jcc4507fly

Well-Known Member

- Joined

- Dec 27, 2012

- Messages

- 191

- Reaction score

- 17

Tops cut!! Still need to dull the edges. My old Boil Kettle lid fits perfect!!

Still hunting for a third keg.

I'm in the process of plugging my sight glass and I'll put etchings on the inside of my keggles, not sure how much better that is, but I'm close enough to hitting figures for what I want.

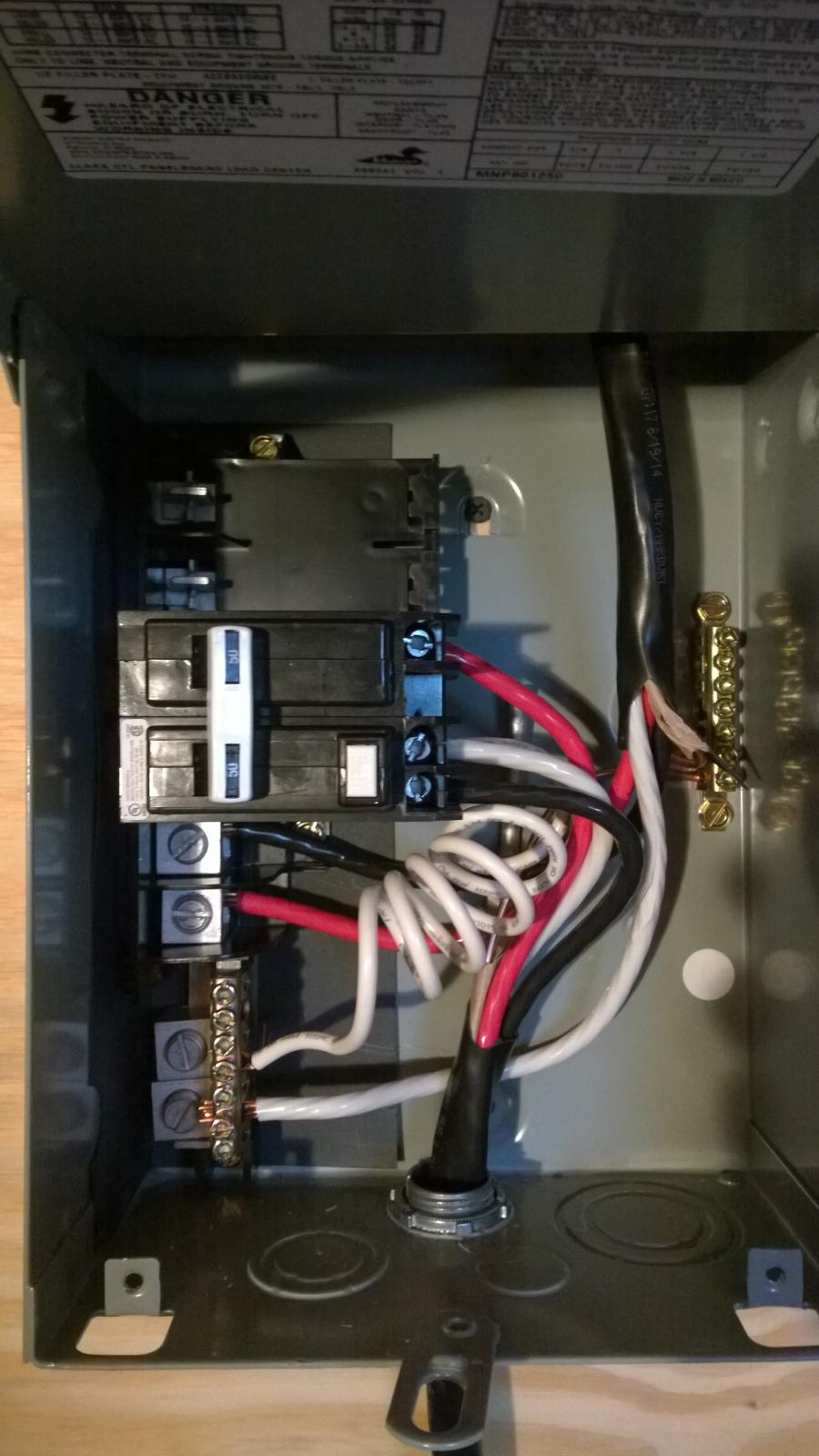

Also, it looks like this receptacle would be better... it says 3 wire, but I imagine it's ignoring the ground but still has a pin for it, right?

http://www.ebay.com/itm/NEW-Hubbell...244?pt=LH_DefaultDomain_0&hash=item43cf70682c

Thanks! Doesn't look like that one is locking. If I put this on the bottom of my control panel what's the likelihood that it falls out?go with this its quite a bit cheaper

http://www.ebay.com/itm/Marinco-CS6...497?pt=LH_DefaultDomain_0&hash=item1c3ce0bc39

Thanks BrokenHorn and carpenike!! I'm going to have to do that!!

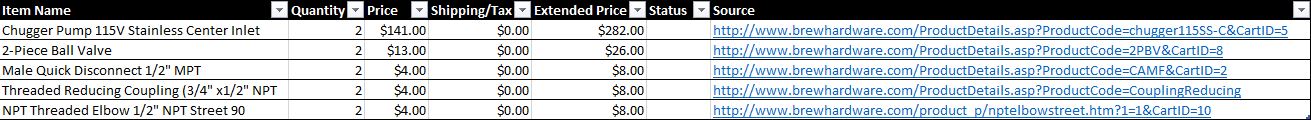

Alright I'm $1,200 poorer. I'm all in now.Keg parts on the way, will order pieces for the control panel this week.

Guess this will become my build thread as well.

Cool, thanks!

Did you guys build some type of jig to cut out the bottom or did you more freestyle it?

Also, what did you build your frame out of?

Thanks! Doesn't look like that one is locking. If I put this on the bottom of my control panel what's the likelihood that it falls out?

Any progress? I've been traveling a lot and busy when home. Have not had a chance to plan the build and order parts. I'd rather be at home working on this, but someone has to make some money to support this habit!!

Sent from my iPad using Home Brew

Wouldn't have thought it would have been so hard to find pot lids. Picked up three of these:

http://www.foodservicewarehouse.com/supera/ap-20c/p1515596.aspx