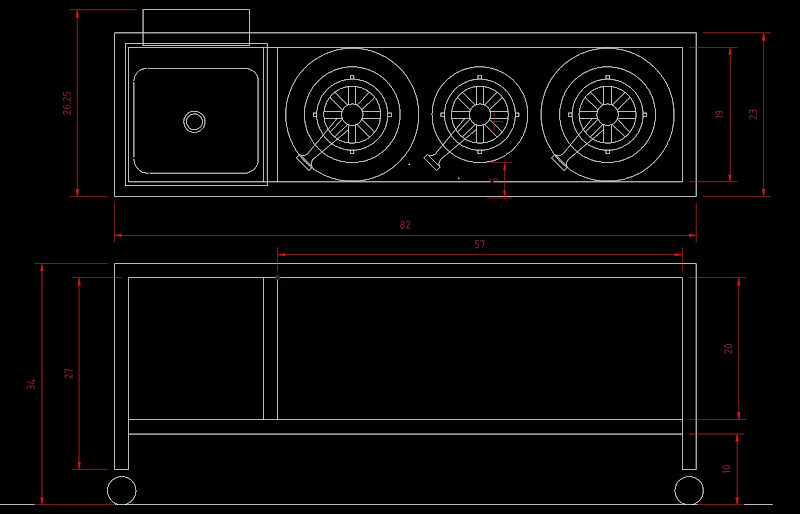

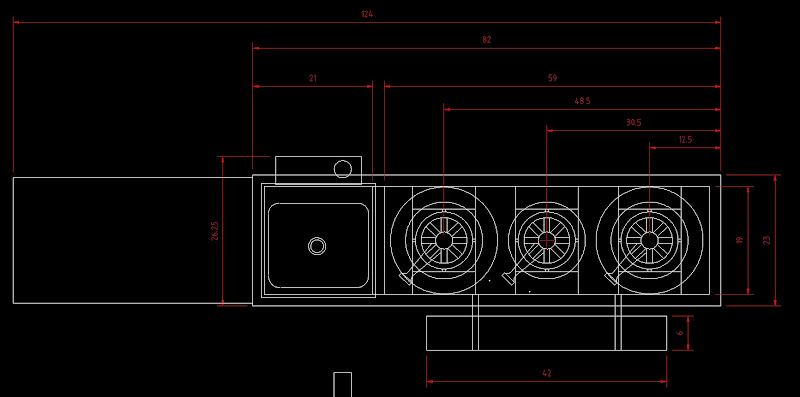

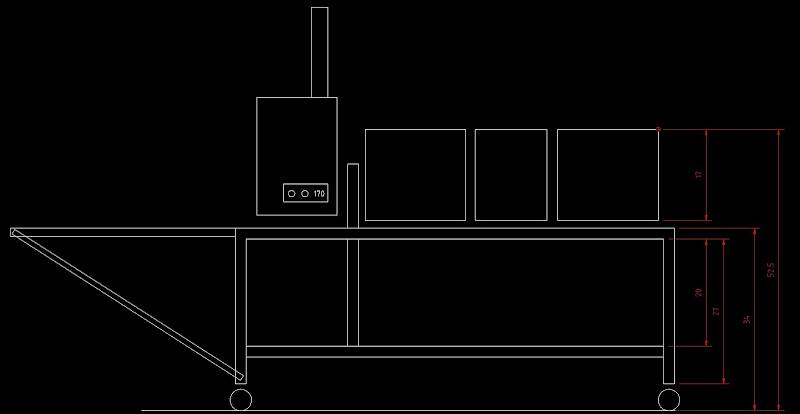

I'm building a brewstand. I'm naming it Zeus.

I had a brewstand 10 years ago using various keggles and coolers but sold it. I've been meaning to get back into brewing ever since. This fall I'm taking the plunge and building a brewstand to get going again.

Zeus is a bit off the wall. I made a list of everything that made my past brewing experiences less than perfectly enjoyable and tried to design Zeus to address those issues.

Here is what I am planning.

- stainless steel stand on locking casters

- 2x 11 gallon SS boil kettles

- an 11 or 20.5 gallon direct fired SS mash tun on a tippy for easy clean out

- each vessel has its own March pump

- each vessel has its own temperature control loop

- an on demand hot water heater built into the stand to supply mash in, sparge and cleaning water

- a stainless steel water/wort manifold with manual valves and cam lock fittings

- 30(?) plate chiller

- the manifold breaks down into pieces for easy cleaning in a regular sink

- natural gas burners using gas control valves to automate burner firing

- a SS sink built into the stand with a pump for pumping out waste water

- a fold out SS work leaf

- storage on the lower level of the brewstand

- compressed air input on the stand to blow out all the lines when I am done brewing. I winterize our RV this way and it works well.

- controlled by BrewPi via a browser on a remote computer (Tablet, laptop, etc.)

I've been amassing parts for Zeus for nearly a year.

I'll either be brewing outside or in my heated garage. I've never brewed in the summer, so mostly I'll be brewing in the garage.

I have no running water in my garage thus the need for the hot water heater and sink on the brewstand. No more continuously running into the house to wash things !

I'll be brewing 5, 8 and 15 gallon batches, all kegged. No bottling.

I went with 2 boil kettles for versatility. I'd rather brew more smaller batches than fewer big batches. I'm hoping that with enough automation that I can brew 2 batches almost simultaneously. I'm building the stand large enough to size up one of the boil kettles to 20.5 gallons.

Zeus will be stored outside when not being used.

I have just about all the parts and pieces to assemble Zeus. I'll post pictures as I do.

I had a brewstand 10 years ago using various keggles and coolers but sold it. I've been meaning to get back into brewing ever since. This fall I'm taking the plunge and building a brewstand to get going again.

Zeus is a bit off the wall. I made a list of everything that made my past brewing experiences less than perfectly enjoyable and tried to design Zeus to address those issues.

Here is what I am planning.

- stainless steel stand on locking casters

- 2x 11 gallon SS boil kettles

- an 11 or 20.5 gallon direct fired SS mash tun on a tippy for easy clean out

- each vessel has its own March pump

- each vessel has its own temperature control loop

- an on demand hot water heater built into the stand to supply mash in, sparge and cleaning water

- a stainless steel water/wort manifold with manual valves and cam lock fittings

- 30(?) plate chiller

- the manifold breaks down into pieces for easy cleaning in a regular sink

- natural gas burners using gas control valves to automate burner firing

- a SS sink built into the stand with a pump for pumping out waste water

- a fold out SS work leaf

- storage on the lower level of the brewstand

- compressed air input on the stand to blow out all the lines when I am done brewing. I winterize our RV this way and it works well.

- controlled by BrewPi via a browser on a remote computer (Tablet, laptop, etc.)

I've been amassing parts for Zeus for nearly a year.

I'll either be brewing outside or in my heated garage. I've never brewed in the summer, so mostly I'll be brewing in the garage.

I have no running water in my garage thus the need for the hot water heater and sink on the brewstand. No more continuously running into the house to wash things !

I'll be brewing 5, 8 and 15 gallon batches, all kegged. No bottling.

I went with 2 boil kettles for versatility. I'd rather brew more smaller batches than fewer big batches. I'm hoping that with enough automation that I can brew 2 batches almost simultaneously. I'm building the stand large enough to size up one of the boil kettles to 20.5 gallons.

Zeus will be stored outside when not being used.

I have just about all the parts and pieces to assemble Zeus. I'll post pictures as I do.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)