copper2hopper

Well-Known Member

Morning everyone!, Sorry to start a new thread on this topic but I didn't want to resurrect an old one from the ones I have extensively read through. From what I gathered is that people have their personal preferences on where they place their probe that is connected to the external thermostat ranging from dangling in the air in the chamber, in a thermowell, insulated to the side of the carboy...etc. I am anxiously awaiting for the arrival of my Johnson A419 controller next week to connect to my brand new 7 cubic foot Criterion chest freezer I just bought from Menards this week. Finally!.....fermentation temperature control!!!...super excited.

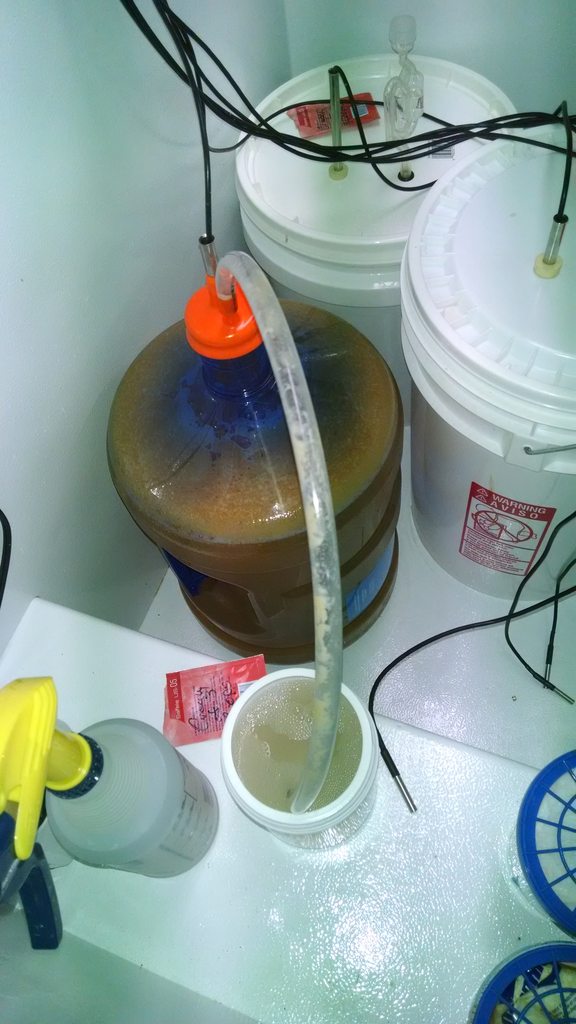

I think I have decided to go with the method of having the Johnson A419 probe stuck up against the exterior fermenter wall protected by some extra reflectix I have available. And then to have a separate digital thermometer probe monitoring the ambient chamber air so I know how hard or not hard the chest freezer is working to keep the ambient air at "xx" degrees while the Johnson A419 controller temperature prob is reading "xx" degrees. Obviously I'm trying to keep that Johnson A419 controller temperature prob to maintain a constant temperature at the recommended temperature for that particular style of beer paired with whatever particular type of yeast I'm using.

I guess my question is, through the other threads I have read, it seemed like a vast majority of people here have the probes switched the other way around and not the way I have listed above? It seemed backwards to me me and that's why I feel like doing it my way listed above would make more sense. Do any of you have it as I have listed above? Pros vs Cons??? etc... Looking for some guidance being that it will be my first time doing this. Thank you in advance

I think I have decided to go with the method of having the Johnson A419 probe stuck up against the exterior fermenter wall protected by some extra reflectix I have available. And then to have a separate digital thermometer probe monitoring the ambient chamber air so I know how hard or not hard the chest freezer is working to keep the ambient air at "xx" degrees while the Johnson A419 controller temperature prob is reading "xx" degrees. Obviously I'm trying to keep that Johnson A419 controller temperature prob to maintain a constant temperature at the recommended temperature for that particular style of beer paired with whatever particular type of yeast I'm using.

I guess my question is, through the other threads I have read, it seemed like a vast majority of people here have the probes switched the other way around and not the way I have listed above? It seemed backwards to me me and that's why I feel like doing it my way listed above would make more sense. Do any of you have it as I have listed above? Pros vs Cons??? etc... Looking for some guidance being that it will be my first time doing this. Thank you in advance

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)