SV_1, just curious but how did you attach the ground cable to the inside of the 2.5" couplers that have been welded together?

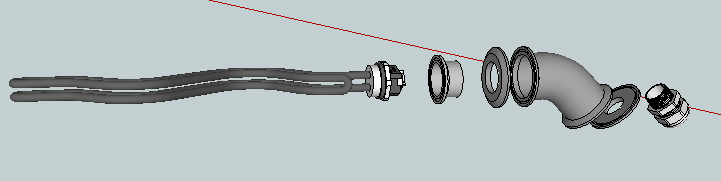

I'm not sure how he did his, but here's one way you could do it. This is mine:

SV_1, just curious but how did you attach the ground cable to the inside of the 2.5" couplers that have been welded together?

Nice shot Kevinik, very helpful. What did you use to drill and tap the caps, any problems there?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

From previous page.(btw you guys are overly anal with cleaning. Not a bad thing. At my winery we pressure wash our giant tanks with a heated pressure washer and no chemicals. Just hot water over 200 degrees. It'll kill all bacteria, yeast and spores. Never had a bacteria problem.

Kevin - I used the new micromark lathe I got for Christmas to cut the hole to 1.200"(I think) , but 1" NPS tap in stainless cuts a bit much, and requires more torque than the three jaw chuck could do without possibly warping the end cap, so started with a 1" NPT tap, then finished with a 1" NPS

I need a lathe...

Technically couldn't you use just the NPT tap and drill it all the way through? I was under the impression that the diameter of NPS was equal to NPT at it's widest point, aka the end of the taper.

You can get a nice South Bend or similar American iron for a few hundred bucks on Craigslist very easily. Look around for a few weeks or months to get an idea of what a good deal is. Get one that has some tooling and start playing around. Prices vary depending on condition, brand, and accessories, but you can get something totally adequate for this type of work $500 give or take a few hundred. If you need your money back you can easily resell for what you bought it for, but you will not want to part with it.

I think your equipment will be fine, you should not expect to be touching any part of the boil kettle when wort is over 140 degrees, and the materials used in construction can all handle well over 250 degrees without worry...