"Line resistance matters", and forty feet of 4mm ID tubing is going to have hella high resistance

Go parallel...

Cheers!

Go parallel...

Cheers!

"Line resistance matters", and forty feet of 4mm ID tubing is going to have hella high resistance

Go parallel...

Cheers!

"Did I stutter?"

(Lol! That's a line from The Breakfast Club and I've been waiting forever to use it)

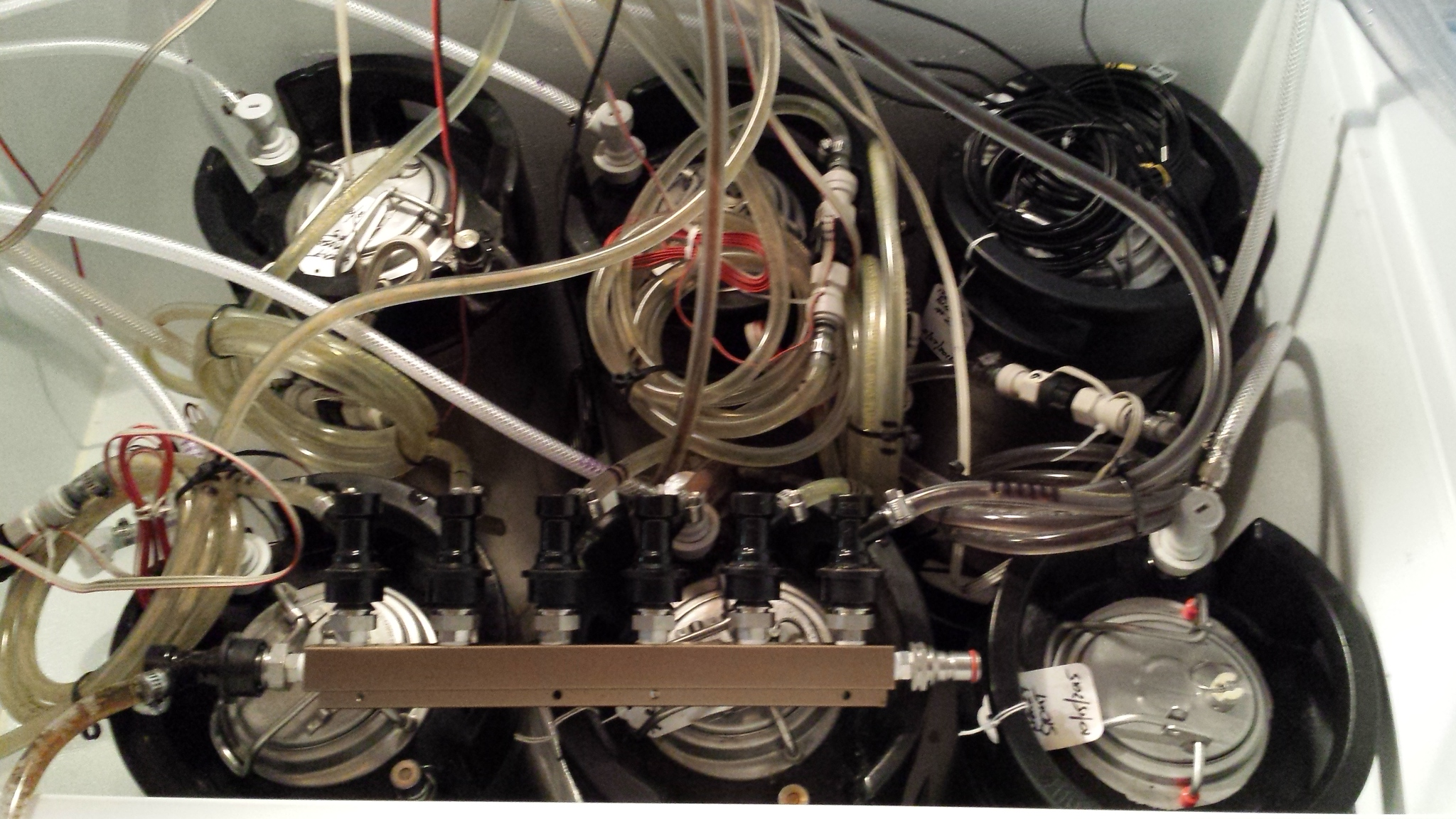

But, yes, parallel: I run a 6 tap t-tower and even back in the "12 feet of 3/16" ID tubing per tap" days trying to recirculate cleaner through all of that tubing was never going to work in a serial fashion. So I had Matt's crew at chicompany.net cook up a "sanitizing manifold" with enough ball lock posts to fit all of my QDs plus an input liquid post and a gas input post. Looks like this (excuse the following horrible pictures, I think I have better ones but damned if I can find them right now):

View attachment 730179

In use it looks like this:

View attachment 730181

Then I used a bunch of PVC fittings to cobble up a return manifold that looks like this:

View attachment 730180

With all that in place I use a pair of 5 gallon buckets with a decent pond pump to rinse the lines out, then recirculate BLC or LLC (whichever I have in stock) for 20 minutes or so, then rinse it all back out, then I can plug a gas QD on the same input manifold and blow out any residual liquid if desired. Cleans everything from QDs through flow meters through beer lines through faucets...

Cheers!

Makes me wonder why they don't rate pumps by their push power VS just gpm.

Actually, they do, it can just be hard to find. They rate them with "head" or "lift", with a distance in feet (or meters). You can then find info on internet on equivalent head/lift different lines give you per linear foot.