- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

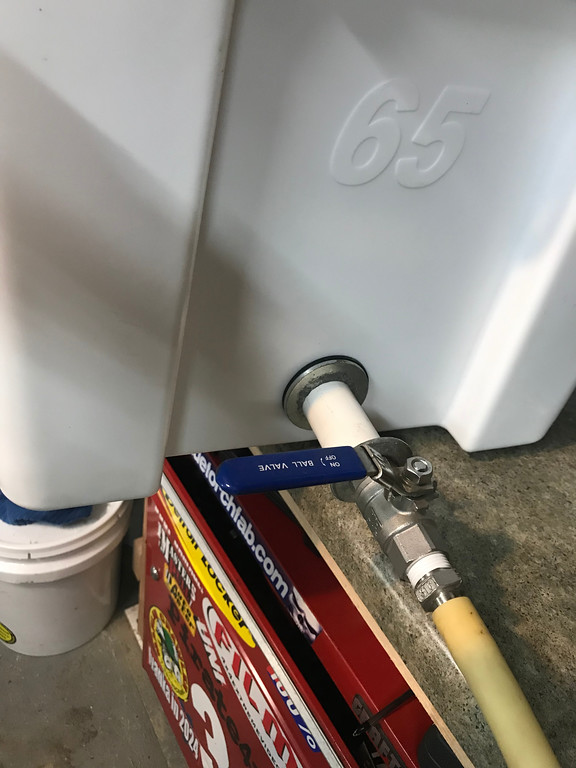

3 gallons under. I had a port under the basket and a diy recirc arm on top. It was better circulation in both places during the mash but different grain bills really messed with the flow rate and as a result the temp control parameters.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)