Hi Brew Heads!

So about 7 months ago, equipped with a shoe string budget I began the conversion to a Herm's rig. I acquired 3 kegs, converted them to keggles and did some various polishing efforts on all 3. So for the HLT, I used sharkbite connections to get my coil connected to the walls of the keggle.

Again, with a budget I purchased one chugger pump, and a couple mini pumps which are supposed to be foodgrade and high temp, I only plan to use them for hot water, sparging and such.

Here is where my rig deviates from the norm. My brother works for a lab that had heating elements, probes and control units. He was able to get me enough elements for the HLT and BK, two probes and a control unit. Now these devices were designed for an oven that heated microchips to test for failures. With his control unit, I have to use 4 elements, two in each keggle. They are long and unwieldy, and had to be mounted vertically. I do so in a not permanent fashion, as you can, they dangle. Right now, everything is at 115v, so my elements are heating on the slow side.

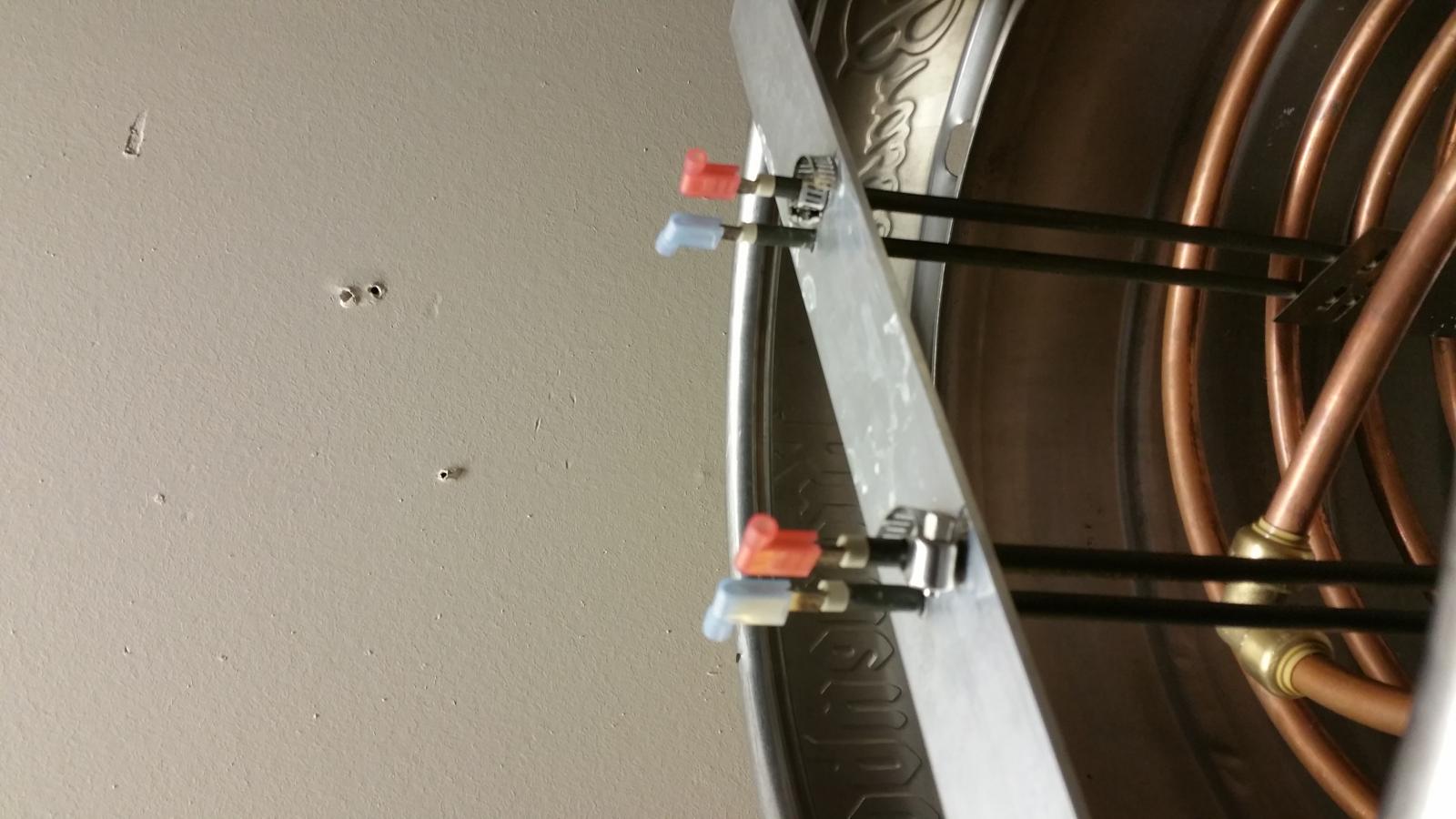

The control unit talks to a computer, via null modem cable. We have written software to read temps and set temps on both keggles. That part is done. We wired everything in a temp fashion to prove the theory, which was proven. Pictured is how I put in conduit to accommodate this beastly rig, now I am down to terminating leads and connections before hopefully running a simulated batch this weekend.

I know most of you probably never have seen such a ghastly looking rig, but for a sticker price of about $700 total invested, it might just be my poor man's Brutus.

Does anything jump out right away to any of you? Comments? Concerns?

Thanks all,

Joe

So about 7 months ago, equipped with a shoe string budget I began the conversion to a Herm's rig. I acquired 3 kegs, converted them to keggles and did some various polishing efforts on all 3. So for the HLT, I used sharkbite connections to get my coil connected to the walls of the keggle.

Again, with a budget I purchased one chugger pump, and a couple mini pumps which are supposed to be foodgrade and high temp, I only plan to use them for hot water, sparging and such.

Here is where my rig deviates from the norm. My brother works for a lab that had heating elements, probes and control units. He was able to get me enough elements for the HLT and BK, two probes and a control unit. Now these devices were designed for an oven that heated microchips to test for failures. With his control unit, I have to use 4 elements, two in each keggle. They are long and unwieldy, and had to be mounted vertically. I do so in a not permanent fashion, as you can, they dangle. Right now, everything is at 115v, so my elements are heating on the slow side.

The control unit talks to a computer, via null modem cable. We have written software to read temps and set temps on both keggles. That part is done. We wired everything in a temp fashion to prove the theory, which was proven. Pictured is how I put in conduit to accommodate this beastly rig, now I am down to terminating leads and connections before hopefully running a simulated batch this weekend.

I know most of you probably never have seen such a ghastly looking rig, but for a sticker price of about $700 total invested, it might just be my poor man's Brutus.

Does anything jump out right away to any of you? Comments? Concerns?

Thanks all,

Joe

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)