Why do you think efficiency is so low? Doesn't CBS advertise getting over 80%? I've been seriously considering purchasing a 1bbl Dual for some time, but under 70% efficiency would be a deal killer.Sure, Ive attached a screenshot of the equipment profile page. My next batch I'll be changing the efficiency to 68% it's currently set to 67%. I only have a 1 gallon boil off because I use a steam condenser that allows me to boil with the kettle lid on. I also changed the BIAB Grain Absorption to 0.8000 fl oz/oz.

View attachment 609413

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unboxing the Nano from CO Brewing

- Thread starter pretzelb

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

30Bones

Well-Known Member

Nothing really wrong with it, it's just not needed and you measure the temp in the grains 6" down compared to what the probe reads right next to the element you will see 6 degrees or more of a temp swing. For me the cooler was a solution to a problem. Again, still love my setup and would buy it again...minus the basket, frame, hoist.What is wrong with the recirculation process? I'm hitting my pre-boil gravities, beer is turning out just as good if not better then when I used a cooler. I can maintain a constant mash temp. I'm very happy with the CBS setup. It did take some time to fine tune it to BeerSmith, but now that I've got that figured out everything is good.

Why do you think efficiency is so low? Doesn't CBS advertise getting over 80%? I've been seriously considering purchasing a 1bbl Dual for some time, but under 70% efficiency would be a deal killer.

My BHE is roughly 68-70% as well, and to make it even more interesting, complete conversion takes me 90 minutes. That was really surprising.

Since I do adjust mash pH I am left suspecting my crush quality as the main culprit. My crush is whatever I get from the LHBS because I don't have a mill yet.

Another factor is perhaps my batch size. I do 5 gal batches in a 20 gal COBS kettle, so I have FOUR GALLONS below the basket and the mash in the basket is very thick. The one time I made a mistake and had more water and a looser mash, both mash and BHE shot up.

They say that it isn't supposed to matter, that it is only the total water:grain ratio, no matter how they are split up... but that is what I saw.

Anyway if you are milling yourself and doing normal sized batches I bet you will be OK.

jahlinux

Well-Known Member

- Joined

- Dec 16, 2015

- Messages

- 157

- Reaction score

- 44

Why do you think efficiency is so low? Doesn't CBS advertise getting over 80%? I've been seriously considering purchasing a 1bbl Dual for some time, but under 70% efficiency would be a deal killer.

Not sure, but now that I have repeatability I’m going to leave well enough alone. The last few batches were coming in just under 70% efficiency. I think for recipe development 68% will work out best. The only thing I can think of is possibly the crush. If I crush any finer I don’t think I’ll have decent recirculation. Also I find I get complete conversion within a normal 60 minute mash.

One thing to remember here, is how old are some of these CBS systems. They changed to a 600 micron screen in the basket sometime in 2018, which has eliminated these stuck mashes and flow problems. I can run my pump full throttle no issue at all, which also solves the temp stratification some are reporting.

jabba11

www.CeeGeeBrewing.com

interesting because I have the exact system you described. I don't have ANY of these problems. I will say if you make high alcohol beers in small batches its possible to have these problems though. I wont go into possible solutions because Ill assume you've read them all hereI have a 20 gallon basket, stainless frame and pulley setup for sale if anyone is interested that is wanting to DIY a setup like this

- Mash re circulation (IMHO it's not needed) created a lot of issues from wort not getting through the bed fast enough to starve the element and fry it (multiple times) if you walked away for a hot minute, along with massive temp differences, constant stirring of the grains to keep the flow going no matter the grain crush it seemed. My basket is the solid sided, mesh bottom. Pump has always been my old chugger. I sent the silly pump it came with back once I unboxed it.

- Constant pump adjustment and babysitting. I think it leaves a lot to be desired. Some love it, I liked it, but far from love

- Efficiency was always all over the map and hitting my numbers was never consistent.

- Stainless basket is/was a PITA to clean

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

jabba11

www.CeeGeeBrewing.com

my system is pre 18 and I don't have any serious sticking issues. lots of rice hulls and a sac rest with wheat and adjustment of the grind. I consistently get 82%One thing to remember here, is how old are some of these CBS systems. They changed to a 600 micron screen in the basket sometime in 2018, which has eliminated these stuck mashes and flow problems. I can run my pump full throttle no issue at all, which also solves the temp stratification some are reporting.

