I had a non stc-1000 temperature controller fail on my fermentation chamber today and would like to order a replacement stc-1000+ pre-flashed with this firmware if possible. I noticed that Black Box sells them, but it says he's on vacation until Thursday and orders are turned off until then. Does anyone know if anyone else sells them pre-flashed? I need to get it replaced as soon as possible and would rather not have to order a non-flashed controller. Thanks for the help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stc-1000+

- Thread starter alphaomega

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

smithabusa

Well-Known Member

I have a couple I just bought from Will, I flashed 1.06 on them, can drop one in the mail tomorrow for you if that helps get you by.

Greg

Greg

Singletrack

Because it's judgement that defeats us.

I finally had some time to work on my datalogger project for the STC.

It is far from finished, but this will be sweet...

Cheers!

//mats

I'm having trouble building this based on your photos.

I'm hoping you didn't intend for us to start the build yet. I just wanted to express my interest in this new development and encourage further progress and updates. Thank you!

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

I'm having trouble building this based on your photos.

I'm hoping you didn't intend for us to start the build yet. I just wanted to express my interest in this new development and encourage further progress and updates. Thank you!

Hey!

Thanks a lot! It's nice to know it is of interest to someone

Yes, I know. It is work in progress... I've started a github project, but it is still mainly for my own use. I probably won't document the heck out of this, as it is kind of 'power user' stuff, but absolutely well enough that anyone with some 'maker skills' will have no problem wrapping their heads around it.

The sketch I'm developing will be pretty much the stuff I want, but if you have other stuff in mind, it should be a good starting point.

I'll try to push some code and update some documentation in the next few hours if you're eager, but it is still early

Cheers!

orangehero

Well-Known Member

I have some comments and questions on v.1.06:

When in the soft power off state, is the display supposed to show OFF continously? It would be nice to have it show the temperature as well, say as an alternate display after pressing "SET", if you're just letting the temperature free rise or you want to know what temperature the beer is conditioning at just at ambient temperature.

When turned back on from the soft power off state the temp reading seems to default to Temp Sensor 2 and shows some erratic values even when it is disabled.

Also when turned back on from soft power off it seems the temp reading is reset, and it takes some time for the display to stabilize. Not sure what is going on here, if I'm not mistaken this didn't occur in previous versions and showed the correct temperature immediately as long as the temp sensor itself was stable.

When in the soft power off state, is the display supposed to show OFF continously? It would be nice to have it show the temperature as well, say as an alternate display after pressing "SET", if you're just letting the temperature free rise or you want to know what temperature the beer is conditioning at just at ambient temperature.

When turned back on from the soft power off state the temp reading seems to default to Temp Sensor 2 and shows some erratic values even when it is disabled.

Also when turned back on from soft power off it seems the temp reading is reset, and it takes some time for the display to stabilize. Not sure what is going on here, if I'm not mistaken this didn't occur in previous versions and showed the correct temperature immediately as long as the temp sensor itself was stable.

Singletrack

Because it's judgement that defeats us.

Hey!

Thanks a lot! It's nice to know it is of interest to someone

Yes, I know. It is work in progress... I've started a github project, but it is still mainly for my own use. I probably won't document the heck out of this, as it is kind of 'power user' stuff, but absolutely well enough that anyone with some 'maker skills' will have no problem wrapping their heads around it.

The sketch I'm developing will be pretty much the stuff I want, but if you have other stuff in mind, it should be a good starting point.

I'll try to push some code and update some documentation in the next few hours if you're eager, but it is still early

Cheers!

Mats, youre the hardest working man in brewtronics! No, instead of pushing code and updating documentation in the next few hours, I suggest you take a break and have a cold one. (Then right back to work!

I certainly wasnt trying to push you. I just wanted to show enthusiasm for this project, since that seems to be the only payment you request/receive.

In my case, logging would be great because I am away from my brewery all week for work. For all I know, the STC takes a 5-day snooze as soon as I leave. With my STC+, at least I can vary temperatures while I am away. (Thank you!) Now I would like to know how fast I can ramp without crazy heat-cool oscillations.

[Yeah, I know, with a BrewPi I could blah, blah, blah. Wrong thread, people. Sorry BrewPioneers, must be the saison talking.]

My first step is to install and use the second temperature probe to control temperature offset. Brilliant. Im not sure I understand how to install the probe from reading the operating manual, but maybe I just need to read through some of the old posts. I was disappointed to find that my stash of resistors are all 5% tolerance, and I should use 1%. Oh well, someone will sell them to me.

