Update to the evaporator drip pan perforation repair....

First of all, for anyone who has water collecting inside your TDD-2, and it's more than 6-8 years old, you almost certainly have a perforated evaporator drip pan. The telltale sign, without disassembling everything, are small dots of rust on the bottom of the pan.

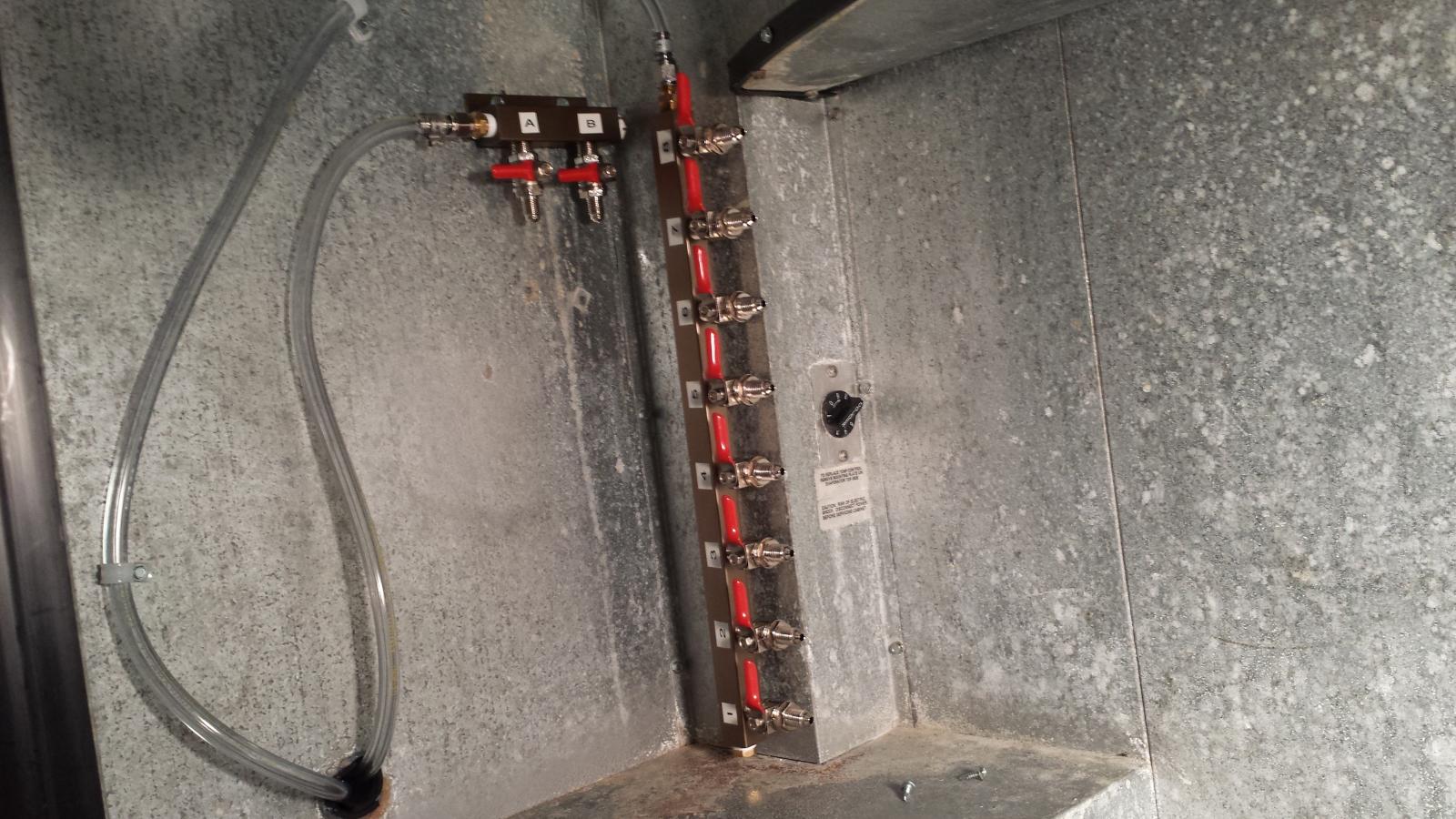

Your evaporator is located along the top of the back wall, and has a galvanized steel drip pan below it, which also houses the evaporator fan. You can see photos of mine, disassembled, earlier in this thread.

After cleaning that thing up, hitting it with some Loctite Rust Neutralizer, and some self etching primer, it became obvious to me that paint was in no way going to seal all those pinholes.

So I mixed up some five minute JB Weld and applied it. It sets pretty fast, which is good, because it took a number of passes to actually hit all the holes (they're hard to see without a light source behind them).

I sanded, and hit it with one more light coat of primer, and now I will topcoat with white epoxy paint. At this point, the thing is sealed, I'm just coating with epoxy just to insure longevity of the repair.

All the above sounds like a lot of work, but it only took sporadic effort over a weekend in between drying and cleaning out the evaporator - that's a story for another post...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)