That’s great. Reading through this thread there are plenty of older posts with people reporting stuck mashes, flow issues, playing with crush size, rice hills, teeing the flow of through the whirlpool port, etc. I’ve been to the CBS shop and the guys specifically told me they changed to a bigger 600 micron screen to fix those problems. I can report no rice hulls, coarse crush,my system is pre 18 and I don't have any serious sticking issues. lots of rice hulls and a sac rest with wheat and adjustment of the grind. I consistently get 82%

Ssbrewtech manifold, choked flow needed with the new basket.

My post was directed at the person who just asked why the efficiency is so bad, sorry I should of quoted it. The smaller screens they used before had people using a coarser crush and restricting recirculation to avoid flow issues. With the new screen you can crush to normal biab fine size and get the 80% efficiency.

jabba11

www.CeeGeeBrewing.com

honestly if it helps with flow I wish mine was one LOL. I cant say I just dump and walk away. You have to be vigilant with mine especially with wheat and or large grain bills. Crush size CAN be a problem as well but Ive dialed mine in and I think in general that's what it takes. You have to find the right way to use it. If you make high alcohol beers the system can be limiting imho. And by high alcohol I mean like 8% or greaterThat’s great. Reading through this thread there are plenty of older posts with people reporting stuck mashes, flow issues, playing with crush size, rice hills, teeing the flow of through the whirlpool port, etc. I’ve been to the CBS shop and the guys specifically told me they changed to a bigger 600 micron screen to fix those problems. I can report no rice hulls, coarse crush,

Ssbrewtech manifold, choked flow needed with the new basket.

My post was directed at the person who just asked why the efficiency is so bad, sorry I should of quoted it. The smaller screens they used before had people using a coarser crush and restricting recirculation to avoid flow issues. With the new screen you can crush to normal biab fine size and get the 80% efficiency.

Thanks! That's good to know that CBS fixed some issues and that the newer systems don't have the same problems. I think another issue the individual who reported under 70% might be having is less than a full capacity batch. HIs attachment indicated he was only putting 12 gallons into the fermenter with a half barrel system. With the smaller batch there's a considerable percentage of his mash liquid under the basket. Not sure if that could be impacting his efficiency issues.That’s great. Reading through this thread there are plenty of older posts with people reporting stuck mashes, flow issues, playing with crush size, rice hills, teeing the flow of through the whirlpool port, etc. I’ve been to the CBS shop and the guys specifically told me they changed to a bigger 600 micron screen to fix those problems. I can report no rice hulls, coarse crush,

Ssbrewtech manifold, choked flow needed with the new basket.

My post was directed at the person who just asked why the efficiency is so bad, sorry I should of quoted it. The smaller screens they used before had people using a coarser crush and restricting recirculation to avoid flow issues. With the new screen you can crush to normal biab fine size and get the 80% efficiency.

Regarding higher ABV beers, what is the issue there? Too tall of a grain bed?

jabba11

www.CeeGeeBrewing.com

yes If you are brewing say a "5 gallon batch" in the 20 gallon system and shooting for an 8% beer or something like that the grain bill would most likely be above the water. Not sure about a 10 gallon batch. Honestly I don't brew beers that big anymore. Also I always brew 7 gallons or better even if I am only brewing a five gallon batch just as a preventative but mostly I brew 10 gallons in which case I brew an 11 gallon batch and do so to account for losses for dumping tasting etc.Thanks! That's good to know that CBS fixed some issues and that the newer systems don't have the same problems. I think another issue the individual who reported under 70% might be having is less than a full capacity batch. HIs attachment indicated he was only putting 12 gallons into the fermenter with a half barrel system. With the smaller batch there's a considerable percentage of his mash liquid under the basket. Not sure if that could be impacting his efficiency issues.

Regarding higher ABV beers, what is the issue there? Too tall of a grain bed?

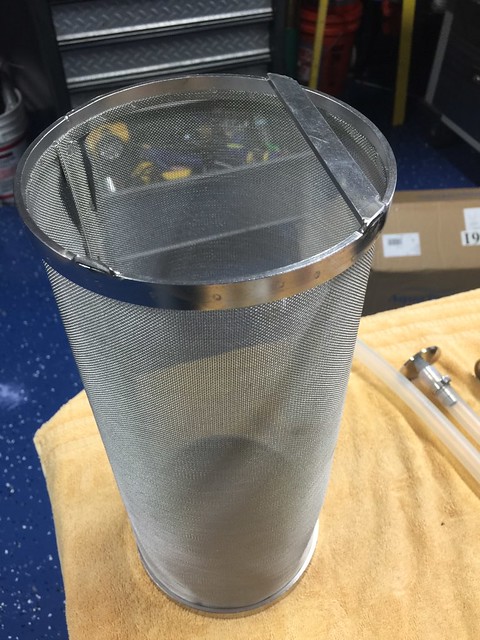

Here is my hop basket mod. I ordered the 500 micron from Bobby at Brew Hardware. He has 300, 500, and 800 micron.

