So.....I finally re-read your original post and realized that you said to just replace the bottom pan....that's what I'm going to do now. Sorry for not listening the first time (maybe my wife is right about me not listening??? Lol)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

True TDD-2 Kegerator remodel/touchup

- Thread starter kchomebrew

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jasonvincent

New Member

- Joined

- Jan 27, 2013

- Messages

- 1

- Reaction score

- 0

I've recently acquired a TDD-3 from my father-in-law. It is awesome as is this post for tips on working on them. My evap pan is leaking, so I have a project in my future.

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

lonerunman

Member

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

Hi Jason - I insulated my tower with some spare blue camping sleeping pad that I had kicking around. It's that cheap pad that most outdoorsy stores sell, but you could use any similar closed-cell foam you find.

After installing my shanks, tailpieces and lines, I cut the foam to length and with enough width to wrap inside the tower. I was able to shove the foam up the length of the tower since it was stiff enough. Voila!

As for the cap, I jammed some bubble wrap into the top of the tower, trying to get it down and around the tailpiece, then popped the cap back on. I'm a little tight for space in there because I doubled up my taps (it came with one tap per tower, and I added a second tap to each - yeah!).

Overall it works pretty well, but I do get a bit of condensation around the shanks and at the bottom of the towers where they are mounted into the fridge unit. I guess there's not much/any insulation at these points.

But most importantly, the beer flows out fine without foaming

Hope that helps. What have others done to insulate their towers?

Bruce

p.s. what an awesome fridge, isn't it? Mine's an old renovation recovery as well - it was going to the landfill but all it needed was a serious cleanup and a new fan. I still need some new door seals, but dang they're spendy!

philipCT

Brewniversity student

- Joined

- May 10, 2013

- Messages

- 771

- Reaction score

- 171

...

Questions about your tap tower upgrade, what did you use to insulate the inside of the tower? Do you experience any condensation? Do you hang your hoses at the top of the vertical sections of the tower, or try to extend them into the horizontal section?

Well good luck with that evap pan repair!

