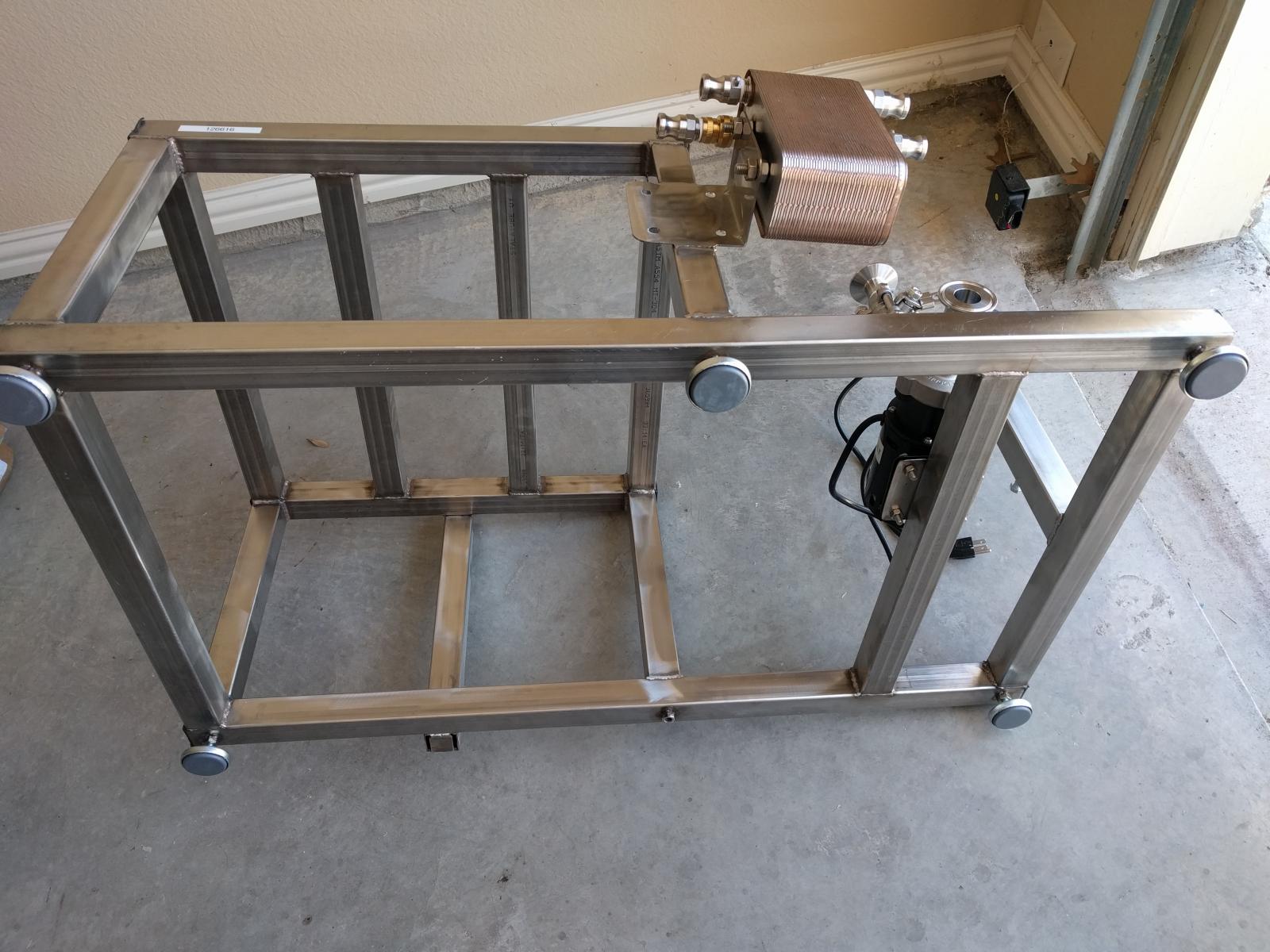

My new 20g Nano brew system arrived. I still need to get the outlet installed so it will be a while before I can brew. Just thought I'd document the install.

View attachment 1457884728038.jpg

View attachment 1457884748930.jpg

View attachment 1457884728038.jpg

View attachment 1457884748930.jpg

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)