I attached a 33lb super magnet to the basket with JB Weld.

I then used a Dremel tool to cut off the hangars on the basket.

Here it is installed in the kettle allowing the lid to seal completely. It is rock solid and actually a little difficult to remove. The magnets are incredible. I may add a little felt to the outside magnet to make removing it easier. Infinite height adjustment too!

Nice -- and just what I need! Are these magnets still "holding up" well? The only ones I can find have a working temp. limit of 176F (e.g. DIYMAG Neodymium, 60x10x5 mm). (It is also specified as having a 33lb AND 12lb strength!?). Can you tell me where to find these RE magnets which will work at boil temps? Many thanks!

Nice -- and just what I need! Are these magnets still "holding up" well? The only ones I can find have a working temp. limit of 176F (e.g. DIYMAG Neodymium, 60x10x5 mm). (It is also specified as having a 33lb AND 12lb strength!?). Can you tell me where to find these RE magnets which will work at boil temps? Many thanks!

Let me reply to my own query. You should NOT use the standard N45 magnets typically found on-line, which are only good to 176F. Instead, use the N42SH ("super high" temp) version, which are good up to 300F. About the same strength and price. Found mine at TotalElement, 2" x 1/2" x 1/2". A little larger (thickness) than alternatives, but quite a bit less expensive (when including shipping) than the 1/8th and 1/4 width magnets I could find, and should probably be a little easier to "twist off" the kettle than the flatter magnets.

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

Magnets are holding up fine. I found its better to use a silicone adhesive than JB weld,

That's good to know -- don't want that spider slipping down into the boil kettle! Thanks for the silicone adhesive tip.Magnets are holding up fine. I found its better to use a silicone adhesive than JB weld,

Been a while since we had any posts in this thread! Still using my 2016 Nano Home, still pretty happy with it. But I have started monitoring the temperature deep inside the grain bed, and it is easy to see that it takes 10-15 minutes for the temperature in the grain to match what I see on the control panel. So, when I mash out, or do a protein rest... I am not hitting the temperature that I programmed.

Others have posted that the company switched to a more coarse mesh in the basket to let us pump faster, and thereby make faster temperature changes. Has anyone had their basked modified to the new mesh standard? Is this worth pursuing? I asked the company what the cost for a modification or new basket purchase would be, but if anyone has actually tried this I would like to know if it actually helped.

Others have posted that the company switched to a more coarse mesh in the basket to let us pump faster, and thereby make faster temperature changes. Has anyone had their basked modified to the new mesh standard? Is this worth pursuing? I asked the company what the cost for a modification or new basket purchase would be, but if anyone has actually tried this I would like to know if it actually helped.

Last edited:

akthor

Well-Known Member

I got sick and tired of trying to get decent flow during mash and more importantly getting it to drain with the damn basket. Wort levels and efficiencies were all over the place and dealing with 1bbl batches it's not like you can afford to keep doing batches quickly to figure it out. So I gave up on BIAB and I purchased a 1bbl Mash Tun from Spike.

I believe I had an OG basket with the really fine mesh. It just didn't work well. I decided I missed the easily dialed in and repeatable Mash Tun method so I went back to it.

Buying a new basket would have costed 1/2 at least of what going to the mash tun costs so....

I believe I had an OG basket with the really fine mesh. It just didn't work well. I decided I missed the easily dialed in and repeatable Mash Tun method so I went back to it.