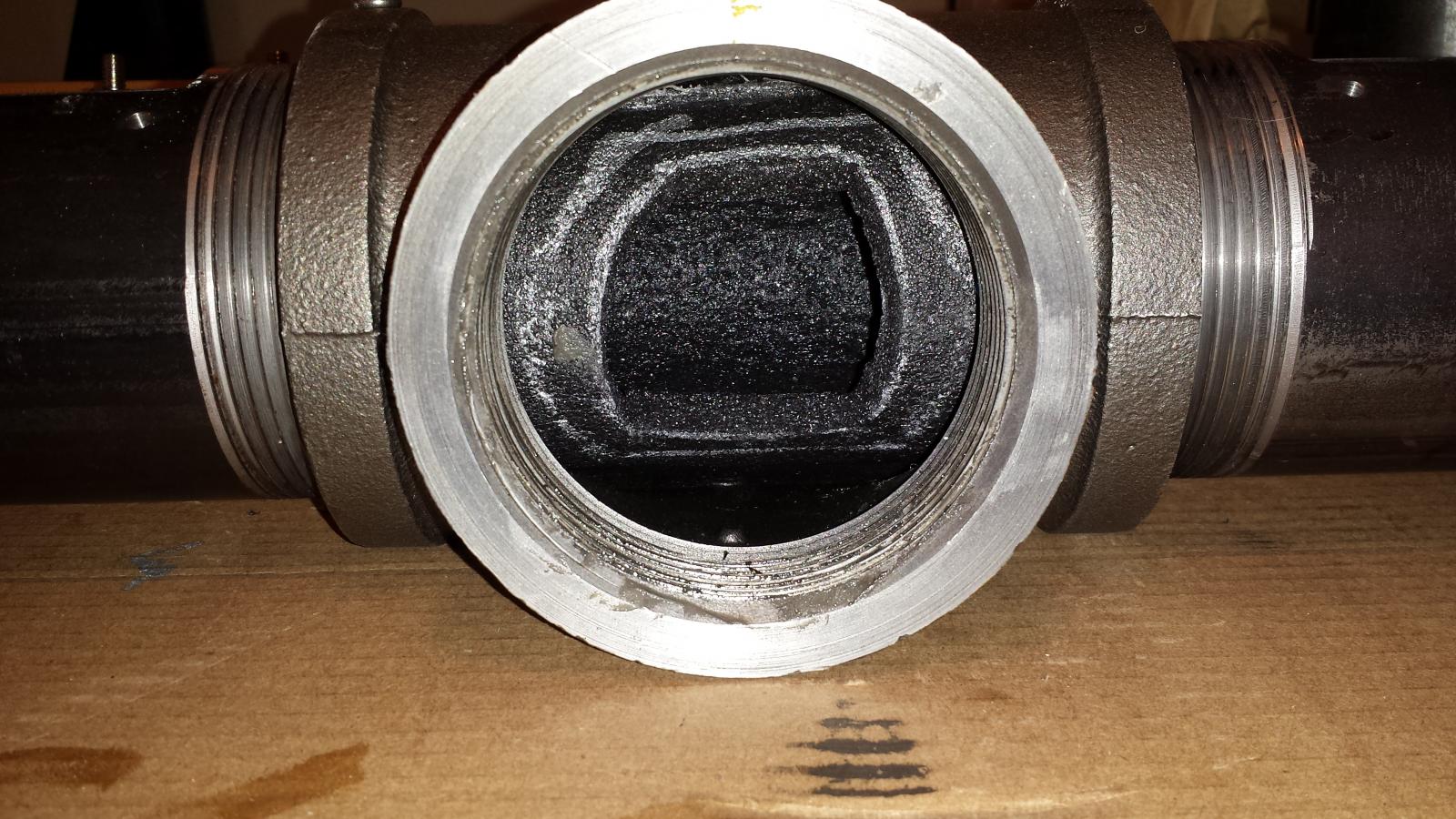

re: insulation - I found cylinders of closed cell foam that were about 2" in diameter. I did a fair amount of cutting and gluing to make several pieces that fit nice and tight around everything. Hope these pics help but LMK if you have any questions.

I don't get any condensation on the pipes. They are definitely cold to the touch though.

Here's what I ordered from Zoro:

Zoro Item Product Name Description Shipping Unit Price Qty. Amount

G1242552 Closed Cell Pipe Insulation Pipe Insulation,2 In. ID,6 ft. L,Black Expedited Shipping Available $4.07 2 $8.14

Subtotal $8.14

Shipping $5.00

Tax $0.84

Total $13.98

bdawgbrewer

New Member

- Joined

- Aug 15, 2019

- Messages

- 2

- Reaction score

- 0

k

Going to bring this convo back almost 10 years later... I have a TDD-1 that I also have to replace the evap tray. For those who did this, did you end up using any kind of rubberized spray (sealant) to the tray for longevity or was it unnecessary?

Also, have any of you had to deal with any kind of acetone smell coming from the fridge? I get a whiff sometimes when I walk by it. It isn't a refrigerant leak, so I'm not 100% sure what it is. My old man thinks it might be the compressor heating up old paint or glue, or possibly dust. There is also plumber's putty it seems holding two sheet metal pieces to separate wires around the evaporator fan and they do rest on the coil, so maybe it's that stuff heating up?

Any help would be appreciated if any of you guys are still around! Thanks!

Also, have any of you had to deal with any kind of acetone smell coming from the fridge? I get a whiff sometimes when I walk by it. It isn't a refrigerant leak, so I'm not 100% sure what it is. My old man thinks it might be the compressor heating up old paint or glue, or possibly dust. There is also plumber's putty it seems holding two sheet metal pieces to separate wires around the evaporator fan and they do rest on the coil, so maybe it's that stuff heating up?

Any help would be appreciated if any of you guys are still around! Thanks!

Last edited:

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

Similar threads

- Replies

- 0

- Views

- 450

- Replies

- 13

- Views

- 1K

- Replies

- 1

- Views

- 412

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)