Sunday I fired up the Nano Home for another batch of Yooper's oatmeal stout. Brew day was pretty uneventful with 2 small exceptions. One, I forgot to do the CBS-recommended 113F rest to make flaked oats less gummy. Two, I ended up half a gallon short pre-boil, possibly due to #1. My mash efficiency was also lower than expected despite rinsing with the missing half-gallon.

Still trying to get the numbers dialed in on this system... It does seem very sensitive to mash thickness. In this case I was using 8.35 gal water to 12.1 lb grain.

A thick mash means lower efficiency, but a thin mash means you might have to boil off a lot of water, which has its own issues. I am curious how you other 5 gallon guys are calculating your water volumes. I thought I had a BeerSmith "BIAB Grain Absorbtion" value that worked for me but I'm coming in low now. I don't really care what my efficiency is, as long as I can make it consistent. (This batch was 73% I think; last batch was 93% because I goofed up there too and somehow got too much water in, making the mash really fluid.)

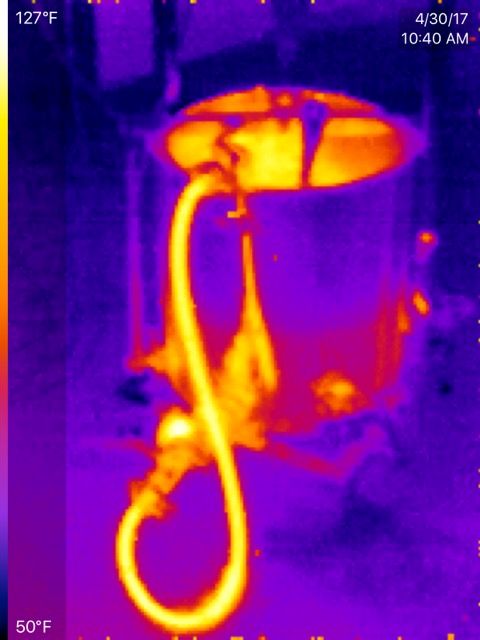

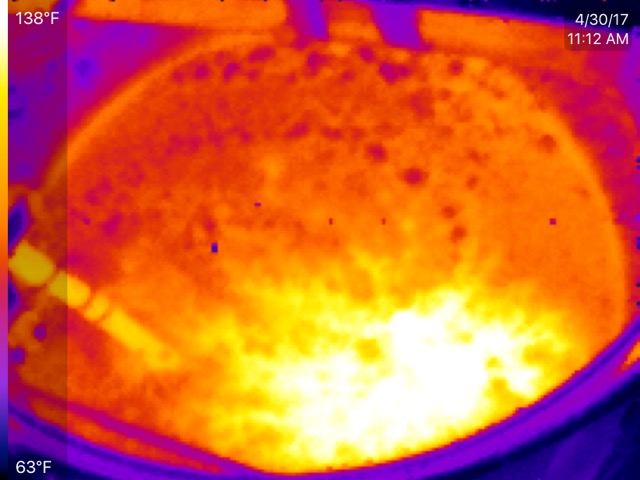

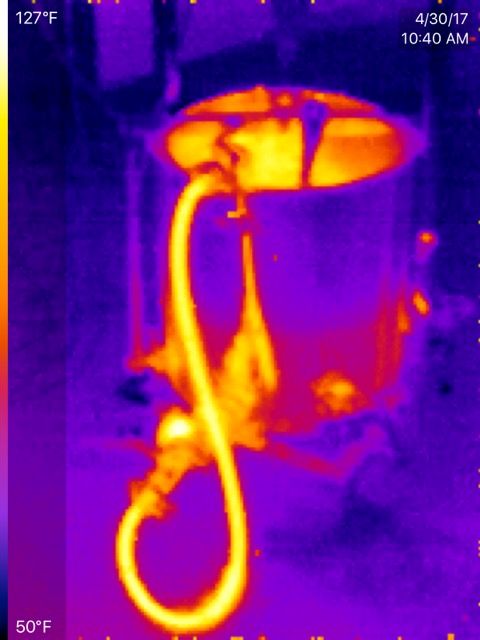

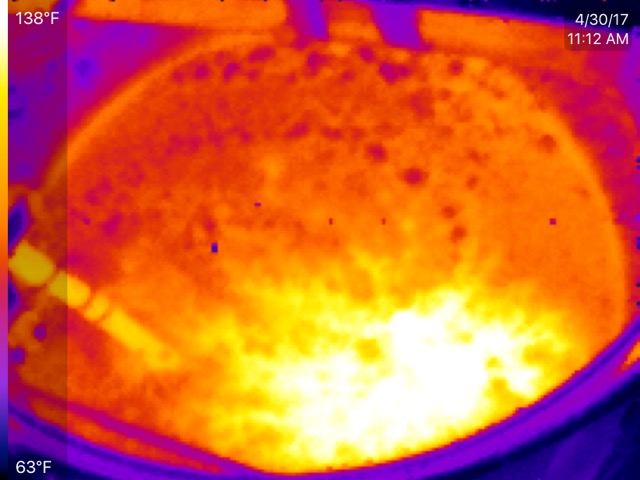

This time I remembered to play with my thermal camera, so here are some pictures. My thermal camera is cheap and lame--do not trust any temperatures in the photos! However, you can evaluate relative temperatures between two areas provided that they are the same material.

Kettle image, useless but fun.

Top of the mash. The bright spot is an area where liquid wort has pooled. Water reads hotter than wet grain at the same temperature so this isn't apples to apples.

Here's a little video clip of the same area: https://gfycat.com/HollowYellowAdeliepenguin

When probing the grain bed with my Thermapen I saw temperatures between 156F (target temp, deep in the grain bed near the under-basket liquid) and 149F (farthest away from the recirc return, top of the grain bed). When I stirred the mash, I could hear the element kick on, as the cooler liquid got back into circulation. I'm convinced that a manifold like the Ss Brewtech model that some of you use is a good idea.

(Oh, my replacement element did not have a hot spot near the base, either.)

Still trying to get the numbers dialed in on this system... It does seem very sensitive to mash thickness. In this case I was using 8.35 gal water to 12.1 lb grain.

A thick mash means lower efficiency, but a thin mash means you might have to boil off a lot of water, which has its own issues. I am curious how you other 5 gallon guys are calculating your water volumes. I thought I had a BeerSmith "BIAB Grain Absorbtion" value that worked for me but I'm coming in low now. I don't really care what my efficiency is, as long as I can make it consistent. (This batch was 73% I think; last batch was 93% because I goofed up there too and somehow got too much water in, making the mash really fluid.)

This time I remembered to play with my thermal camera, so here are some pictures. My thermal camera is cheap and lame--do not trust any temperatures in the photos! However, you can evaluate relative temperatures between two areas provided that they are the same material.

Kettle image, useless but fun.

Top of the mash. The bright spot is an area where liquid wort has pooled. Water reads hotter than wet grain at the same temperature so this isn't apples to apples.

Here's a little video clip of the same area: https://gfycat.com/HollowYellowAdeliepenguin

When probing the grain bed with my Thermapen I saw temperatures between 156F (target temp, deep in the grain bed near the under-basket liquid) and 149F (farthest away from the recirc return, top of the grain bed). When I stirred the mash, I could hear the element kick on, as the cooler liquid got back into circulation. I'm convinced that a manifold like the Ss Brewtech model that some of you use is a good idea.

(Oh, my replacement element did not have a hot spot near the base, either.)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)