Another brew day down. Since I was trying to verify best practices and BeerSmith settings I did a familiar recipe, a simple pale ale. Everything worked out great. I set my estimated brewhouse efficiency at 75% based on my last batch, and hit 73.3%. Target OG was missed by 1 point. Estimated mash efficiency was 78.3%, actual was 77.9%. Close 'nuff. (All my BeerSmith settings for the Nano Home 20 gallon version are in

this previous post.)

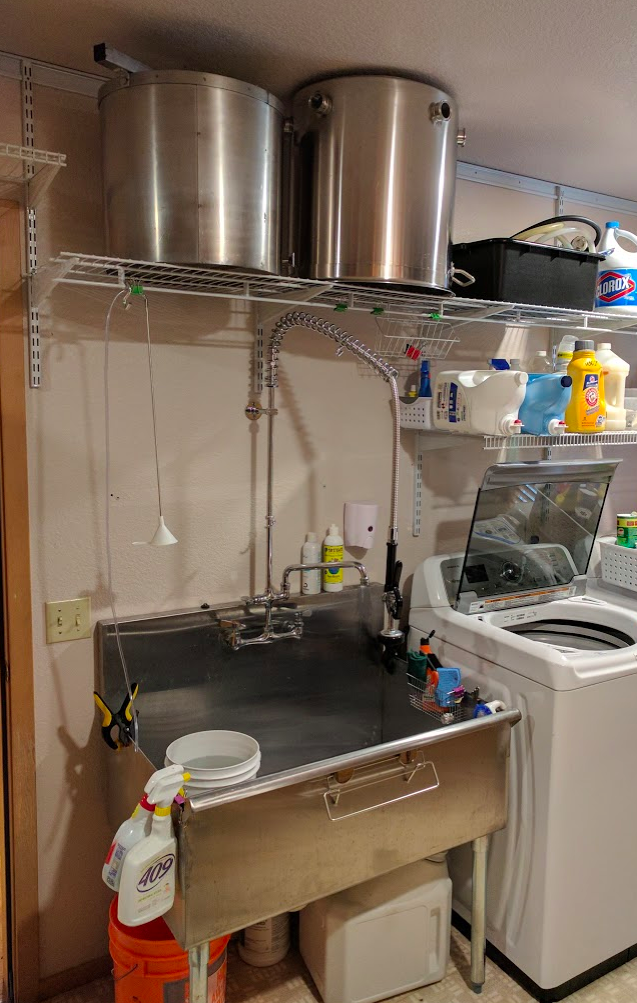

This is the mash after about 40 minutes but it was starting to clear noticeably by 20 minutes. I did not stir at all after mashing in--just set the manifold on top and let the pump run. I started at about 20% speed and moved up to about 30-40% speed after ~30 minutes. That was as fast as I could go without overdoing it.

I tried one new thing this time, which was stirring the heck out of the mash just before draining. It did not seem to make a difference. Mash efficiency was 77.9%, but on my last batch when I did not stir before draining, it was 78.6%. The beers were not identical, but had similar amounts of grain and gravities.

As before I ended up about 1/2 gallon short after draining, and did a small cold water pour-over rinse. I know I did a lousy job of distributing the water evenly so there is room for improvement here.

The wort in the kettle was very cloudy. For the sake of @TexasWine I will get a picture of my next batch after draining but without stirring the mash beforehand. I don't expect it to be too pretty though.

Wish I had another fermenter, I want to brew again already!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)