toothandnailbrew

Member

- Joined

- May 31, 2021

- Messages

- 10

- Reaction score

- 12

Hopefully this is the right section or an admin moves this. First about me and the arc of my brewing life so far, then I will post the build.

I cut my teeth on homebrewtalk, obsessive novice to competitive aspirant to dreaming entrepreneur. Well the day came and I started my first brewery. A 15bbl Combitank I posted here at some point. That first one, nearly ten years ago. I made a lot of mistakes, learned a lot of lessons, read a lot of books. I was 21 when I built it.

I left due to boiler issues and being too young to push around ownership and investors to get the boiler fixed.

I worked as a beer manager at a local liquor store a few months, then at a craft centric distributor a couple years, Savannah dist. To this day, their portfolio blows my mind. What great experience. But I am no salesman, I am a brewer so it didn't work out. Technical knowledge is meaningless in a distro setting. I had a stint at untappd which I hated and left quickly. Then the day came for my second brewery. I discovered MBAA which I cannot recommend enough. My second brewery? Shes still churning out great beer, about 6000bbl a year these days, mostly my base beers.

I left there a few years ago due to distaste for the owners style, lots of smoothie and pastry, none of my work speaking for itself. Won a couple US beer open golds and the brewery got a cover on Beer Connoisseur magazine.

I got headhunted for my skillset in lager and went international. I built a Caribbean brewery, 15bbl 3 vessel manual with 21 30bbl fvs and a bottling line. The logistics of the operation were a nightmare and finding even homebrewers for assistants wasn't a thing there. A solitary challenge of self distribution, account management, production, all of it. I made great friends out there, true Caribbean and euros alike.

Then covid hit. The island was 90% tourism.

I was discouraged by the output and didn't see a future for myself there. So I left back for the states without a real plan.

Then I realized I love gear more than pandering. So I took a job with Alpha Brewing Ops, which I still work for. I build and commission canning lines primarily. I am glad to be learning electrical skills (which are still SO WEAK compared to the guys in the electric forum) I like it so far but have disconnected myself from the liquid. So in a sort of training montage I am honing my recipes.

I love sours and Flanders red/gueze is something I never got to master, even with a 180 oak barrels in my program, I never liked one. I have a long way to go still, and still plenty to learn. I am excited to get back to brewing what I want without concern for profit or marketability. Maybe one day I'll do another, but for now I need to find truth again.

There are none more enthusiastic and well read than the members of homebrewtalk. Doing and teaching situation sometimes. I'll post as I go build wise. I forgot how to post photos and such embedded in text. I'll edit as I get it. For now heres my garage. A 2vessel half bbl electric Biab of sorts in the works. Its kind of a scrap build, brewers aren't rich enough for triclamps on their own, but builders? TBD. Im waiting on parts which come Monday but I'm in Des Moines comissioning a canning line all week, so friday the build really begins.

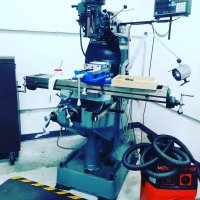

Here is also a photo of about 25% of the shop I currently work in. I'd love to talk shop with anyone willing.

I cut my teeth on homebrewtalk, obsessive novice to competitive aspirant to dreaming entrepreneur. Well the day came and I started my first brewery. A 15bbl Combitank I posted here at some point. That first one, nearly ten years ago. I made a lot of mistakes, learned a lot of lessons, read a lot of books. I was 21 when I built it.

I left due to boiler issues and being too young to push around ownership and investors to get the boiler fixed.

I worked as a beer manager at a local liquor store a few months, then at a craft centric distributor a couple years, Savannah dist. To this day, their portfolio blows my mind. What great experience. But I am no salesman, I am a brewer so it didn't work out. Technical knowledge is meaningless in a distro setting. I had a stint at untappd which I hated and left quickly. Then the day came for my second brewery. I discovered MBAA which I cannot recommend enough. My second brewery? Shes still churning out great beer, about 6000bbl a year these days, mostly my base beers.

I left there a few years ago due to distaste for the owners style, lots of smoothie and pastry, none of my work speaking for itself. Won a couple US beer open golds and the brewery got a cover on Beer Connoisseur magazine.

I got headhunted for my skillset in lager and went international. I built a Caribbean brewery, 15bbl 3 vessel manual with 21 30bbl fvs and a bottling line. The logistics of the operation were a nightmare and finding even homebrewers for assistants wasn't a thing there. A solitary challenge of self distribution, account management, production, all of it. I made great friends out there, true Caribbean and euros alike.

Then covid hit. The island was 90% tourism.

I was discouraged by the output and didn't see a future for myself there. So I left back for the states without a real plan.

Then I realized I love gear more than pandering. So I took a job with Alpha Brewing Ops, which I still work for. I build and commission canning lines primarily. I am glad to be learning electrical skills (which are still SO WEAK compared to the guys in the electric forum) I like it so far but have disconnected myself from the liquid. So in a sort of training montage I am honing my recipes.

I love sours and Flanders red/gueze is something I never got to master, even with a 180 oak barrels in my program, I never liked one. I have a long way to go still, and still plenty to learn. I am excited to get back to brewing what I want without concern for profit or marketability. Maybe one day I'll do another, but for now I need to find truth again.

There are none more enthusiastic and well read than the members of homebrewtalk. Doing and teaching situation sometimes. I'll post as I go build wise. I forgot how to post photos and such embedded in text. I'll edit as I get it. For now heres my garage. A 2vessel half bbl electric Biab of sorts in the works. Its kind of a scrap build, brewers aren't rich enough for triclamps on their own, but builders? TBD. Im waiting on parts which come Monday but I'm in Des Moines comissioning a canning line all week, so friday the build really begins.

Here is also a photo of about 25% of the shop I currently work in. I'd love to talk shop with anyone willing.

Attachments

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)