So, you see I am not quite ready for your logging modification, but Im looking forward to it nonetheless.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Thank you very much for your feedback!I have some comments and questions on v.1.06:

When in the soft power off state, is the display supposed to show OFF continously? It would be nice to have it show the temperature as well, say as an alternate display after pressing "SET", if you're just letting the temperature free rise or you want to know what temperature the beer is conditioning at just at ambient temperature.

Yes it is, as previously it was blank, which led people to believe the unit was broken, when they plugged it in after some time when it was only in 'off mode'.

I'm not crazy about this idea, but I understand your reasoning. I'm not sure I even can do this as the timer responsible for temp and temp control is shut off during power down. I'll make a note and think about this for a bit.

Yes. I've noticed too. This due to pwr btn being used for more than one thing. I'll see if there is something I can do to prevent the switch. Switching temp is 'legal' though even if Pb2=0. The setting only says not to use probe 2 in regulation algorithm.orangehero said:When turned back on from the soft power off state the temp reading seems to default to Temp Sensor 2 and shows some erratic values even when it is disabled.

orangehero said:Also when turned back on from soft power off it seems the temp reading is reset, and it takes some time for the display to stabilize. Not sure what is going on here, if I'm not mistaken this didn't occur in previous versions and showed the correct temperature immediately as long as the temp sensor itself was stable.

Yes. But with probe 2 I need to init the the filter statically as taking readings from both made init too complex. I don't think this is a big thing as you still have the 1 minute grace period on start.

Mats, youre the hardest working man in brewtronics! No, instead of pushing code and updating documentation in the next few hours, I suggest you take a break and have a cold one. (Then right back to work!)

I certainly wasnt trying to push you. I just wanted to show enthusiasm for this project, since that seems to be the only payment you request/receive.

In my case, logging would be great because I am away from my brewery all week for work. For all I know, the STC takes a 5-day snooze as soon as I leave. With my STC+, at least I can vary temperatures while I am away. (Thank you!) Now I would like to know how fast I can ramp without crazy heat-cool oscillations.

[Yeah, I know, with a BrewPi I could blah, blah, blah. Wrong thread, people. Sorry BrewPioneers, must be the saison talking.]

My first step is to install and use the second temperature probe to control temperature offset. Brilliant. Im not sure I understand how to install the probe from reading the operating manual, but maybe I just need to read through some of the old posts. I was disappointed to find that my stash of resistors are all 5% tolerance, and I should use 1%. Oh well, someone will sell them to me.

So, you see I am not quite ready for your logging modification, but Im looking forward to it nonetheless.

No worries, it is good to have some incentive.

5% might well work. You could try measuring, and see if you find a resistor that matches the one on the stc.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Maybe a tip..?

Is there available space, in a profile, to set DryHop1 and DryHop2 as parameter. Example dH1=120 dH2=168 and the display flashes dH1 when the time is reached?

Thanks for the suggestion! But I think unless you could incorporate an automatic hop dropper of some sort, this would be of limited use (and also use up valuable code space). I would think setting an appointment in your calendar (in your phone or filofax or whatever you like to use), would be more useful. I would think more often than not, the ferm fridge will not be in direct line of sight when this happens anyway. Using the buzzer would make more sense, but even so, I think this just adds unnecessary complexity.