Buying a new basket would have costed 1/2 at least of what going to the mash tun costs so....

pretzelb

Well-Known Member

I switched out the basket for a Wilser bag. I had to get a custom false bottom but so far it has worked. I did get scorching on my last batch but it was my fault. It was a 10g batch heavy with wheat and rye with zero rice hulls. I kept an eye on the sight glass and started to doubt it was correct after watching slowly go down. I thought maybe the bag just clogged the opening. But the entire bottom was going dry after 45 minutes. To be fair, all I had to do was stop the pump, close the valve a bit, and then keep going. Past brews have been good with pump going near full speed. Clean up is much easier with the bag.Been a while since we had any posts in this thread! Still using my 2016 Nano Home, still pretty happy with it. But I have started monitoring the temperature deep inside the grain bed, and it is easy to see that it takes 10-15 minutes for the temperature in the grain to match what I see on the control panel. So, when I mash out, or do a protein rest... I am not hitting the temperature that I programmed.

Others have posted that the company switched to a more coarse mesh in the basket to let us pump faster, and thereby make faster temperature changes. Has anyone had their basked modified to the new mesh standard? Is this worth pursuing? I asked the company what the cost for a modification or new basket purchase would be, but if anyone has actually tried this I would like to know if it actually helped.

I talked with CBS about the basket update and it is good news. They will modify your basket for free, you just pay shipping. They will also help you ship on their commercial account which should save you some money over going to the UPS Store. The modification takes a couple of days.

I will probably do this as soon as I can figure out how to package my basket.

I will probably do this as soon as I can figure out how to package my basket.

pretzelb

Well-Known Member

What's the update exactly?I talked with CBS about the basket update and it is good news. They will modify your basket for free, you just pay shipping. They will also help you ship on their commercial account which should save you some money over going to the UPS Store. The modification takes a couple of days.

I will probably do this as soon as I can figure out how to package my basket.

They replace the mesh bottom with a more coarse mesh as used in current production. I don't know the specs, but they are in this thread somewhere.

I thought I didn't have problems until I stuck a probe into the mash.  The temperature in there lags 10 minutes behind the system's probe in the liquid. Not a big deal for a 60 minute step, but it isn't great for a 10 minute step!

The temperature in there lags 10 minutes behind the system's probe in the liquid. Not a big deal for a 60 minute step, but it isn't great for a 10 minute step!

jabba11

www.CeeGeeBrewing.com

I have done this too, in fact many times. After dough in once min reaches temp if it drops at all I stir once it reaches temp again. Maybe once more. the bed is never more than a degree off or so. if I am step mashing I wait till it reaches temp and stir, then maybe stir again in 5 mins or so. it should be noted I don't do high abv beers though. stirring helps with this I guess it what I am saying. If you hasve a rims or something else you are gonna have lag as well no matter what.

1\

1\

I thought I didn't have problems until I stuck a probe into the mash.The temperature in there lags 10 minutes behind the system's probe in the liquid. Not a big deal for a 60 minute step, but it isn't great for a 10 minute step!

Makes sense. I will upgrade the mesh and see what the lag time is like. If stirring has to happen, so be it.

I just updated my PLC software to the newest version. There are 2 new "max output" settings in the PID settings, each of which comes set to 0%.

The release notes just say that these values "need to be set" without giving any other guidance.

I assume that this is the maximum power output allowed in the mash and overall, but I have no idea what wise values are. Before I contact the company, has anyone already figured this out?

The release notes just say that these values "need to be set" without giving any other guidance.

I assume that this is the maximum power output allowed in the mash and overall, but I have no idea what wise values are. Before I contact the company, has anyone already figured this out?

Can anyone confirm the PID settings on their Nano Brewer?

This morning when I went to brew, my system wouldn't heat up... After some wasted time with the multimeter I found that the new Max Output settings had both reset themselves to 0%.

Now, I am a little worried my PID settings may have changed, too. This is what I have... Does it look like yours?

This morning when I went to brew, my system wouldn't heat up... After some wasted time with the multimeter I found that the new Max Output settings had both reset themselves to 0%.

Now, I am a little worried my PID settings may have changed, too. This is what I have... Does it look like yours?

jabba11

www.CeeGeeBrewing.com

I know its not any help but its when I see this kind of stuff that I am glad I have just a PID and switches. gotta admit it would be nice to program changes but not sure I want the headacheCan anyone confirm the PID settings on their Nano Brewer?

This morning when I went to brew, my system wouldn't heat up... After some wasted time with the multimeter I found that the new Max Output settings had both reset themselves to 0%.

Now, I am a little worried my PID settings may have changed, too. This is what I have... Does it look like yours?

View attachment 648059

Similar threads

- Replies

- 11

- Views

- 706

Colorado

Nano Homebrew System (10-15 Gallons)

- Replies

- 0

- Views

- 766

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)