve to allow a slightly pressurized secondary)

This is not just semantics, moving fully carbonated beer from keg to keg poses a different set of easily solvable issues than moving uncarbonated beer.

*ignorantly scrolls to the bottom, disregarding any previou helpful posts*

There really shouldnt be much of any CO2 being released in the secondary. Even if some did, its not gonna be enough to overcarb your beer or be dangerous. As long as its done fermenting before you transfer it, just purge it a few times and leave it pressurized to seal the lid

There really shouldnt be much of any CO2 being released in the secondary. Even if some did, its not gonna be enough to overcarb your beer or be dangerous. As long as its done fermenting before you transfer it, just purge it a few times and leave it pressurized to seal the lid

I'd keg it and carb it up once it's at FG.

What is there to be gained by not carbing it up. The beer can age equally as well this way. Assuming the keg does not have a leak there is no downside.

No airlocks or iffy seal to worry about.

Keg it, carb it up, age it wherever you want at whatever temperature you want.

If you really are worried about the beer continuing to ferment (not sure why you would be) you could place a spunding valve on the keg and set it to the desired psi. Non-problem solved.

The thing on the bottom of the "wye" is an adjustable pressure relief valve, like this one: http://www.amazon.com/gp/product/B007GDY3CU/?tag=skimlinks_replacement-20

Brew on

Last edited by a moderator:

Deleted

pretzelb

Well-Known Member

What is there to be gained by not carbing it up. The beer can age equally as well this way. Assuming the keg does not have a leak there is no downside.

I wasn't sure so I asked. Normally a secondary has no carbonation of course so I was wondering if that was for a reason or not. Obviously you can bottle age and that requires carbonation, but I wasn't sure if there was a time/place/reason to do one or the other.

I like the idea of not having the airlock since that would cut down on the height requirements. I could fit it easily in my fermentation keezer. Plus if I used the pressurized keg it would be easy to collect samples.

Only drawback I can see is possible sediment but that should run off after a pint or two.

I might pick up one of those pressure gauges.

- Joined

- Jan 14, 2015

- Messages

- 1,101

- Reaction score

- 316

So would it make sense to say...

If you are doing a true secondary fermentation (adding fruit, souring bugs, or something along those lines where you expect some sort of reaction to happen in the vessel and/or will transfer it from said vessel at some point in the future) then you should not pressurize in the keg and probably want to use some sort of airlock or pressure release.

But, if you are really more bulk conditioning (not expecting any sort of reaction and not planning to transfer from the vessel at a later date) then just go ahead and pressurize the keg and carb it up before letting it sit?

For example, I like to add souring bugs to some beers after primary fermentation is complete, so for those I would do a secondary in the keg, but not pressurize/carbonate.

On the other hand I am also planning on brewing a big barleywine in the near future, that I planned to bulk condition for 6 months or so, and for that one I will just transfer to a keg after primary, carb it up, and then let it sit.

If you are doing a true secondary fermentation (adding fruit, souring bugs, or something along those lines where you expect some sort of reaction to happen in the vessel and/or will transfer it from said vessel at some point in the future) then you should not pressurize in the keg and probably want to use some sort of airlock or pressure release.

But, if you are really more bulk conditioning (not expecting any sort of reaction and not planning to transfer from the vessel at a later date) then just go ahead and pressurize the keg and carb it up before letting it sit?

For example, I like to add souring bugs to some beers after primary fermentation is complete, so for those I would do a secondary in the keg, but not pressurize/carbonate.

On the other hand I am also planning on brewing a big barleywine in the near future, that I planned to bulk condition for 6 months or so, and for that one I will just transfer to a keg after primary, carb it up, and then let it sit.

I wasn't sure so I asked.

I might pick up one of those pressure gauges.

Sorry. I didn't mean to come across as a snarky bollox. Truly not my intent.

I wouldn't bother with the spunding valve unless you're planning on finalizing the fermentation in the keg and allowing this to carbonate the beer naturally for you. Mimicking a commercial bright tank so to speak.

Were you restricted by a self imposed homebrewing reinheitsgebot or wanted to save on CO2 this would be a good idea. Downside is greater sediment in the keg.

Some home brewers ferment in a keg and will use one in this manner. Typically the out dip tube is shortened to remain above the anticipated trub line and the beer is subsequently racked to a serving keg in a closed pressurized setup following FG being reached.

Otherwise I can't really see the need.