Hi,

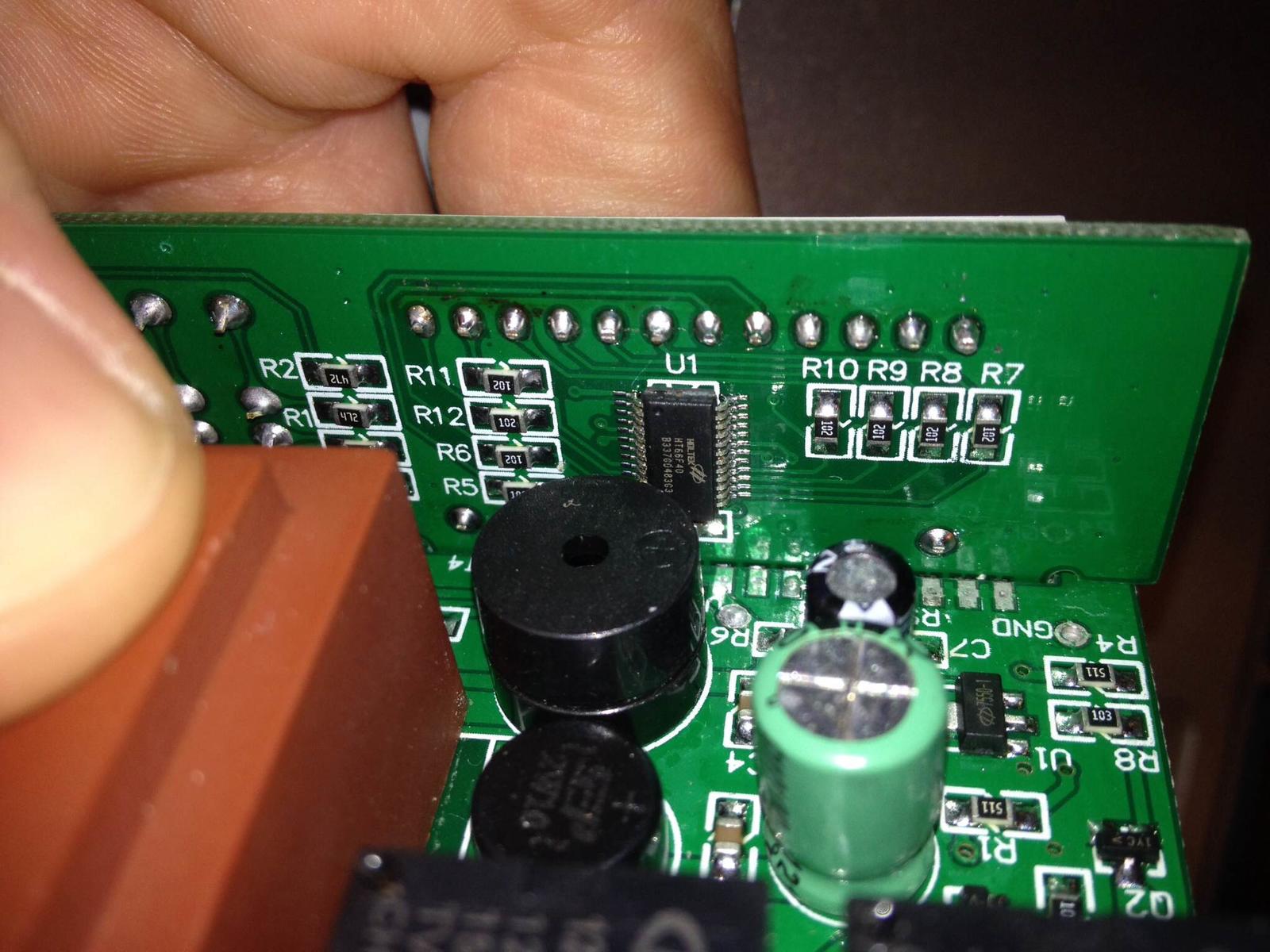

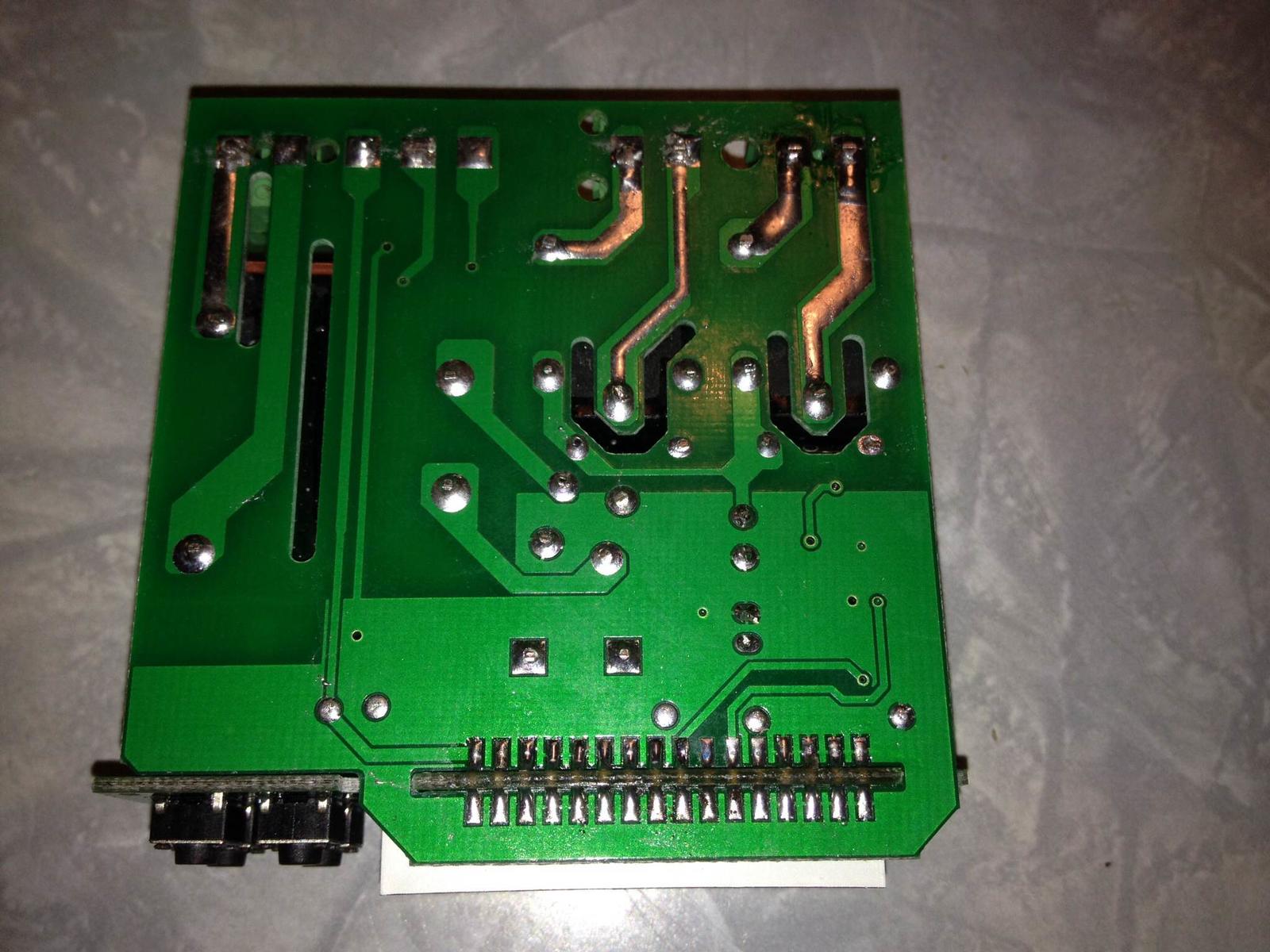

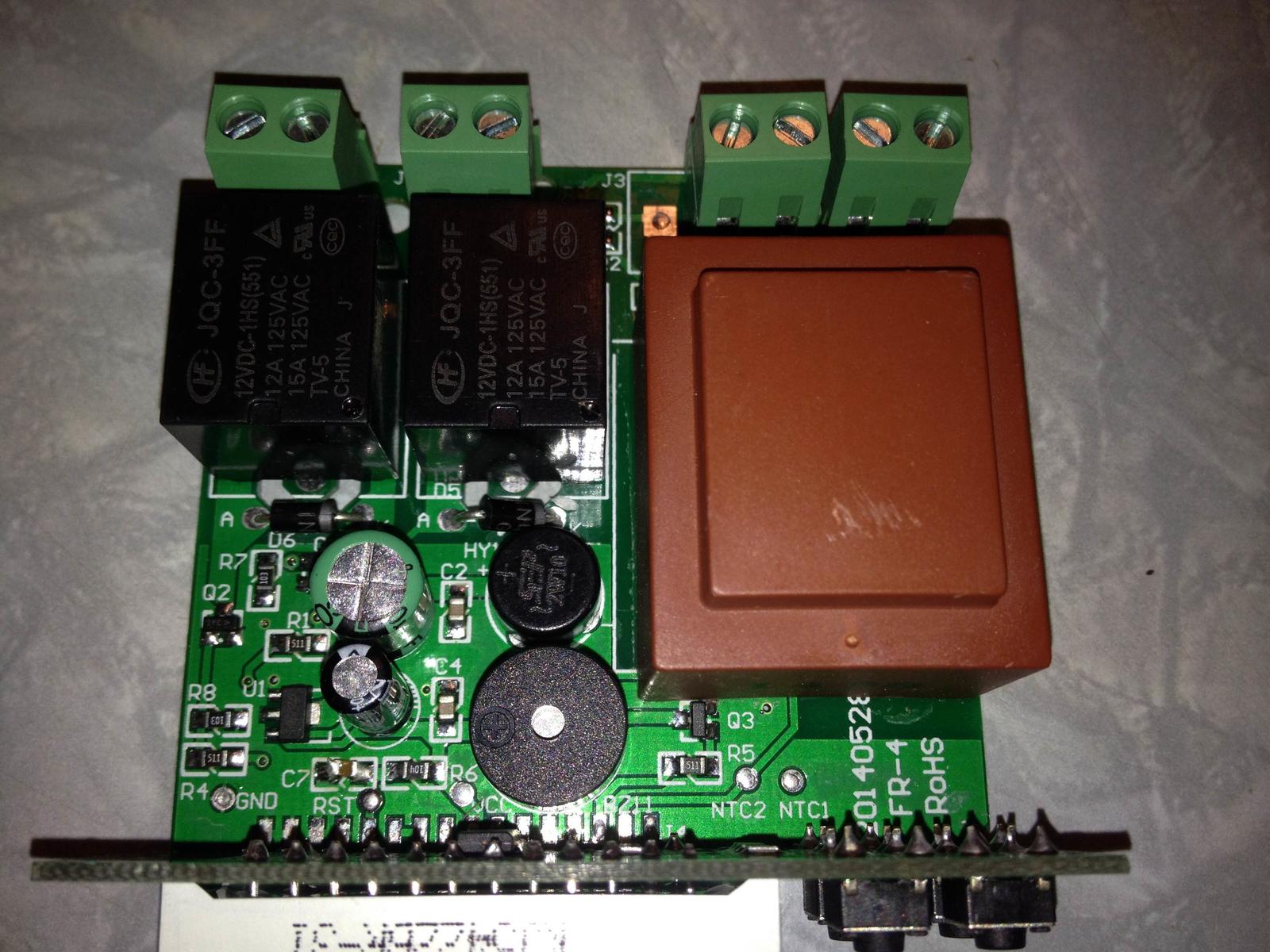

just received the wrong version (from eBay seller mixtea). It is labelled 20140528 FR-4, micro controller is HOLTEK HT66F40, see attached photos.

Is this version compatible in any way?

Cheers.

No, sorry it is not compatible with STC-1000+. It'll still function as a regular STC-1000 though which is not all that bad. They can be useful for a bunch of stuff. Maintaining HLT temp during brewing for example, or just as a backup.

Bigdaddyale

Well-Known Member

I just received 2 more units today.total of 4 with ver 1.0I was successful purchasing 2 STC-1000 that were v1.0 from this Amazon seller on August 23rd (Seller is "City Digital" in case it doesn't carry through on the URL):

http://www.amazon.com/dp/B008KVCPH2/?tag=skimlinks_replacement-20

I don't know if it'll continue to work, but it was worth the risk for my needs, and it paid off.

Last edited by a moderator:

wilconrad

Well-Known Member

Hi,

