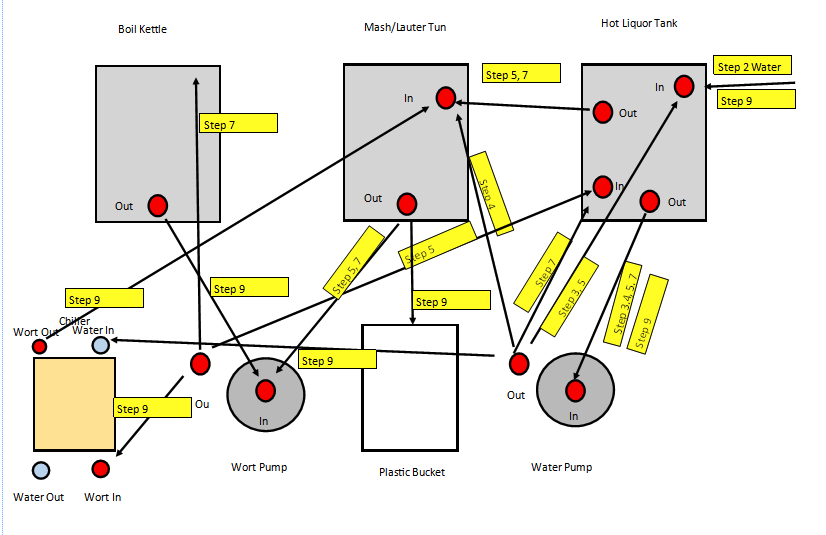

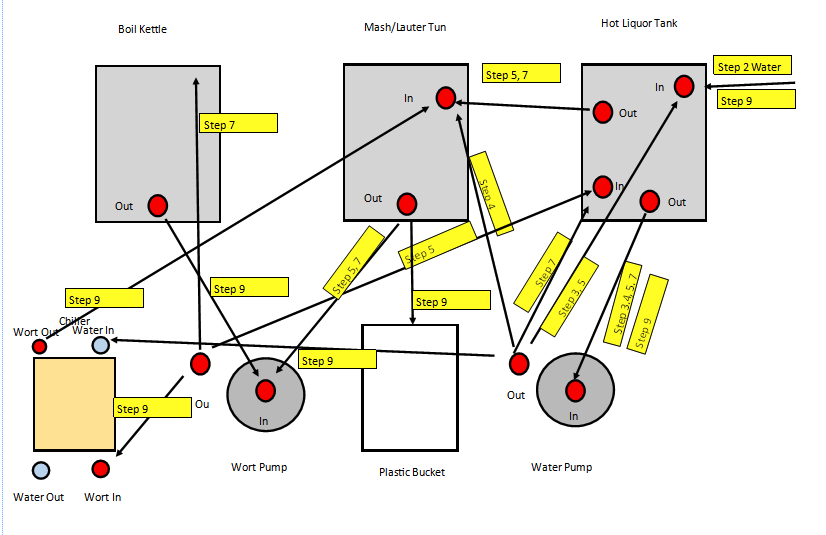

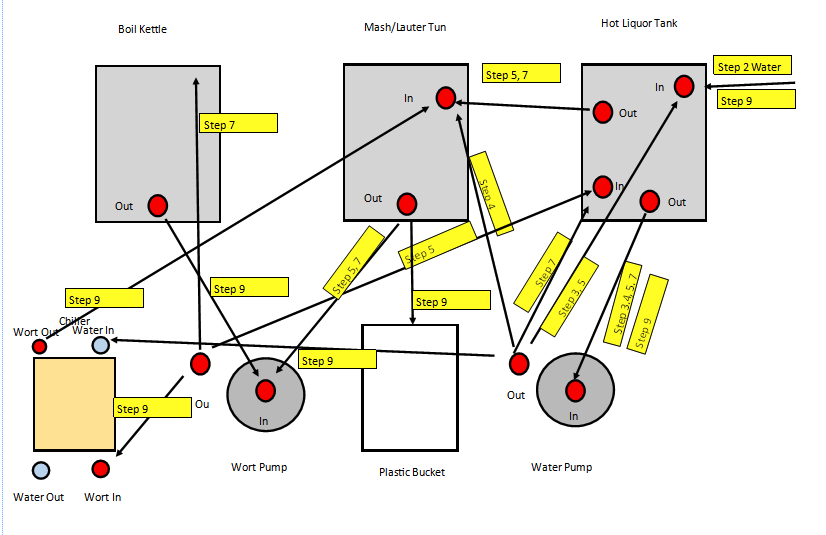

My setup follows. Any recommendations, suggestions, etc on omitting swapping tubes?

Have you thought about building a manifold with. An inlet and multiple outlets with a ball valve on each! It's what I do and love it. Just a thought. That does look like a PITA to deal with. Maybe add a grant to simply ???

Cheers

Jay

Not really sure without seeing your actual process. Likely you could optimize your process a tad to make things simpler. But like I said without actually having a full understanding of that process I couldn't say 100%. Just remember for every time you swap hose to the input side of the pump to the outfeed of the pump you'll need a ball valve. Personally I can't imagine needing more than 1 in and out per kettle per pump. So 3 in and 3 out per pump. 12 valves? Then optimize your process from there. Do you use both pumps for every kettle? If not at that spot you eliminate a ball valve.@Jaybird any images or info for the manifold? I was thinking the same. Problems that come to mind. Where to attach the manifold (I have a SS brew table holding all the kettles). Also, I use QD on the ends of the hoses.

@RufusBrewer possible to see photos or links to items mentioned in your post? Thanks.