I like to secondary / bulk condition my brews, especially dark / big beers. I also will add sugar to let the brew carbonate itself, This has worked very well. My storage area maintains a temperature of about 35 to 50 degrees. After a period of time, I will hit each keg with a blast of CO2 at about 15 psi. When I can close to tapping my keg, I will place it in my kezzer and attach the gas. Has worked well. Good Luck

You need to do more than "bleed out the o2 with a bit of co2." Commercial breweries shoot for less than 0.2 ppm or 200 ppb (parts per billion) TPO (Total Packaged Oxygen) to minimize staling from oxidation (ref: page 21 of http://www.craftbrewersconference.com/wp-content/uploads/2015_presentations/F1540_Darron_Welch.pdf.) The longer you age, the more important controlling TPO is, unless you are looking for some oxidation flavors like sherry notes (which might be ok in a barley wine, I'm not an expert on those.)Normally when want to age something for a long time I use a secondary but I have a barely wine that will take a very long time so I was considering using a keg. I've read that many people use kegs instead of secondaries so I know it can be done. Are there any special steps to take when doing this? I assume after racking to the keg you bleed out the o2 with a bit of co2 or is that not necessary? Also I usually have an airlock on my secondaries, is that needed for a keg? Or is it ok if it gets mildly carbonated naturally? Or should I fully carbonate the keg and then just set it aside to age?

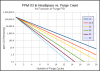

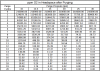

TPO is calculated as:

(Headspace Vol * Headspace O2 + Beer Vol * Beer O2) / Package Vol

Package Vol = Beer Vol + Headspace Vol

If you fill the keg by siphoning thru the open lid, then it takes multiple pressurize and vent cycles to get the O2 down to ppm or ppb levels. The chart and table below show how much O2 is left in ppm for different numbers of purge cycles at different pressures.Package Vol = Beer Vol + Headspace Vol

You can get lower O2 levels with less CO2 usage by filling the keg completely with water or StarSan, pushing the liquid out with CO2, and then filling the keg thru the liquid out post (need to open the PRV to allow filling.)

Each brewer needs to decide for them self how OCD they want to be about minimizing TPO.

Brew on

So would it make sense to say...

If you are doing a true secondary fermentation (adding fruit, souring bugs, or something along those lines where you expect some sort of reaction to happen in the vessel and/or will transfer it from said vessel at some point in the future) then you should not pressurize in the keg and probably want to use some sort of airlock or pressure release.

But, if you are really more bulk conditioning (not expecting any sort of reaction and not planning to transfer from the vessel at a later date) then just go ahead and pressurize the keg and carb it up before letting it sit?

For example, I like to add souring bugs to some beers after primary fermentation is complete, so for those I would do a secondary in the keg, but not pressurize/carbonate.

On the other hand I am also planning on brewing a big barleywine in the near future, that I planned to bulk condition for 6 months or so, and for that one I will just transfer to a keg after primary, carb it up, and then let it sit.

Sounds right.

Brew on

- Joined

- Jan 14, 2015

- Messages

- 1,101

- Reaction score

- 316

Sounds right.

Brew on

Hah! I'm actually glad this thread popped up as I picked up 4 new ball lock kegs at a steal on one of the holiday sales with the intent of using them as secondaries. Then I realized I had no idea what I was doing and was going to have to ask the question myself!

Each brewer needs to decide for them self how OCD they want to be about minimizing TPO.

Brew on

Nothing OCD about it I reckon. Just makes sense to eliminate O2 or the possibility of O2. It's not hard and requires minimal kit.

I fill it till beer comes out the PRV.

Zero headspace.

Hook the keg to the gas and draw off beer till it's below the CO2 post and leave it alone at 34F and the desired CO2 pressure to force carbonate.

No additional purging needed. Simple.

Your method may not be a robust as you think it is. I measured the volume of my keg at overflow without the lid, and it's 5 - 5/16 gal (680 fl oz) as close as I can measure. I also measured the dead volume of the keg lid (upside down with the PRV open), and got 3 fl oz.Nothing OCD about it I reckon. Just makes sense to eliminate O2 or the possibility of O2. It's not hard and requires minimal kit.

I fill it till beer comes out the PRV.

Zero headspace.

Hook the keg to the gas and draw off beer till it's below the CO2 post and leave it alone at 34F and the desired CO2 pressure to force carbonate.

No additional purging needed. Simple.

So, if the keg contains air when you start racking the beer, you will have 3 fl oz of 210,000 ppm O2 gas in the lid headspace. If the beer comes in with zero dissolved O2, then the TPO from just that 3 fl oz is:

210000 ppm * 3 /680 = 926 ppm

Too much O2 for good storage stability according to some.Now if the keg contained mostly CO2 (StarSan forced out by CO2 prior to fill) when racking, the story would be much better. You start with the same amount of O2 with StarSan in the keg, but dilute the O2 by 3 / 680 after forcing it out with CO2. The net result is:

TPO = 210000 ppm * 3 / 680^2 = 1.36 ppm

(and some would say even that's too high.)Brew on

Great Work Doug

Keg contains CO2 when I rack

What's the dead space of the keg (lid on and sealed)filled with beer/starsan untill it comes out the PRV?