just received the wrong version (from eBay seller mixtea). It is labelled 20140528 FR-4, micro controller is HOLTEK HT66F40, see attached photos.

Is this version compatible in any way?

Cheers.

Interesting. This is the first "unflashable" version I've seen with the power & sensor terminals close together. Looks like that check is no longer legit. Crazy how many versions of this thing we've come across so far!

Sent from my iPhone using Home Brew

I'm kind of a novice at this, but I wounder if someone could point me in the right direction. I'm trying to change a few variables in some of the files, but don't know where to begin on how to make the new arduino files reflect any changes that I make. Reason is I'm trying to increase the hysteresis for my glycol chiller, and would like to try my hand at making the changes myself. Can anyone help me with the procedure or link appropriate websites?

On another note about the relays, any idea what the maximum current these will withstand in regards to inrush current? Reason I ask is my chiller uses a 5000 btu ac, with a current draw of something like 4-6 amps, but the start up has a spike of about 22 amps near as I can tell, my kill-a-watt isn't quite quick enough to register it, but from what I can find on the net this seems to be what they can draw when they fire up. Any idea on how this would affect the longevity of the internal relay? Just to be on the safe side I ordered a contactor to take the load, but I guess I'm still curious.

On another note about the relays, any idea what the maximum current these will withstand in regards to inrush current? Reason I ask is my chiller uses a 5000 btu ac, with a current draw of something like 4-6 amps, but the start up has a spike of about 22 amps near as I can tell, my kill-a-watt isn't quite quick enough to register it, but from what I can find on the net this seems to be what they can draw when they fire up. Any idea on how this would affect the longevity of the internal relay? Just to be on the safe side I ordered a contactor to take the load, but I guess I'm still curious.

hmm, finally looking through 1.06, am I reading this correctly that you have increased max f temp correction from 5* to 10*? And hysteresis to 10* as well? If I'm reading that right you have just made my day!

