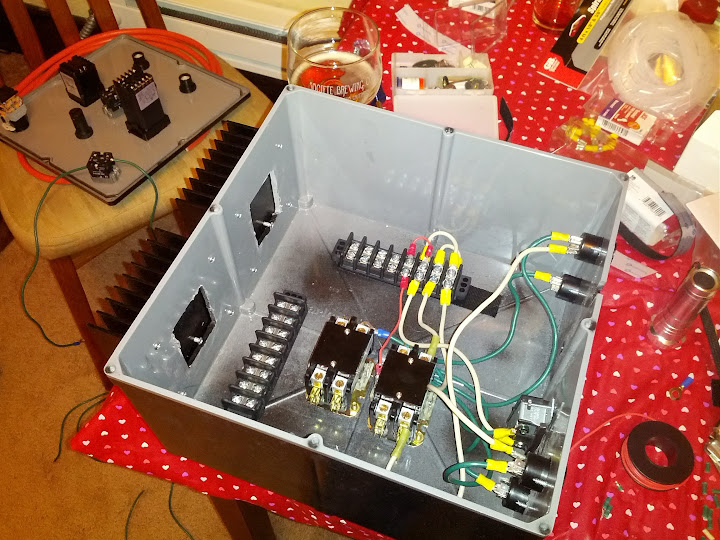

You did good and are right on the money with your understanding of the diagram.Isnt the switch that PJ is showing a 3 way switch. So i could switch it between the timer/off/PID? If its like that it would be great. However, if im mistaken than i definitely want two switches.

P-J

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)