ETA: I see what your saying now. 3oz of predominantly CO2 filled deadspace is in theory trapped as a bubble at the top. Possible I suppose.

What are the numbers after pushing beer with CO2 till the level is below the gas tube. Usuall about 8 oz of beer is pushed out theis way I think. Perhaps a touch more.

I think at some fraction of 1.4ppm O2 I'm satisfied my beer is suitably stored. Thus far not a whisper of oxidation has been detected by impartial tasters of the beer. (Small but grown data set)

Keg contains CO2 when I rack

What's the dead space of the keg (lid on and sealed)filled with beer/starsan untill it comes out the PRV?

ETA: I see what your saying now. 3oz of predominantly CO2 filled deadspace is in theory trapped as a bubble at the top. Possible I suppose.

What are the numbers after pushing beer with CO2 till the level is below the gas tube. Usuall about 8 oz of beer is pushed out theis way I think. Perhaps a touch more.

I think at some fraction of 1.4ppm O2 I'm satisfied my beer is suitably stored. Thus far not a whisper of oxidation has been detected by impartial tasters of the beer. (Small but grown data set)

Great Work Doug

Keg contains CO2 when I rack

What's the dead space of the keg (lid on and sealed)filled with beer/starsan untill it comes out the PRV?

ETA: I see what your saying now. 3oz of predominantly CO2 filled deadspace is in theory trapped as a bubble at the top. Possible I suppose.

What are the numbers after pushing beer with CO2 till the level is below the gas tube. Usuall about 8 oz of beer is pushed out theis way I think. Perhaps a touch more.

I think at some fraction of 1.4ppm O2 I'm satisfied my beer is suitably stored. Thus far not a whisper of oxidation has been detected by impartial tasters of the beer. (Small but grown data set)

Yep the 3 oz bubble has to exist, as there is no way for the gas in that space to get out thru the PRV (or the gas or liquid posts for that matter.) Unless you vent the gas poppet, there will also be a bubble in the gas in tube. I didn't consider that last night, but it should be much less than the lid bubble.

Pushing excess beer out thru the dip tube doesn't remove any of the gas from the headspace. The original gas in the headspace gets diluted into the new, larger headspace volume, but the number of O2 molecules present doesn't change. Since TPO is total O2 molecules averaged over the total package volume, TPO won't go down unless you remove some of the O2 from the headspace.

I agree that 1.4 ish ppm TPO is probably good enough for most cases (especially if the beer is stored cold.) It is also probably much lower than most homebrewers (including me, my analysis skills are more advanced than my actual process skills) achieve with typical racking and bottling/kegging procedures.

Brew on

Sounds like I'll reincorporate a purge to my process.

Thanks again Doug for the images and thorough explanation. I really appreciate it.

Thanks again Doug for the images and thorough explanation. I really appreciate it.

Sounds like I'll reincorporate a purge to my process.

Thanks again Doug for the images and thorough explanation. I really appreciate it.

You're welcome. Just like you, I'm having fun.

Brew on

pretzelb

Well-Known Member

Each brewer needs to decide for them self how OCD they want to be about minimizing TPO.

Brew on

I wouldn't say OCD but it is more complicated than I'd prefer.

I wouldn't say OCD but it is more complicated than I'd prefer.

If you're happy with the quality of your beer, over the time it takes to drink it, then there's no need to change anything. I'm not really pushing to do anything specific, I just like doing the analysis and providing others with the information so that they can make informed decisions.

Brew on

If you're happy with the quality of your beer, over the time it takes to drink it, then there's no need to change anything. I'm not really pushing to do anything specific, I just like doing the analysis and providing others with the information so that they can make informed decisions.

Hey Doug,

I did about four or five brews where I filled the keg with starsan then removed via CO2 thus leaving a keg full of C02. I ferment in kegs so I can do closed system transfers. When I transfer I either need to leave the PRV open or sit there releasing it a number of times. I thought I read somewhere that diffusion happens quickly so that if I leave the PRV open the C02 in the receiving keg gets diffused with air. Because of this incomplete knowledge I stopped doing the water transfer. Could you provide any advice on whether it is worthwhile going back to water purging?

Thanks.

- Joined

- Jan 14, 2015

- Messages

- 1,101

- Reaction score

- 316

I think this thread represents everything I find great about these forums. One person asked a pretty straightforward question and received a great how-to from one very knowledgeable person and the science behind why it is like it is from another very knowledgeable person. In the end we had high res pictures, charts/tables, and lots of math!

Similar threads

- Replies

- 23

- Views

- 2K

- Replies

- 18

- Views

- 984

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)