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

hmm, finally looking through 1.06, am I reading this correctly that you have increased max f temp correction from 5* to 10*? And hysteresis to 10* as well? If I'm reading that right you have just made my day!

Yes, that is correct.

If you are limited by the hysteresis or some other setting that is too restrictive, I'd be glad to make the change and incorporate it.

If you'd still like to get your hands dirty, then it is pretty easy to build your own firmware, as I include a build script that compiles the firmware and includes the hex data in the sketch. You need SDCC and GPUTILS and also make, sed, bash and perhaps some other unix commands as well for this. If you don't run Linux, then a virtual machine with Linux might be the way, but it could possibly be made to work with Cygwin or something similar.

Cheers!

hmm, that sounds like a more trouble than I had originally thought! The 10* changes fit everything for me perfectly now. If someone else was to use a glycol chiller they may or may not desire a few more degrees for that, I'm not really sure as I haven't really used mine much yet. I have the coolant set to 25* with 10* hysteresis and that seems to be pretty close to what others are doing I think. I'll be testing out 1.06 soon, but I don't have a second probe yet, or even know what I would do with one in my setup. I could potentially need one to be placed on the side of my sanke fermenter to prevent undershooting temps. If you are taking requests... I would prefer to have a blank screen when they are soft off, but I remember why you did it and doesn't really affect usage. Would it be possible to have one of the dots on the lcd on if it is in soft off? That might help with people knowing it works and has power, and be a little sleeker than "off." Just a thought. Hard to believe how much smarter you have made these!

For those in the hunt for a cheap Arduino Uno, I just ordered this one which appears from the pics to be an authentic Arduino, $13.75 fulfilled by Amazon:

http://www.amazon.com/dp/B00MFL3GQW/?tag=skimlinks_replacement-20

http://www.amazon.com/dp/B00MFL3GQW/?tag=skimlinks_replacement-20

Last edited by a moderator:

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Hi guys!

I'm been planning a few... let's call them changes, because I don't really know yet if you'd consider them improvements yet, for v1.07.

As orangehero mentioned in post #1235, he would like the option to show temperature in 'soft off' mode + he was annoyed at the filter resetting on power on again (due to an actual reset I might add).

This got me thinking yet again about the 'soft off mode' (that I still don't really like, but is a whole lot better now at least). What I am thinking is, that what is the point of the 'off mode'? Well, you want to disengage the output relays (and alarms and what not). I really don't see any reason the temperature couldn't be shown. After all if you want the unit really off, then cut the power. What I am proposing is remove the the 'soft off' junk and instead have an 'off' run mode. That is, the power button will no longer turn off at all, but you'd need to go to 'Set' - 'rn' and select 'off'. This also means you can't do an 'off' then continue to run the profile, you'd need start the profile and jump to where you want to continue from in that case.In this new 'run mode off', temperatures will show as usual, only without thermostat action (relays disengaged). I'm thinking the LED to indicate profile running, could change to on in thermostat mode, flashing in profile mode and off in off mode.

Also, there is no room for any more settings, so I'm thinking of dropping a profile (from 6 to 5).

So far, I guess this does not seem like much improvement at all, but here is the thing. I'm thinking of adding a parameter to the end of each profile, that would dictate the run mode to switch to when the profile ends. I think this could be a really cool thing. That means you could run any profile once this one is done (i.e. loop the profile, or link profiles, or link and loop) or switch to thermostat mode (as is forced now) or switch 'off'.

This makes the firmware a LOT more versatile. And then it can be used outside brewing also. I might even use one to control my electric car engine heater (turn on on weekday mornings, but not on weekends and even have it not turning on if weather is 'warmish').

What do you guys think?

I'm been planning a few... let's call them changes, because I don't really know yet if you'd consider them improvements yet, for v1.07.

As orangehero mentioned in post #1235, he would like the option to show temperature in 'soft off' mode + he was annoyed at the filter resetting on power on again (due to an actual reset I might add).

This got me thinking yet again about the 'soft off mode' (that I still don't really like, but is a whole lot better now at least). What I am thinking is, that what is the point of the 'off mode'? Well, you want to disengage the output relays (and alarms and what not). I really don't see any reason the temperature couldn't be shown. After all if you want the unit really off, then cut the power. What I am proposing is remove the the 'soft off' junk and instead have an 'off' run mode. That is, the power button will no longer turn off at all, but you'd need to go to 'Set' - 'rn' and select 'off'. This also means you can't do an 'off' then continue to run the profile, you'd need start the profile and jump to where you want to continue from in that case.In this new 'run mode off', temperatures will show as usual, only without thermostat action (relays disengaged). I'm thinking the LED to indicate profile running, could change to on in thermostat mode, flashing in profile mode and off in off mode.

