Ok I think i want to upgrade my brewing process of cooling the wort down and filtering it. Im doing all extract brewing right now until i get enough experience to move up to all grain.

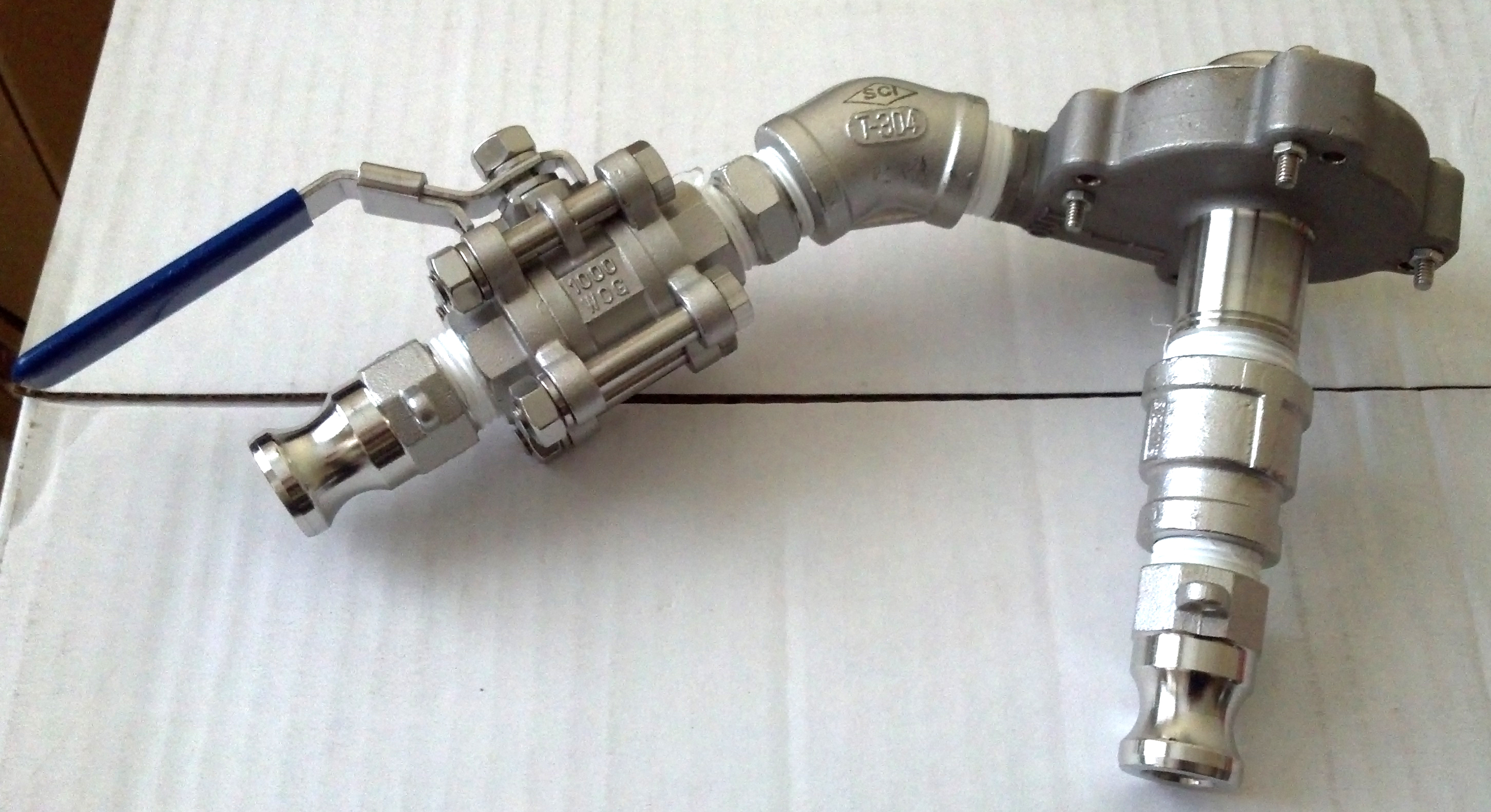

I want to add a filter to my system and i would like to use a plate chiller instead of a copper worm.

I have 2 questions im brewing 5 gallon batches right now. how big of a plate chiller should i use to cool it down to correct temp with tap water out of the faucet. Also what kind of pump should i get for it.

question for filtering. Should I filter before i put it before the plate chiller or after before it goes into the fermentation bucket. Will the filter get clogged before all the wort passes threw or will the pump force it threw. I will have all the hops left over from the boil from the pellets and other steeping grains leftover that escaped the tea bag.

I want to add a filter to my system and i would like to use a plate chiller instead of a copper worm.

I have 2 questions im brewing 5 gallon batches right now. how big of a plate chiller should i use to cool it down to correct temp with tap water out of the faucet. Also what kind of pump should i get for it.

question for filtering. Should I filter before i put it before the plate chiller or after before it goes into the fermentation bucket. Will the filter get clogged before all the wort passes threw or will the pump force it threw. I will have all the hops left over from the boil from the pellets and other steeping grains leftover that escaped the tea bag.