I have option for 0.5mm wall thickness and 1mm thickness. I would assume that 0.5mm will have better thermal heat transfer and easier to DIY as its more malleable? My doubt is whether its enough or you need atleast 1mm?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thickness of the copper tube wall(not cross section diameter) to be used as chiller.

- Thread starter Luxy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Thinner is better for heat transfer, and is easier to bend. Type M is even better, since it is very thin (.28) but still plenty thick, but if .5 is the thinnest you can get, then go for that. It will be a little hard to bend. I'd look for Type M if at all possible.

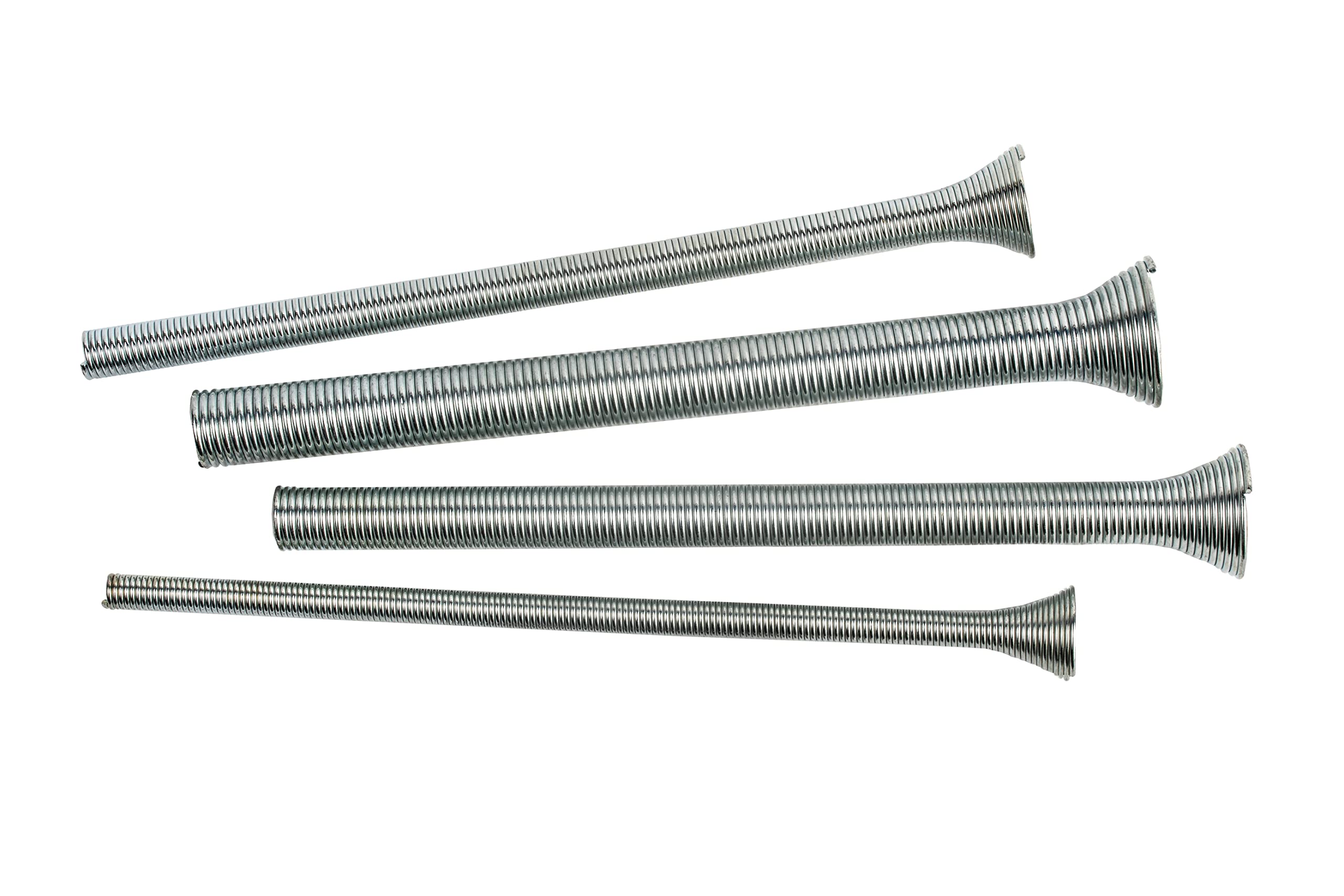