Also, there is no room for any more settings, so I'm thinking of dropping a profile (from 6 to 5).

So far, I guess this does not seem like much improvement at all, but here is the thing. I'm thinking of adding a parameter to the end of each profile, that would dictate the run mode to switch to when the profile ends. I think this could be a really cool thing. That means you could run any profile once this one is done (i.e. loop the profile, or link profiles, or link and loop) or switch to thermostat mode (as is forced now) or switch 'off'.

This makes the firmware a LOT more versatile. And then it can be used outside brewing also. I might even use one to control my electric car engine heater (turn on on weekday mornings, but not on weekends and even have it not turning on if weather is 'warmish').

What do you guys think?

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Great! Even when I thought there was no room for projection you find the road. Soon this gadget can fly us to the moon

Had to look it up, but I would say from my quick read that the specs of the AGC is comparable to the the MCU in the STC

Edit: That is, in the same order of magnitude of complexity, clock frequency et.c....

LOVE the new proposals! Can't wait to upgrade to 1.07! Dropping a profile to add the flexibility of linking profiles is awesome. I think the options are awesome. You could have more ramps during ferment for either ale or lager and then just link them to a standard crash cool profile. 2 different ale profiles and 2 different lager profiles with 1 crash cool... I need to add a terminal mount to my box so I can upgrade without opening it up!

Regarding removal of the soft off...

What I do with my current thermostat is that before I open the chamber door, I turn off the thermostat (turns off fan, heater, whatever.) After I'm done, I turn it back on. I don't want

the ambient air being pulled into the cabinet while I'm working in there.

Thus, having soft off would be nice. Having to pull the plug is not necessarily easy. Its in back, there are multiple controllers, etc. Pushing the power button is very nice.

Like the chaining of profiles. Power user feature for sure.

What I do with my current thermostat is that before I open the chamber door, I turn off the thermostat (turns off fan, heater, whatever.) After I'm done, I turn it back on. I don't want

the ambient air being pulled into the cabinet while I'm working in there.

Thus, having soft off would be nice. Having to pull the plug is not necessarily easy. Its in back, there are multiple controllers, etc. Pushing the power button is very nice.

Like the chaining of profiles. Power user feature for sure.

This makes the firmware a LOT more versatile. And then it can be used outside brewing also. I might even use one to control my electric car engine heater (turn on on weekday mornings, but not on weekends and even have it not turning on if weather is 'warmish').

Love it! I'll be waiting for the version where you're running an STC-1000 coffee machine with hot or iced beverages ready in the morning depending on the outside temp.

ClunkClunk

Well-Known Member

Speaking of STC-1000+ with other things:

Does the 99 °C maximum temperature still apply? I'd love to use one to control my electric meat smoker's electric heating element, trying to target temps around 225F/107C.

Also, as anyone ever seen a sharp probe sensor for sticking in meat that would work with the STC-1000? I could set a target meat temp as an alternate.

Does the 99 °C maximum temperature still apply? I'd love to use one to control my electric meat smoker's electric heating element, trying to target temps around 225F/107C.

Also, as anyone ever seen a sharp probe sensor for sticking in meat that would work with the STC-1000? I could set a target meat temp as an alternate.

Bigdaddyale

Well-Known Member

https://www.homebrewtalk.com/f51/probes-stc-1000-a-337938/

Looks like it would be easy enough to make your own probe

Looks like it would be easy enough to make your own probe

orangehero

Well-Known Member

As orangehero mentioned in post #1235, he would like the option to show temperature in 'soft off' mode + he was annoyed at the filter resetting on power on again (due to an actual reset I might add).

The filter reset isn't really an issue, just something I noticed and wasn't sure about. I actually thought something major was wrong at first since the temp display defaults to sensor 2 when you come out of soft off.

This got me thinking yet again about the 'soft off mode' (that I still don't really like, but is a whole lot better now at least). What I am thinking is, that what is the point of the 'off mode'? Well, you want to disengage the output relays (and alarms and what not). I really don't see any reason the temperature couldn't be shown. After all if you want the unit really off, then cut the power. What I am proposing is remove the the 'soft off' junk and instead have an 'off' run mode. That is, the power button will no longer turn off at all, but you'd need to go to 'Set' - 'rn' and select 'off'. This also means you can't do an 'off' then continue to run the profile, you'd need start the profile and jump to where you want to continue from in that case.In this new 'run mode off', temperatures will show as usual, only without thermostat action (relays disengaged). I'm thinking the LED to indicate profile running, could change to on in thermostat mode, flashing in profile mode and off in off mode.

