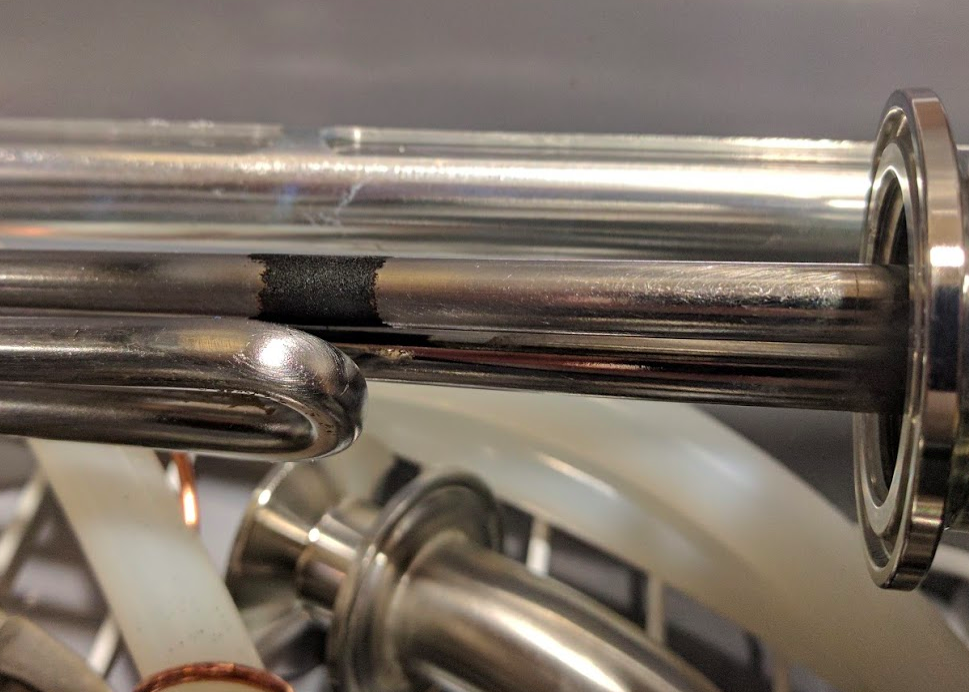

After my last batch I found a scorch mark on my element. This one little spot has always been hotter than the rest of the element--it collects browned gunk, while the rest of the element stays clean. The browned part is still easy to clean so I haven't worried about it. But the spot seems to be getting even

hotter now, since it turned black and crusty!

Are hot spots normal for electric elements? I'll be relieved if someone says yes, but this doesn't look right to me, especially since it's been changing over time.

FYI my boil maintain power is 65% with about 7.5 gal in the kettle. I have the PLC system so the switch from 100% to maintenance power happens automatically when the kettle hits 207.6 F -- thanks to the automation there's no chance I did something differently on this batch to make this happen.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)