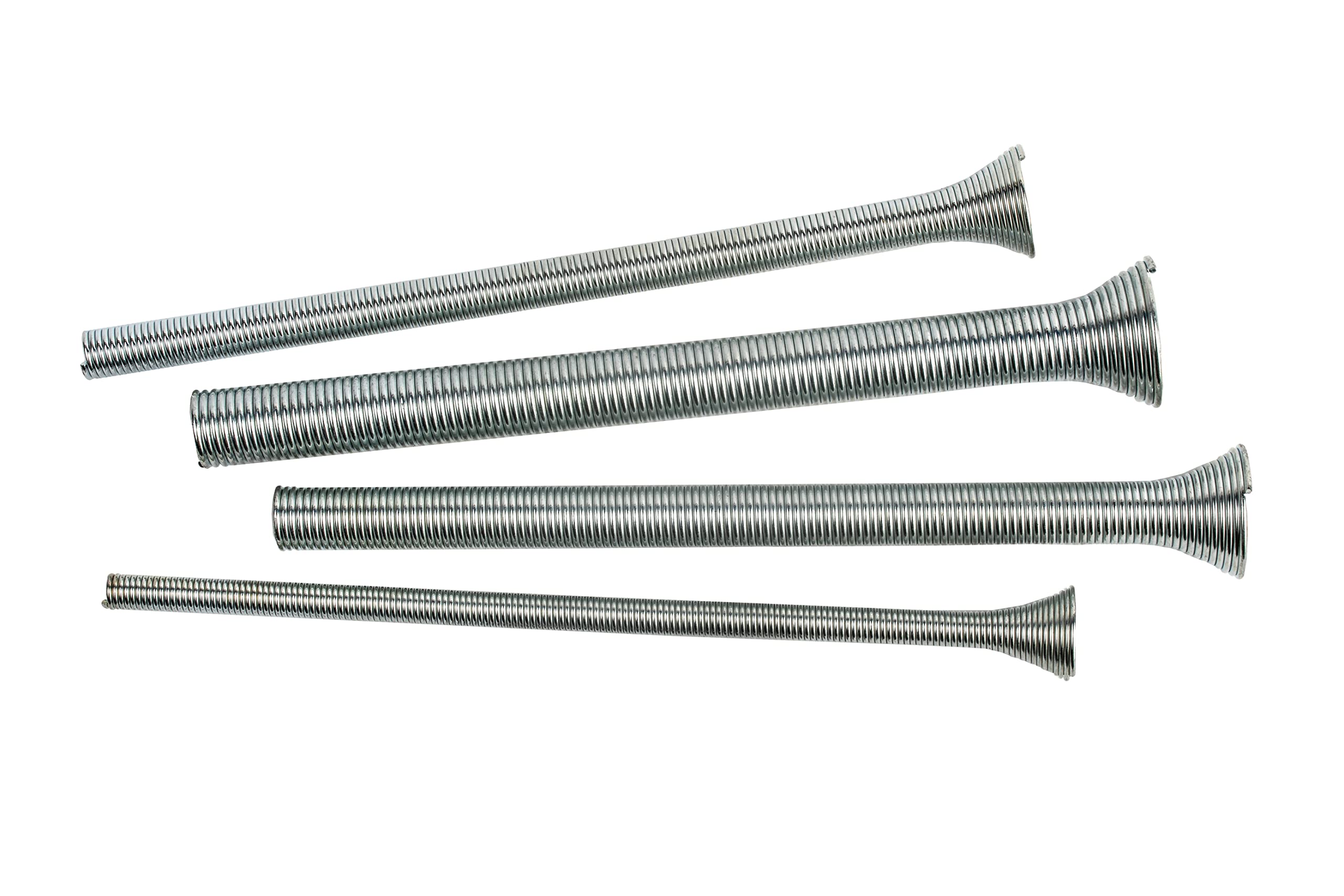

Get a tubing bender to avoid kinks.

Hi @lumpher , sorry for the late reply. I went on to do some search around several sites for the type M copper tube and found their thinnest to be 0.025inch which equates to 0.635mm. I am not sure if I am getting the right info so I will have it paste here. If the info is correct then I will be good with 0.5mm one right? I do however found 9mm diameter tube with 0.25mm wall thickness which lead me to making a choice between 16mm with 0.5mm wall or 9mm with 0.25mm wall. Would the 9mm cross section be any good if used to construct counter-flow chiller? @MaxStout Thanks for the tips =)

Similar threads

- Replies

- 8

- Views

- 3K