The fermenter has arrived. Ive spent a few hours dissembling everything, cleaning, inspecting, testing. have a few things to say about it, cause i know theres some interested eyes out there.

lets get the negatives out of the way first...

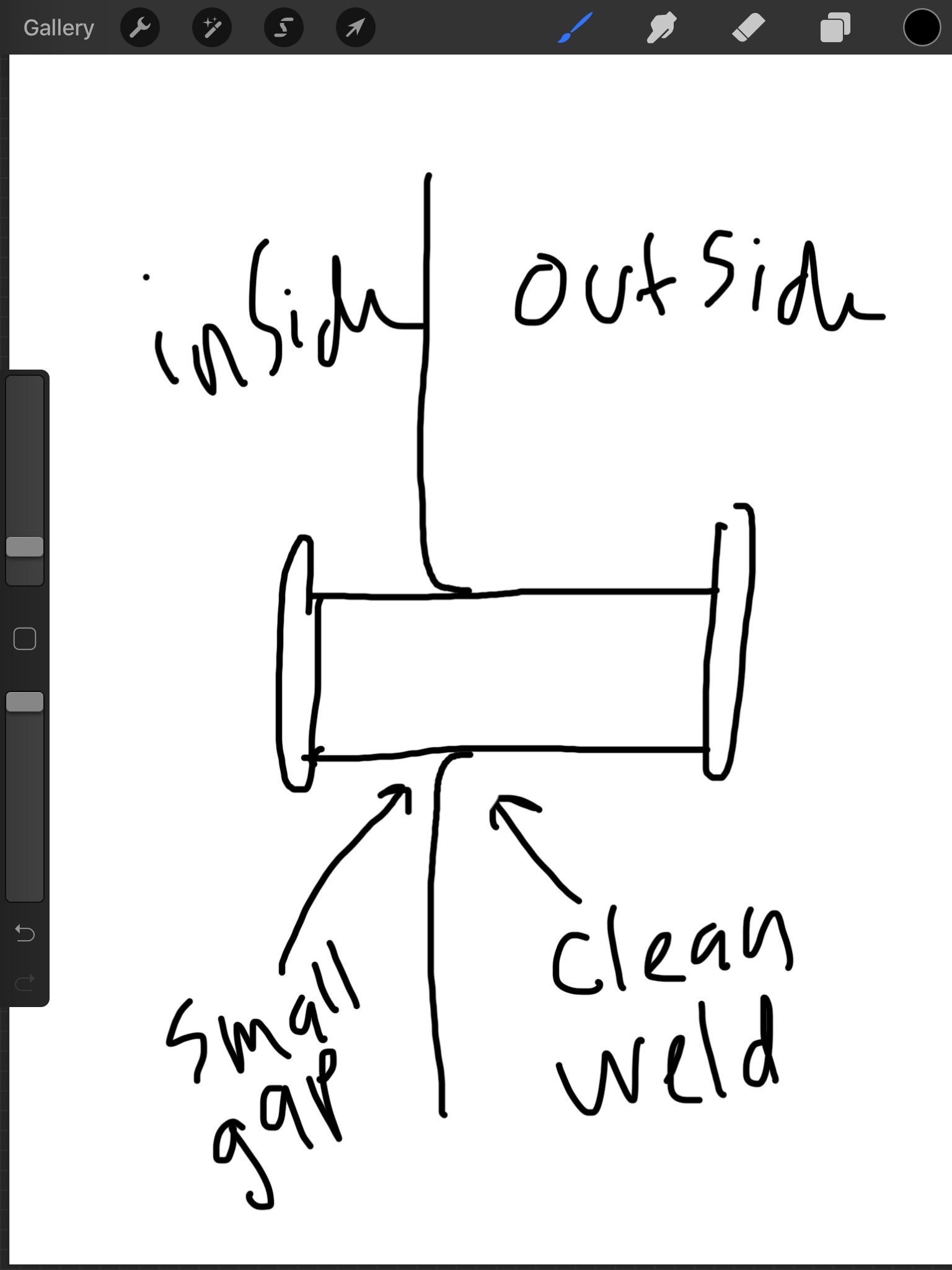

-The internal tri clamp fittings are not good. this is really the only big negative for me. Not sure how best to communicate how they executed it, but its only welded on the outside, so there is def a nasty crevasse on the inside that is darn near impossible to properly clean. Ive attached a photo of it. Im not sure what to do about it, I'm wondering if there is any kind of food grade silicone adhesive that might do the trick? or I could just break out a torch to sterilize it between brews. Any ideas? trying to avoid welding and polishing if i can.

-A bit of grease and soot here and there. They didnt clean it very well after manufacturing. not too big a deal, everything is easily broken down and cleaned.

- Both o-rings in the sample port were damaged. I noticed it when i took it apart to clean the soot and grease out of it. Not a big deal, new o rings are cheap and easy to get.

-The rotating racking arm, while very high quality, is not bent at the right angle. Its bent at 45 and i think closer to 90 would be better. I will have to bend it a bit more if I can.

-the cooling coil is a bit meh. there is a sloppy weld on it and one of the tri clamp fittings is a bit crooked. Ive presure tested it while hooked up inside the fermenter and all is good, its probablhy more cosmetic thatn anything.

-My name was spelled wrong on the package (i know i provided them my name correctly spelled) thank god they didn't mess up my address..

the good:

-Everything that was promised was there.

-it was shipped in a nice custom built wood box. no damage from shipping.

-in general, the build quality is very good. the welds look good and sanitary (with the exception if the cooling coil...), the stainless is thick, every single part is highly polished, the valves and clamps are very high quality.

-the lid seal and clamp look really good. I have no doubt it will hold pressure, at a minimum enough to pressure transfer.

-everything works, no leaks, I'm happy.

Now, to sort out the strange cooling coil connections...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)