Also, there is no room for any more settings, so I'm thinking of dropping a profile (from 6 to 5).

Can you keep soft off as well as adding SET->RN->OFF? How about my original suggestion of alternate temp display for soft off? For example press POWER quickly to toggle temp display in both on mode and soft off and hold POWER to go between on and soft off.

I would have no problems with one less profile. Even 4 profiles would be sufficient, it's not that difficult to change a profile and takes me less than a minute.

LOVE the new proposals! Can't wait to upgrade to 1.07! Dropping a profile to add the flexibility of linking profiles is awesome. I think the options are awesome. You could have more ramps during ferment for either ale or lager and then just link them to a standard crash cool profile. 2 different ale profiles and 2 different lager profiles with 1 crash cool... I need to add a terminal mount to my box so I can upgrade without opening it up!

What kind of crash cool profile do you use? I just set it to thermostat mode and chill down to 1°C as fast as the fridge can go and keep the fermentor in there until time to transfer. Or you can just add one more step to the profile to crash cool. 9 setpoints per profile is more than enough for me. I don't crash cool by a set schedule though, I go by when the beer is at the proper level of attenuation.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

The filter reset isn't really an issue, just something I noticed and wasn't sure about. I actually thought something major was wrong at first since the temp display defaults to sensor 2 when you come out of soft off.

I'm gonna try and fix both of the issues for v1.07.

orangehero said:Can you keep soft off as well as adding SET->RN->OFF? How about my original suggestion of alternate temp display for soft off? For example press POWER quickly to toggle temp display in both on mode and soft off and hold POWER to go between on and soft off.

The 'soft off' and 'run mode off' are conceptually different. But since the 'soft off' seems to really be something ppl want, I'm gonna try and keep it. It might be confusing to have two off modes, but that is the way it has to be if 'soft off' is going to stay. During soft off temperature cannot be displayed (I looked in to it) as the timer for handling temp and temp control is turned off. During run mode off, it will be displayed though.

I'd like to avoid confusion between the off modes if possible. So I'm thinking maybe changing the names? I like run mode 'off' since it prints nicely on the 7-segment display and says pretty much what it does. Maybe changing the name of soft 'off' to something else? Instead of showing 'off' on the display, I could consider turning display off and only have a LED flash to indicate it's in standby. Hmm... Standby, that could work as a new name? Couldn't it? Any other ideas?

orangehero said:I would have no problems with one less profile. Even 4 profiles would be sufficient, it's not that difficult to change a profile and takes me less than a minute.

I'm considering making the profiles shorter now instead. Having 8 setpoints and 7 durations + next run mode setting. That would even allow for 7 profiles currently (but wont add much extra space for new parameters), if more parameters are needed later on then a profile could be dropped then. As you said, 10 setpoints are more than enough in most cases anyway. With linking profiles, then you can overcome the limit of shorter profiles if needed anyway.

All opinions are welcome.

des

Member

FWIW flashing leds are usually annoying, so I'd stay away from them

Regarding the new-off mode, wouldn't it just be a termometer mode?

What about:

1 power button click -> termometer mode (aka: disengage relays)

1 power button hold -> current soft-mode (I like it better with no off word, but can live with)

Love the chaining, don't mind about shorting profiles, although keep in mind that holding temp with ramping uses 2 setpoint so the get used up faster with ramping enabled. I still think we are ok cutting to 8 sp, specially since chaining will help if you run short

Regarding the new-off mode, wouldn't it just be a termometer mode?

What about:

1 power button click -> termometer mode (aka: disengage relays)

1 power button hold -> current soft-mode (I like it better with no off word, but can live with)

Love the chaining, don't mind about shorting profiles, although keep in mind that holding temp with ramping uses 2 setpoint so the get used up faster with ramping enabled. I still think we are ok cutting to 8 sp, specially since chaining will help if you run short

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

FWIW flashing leds are usually annoying, so I'd stay away from them

Regarding the new-off mode, wouldn't it just be a termometer mode?

What about:

1 power button click -> termometer mode (aka: disengage relays)

1 power button hold -> current soft-mode (I like it better with no off word, but can live with)

Love the chaining, don't mind about shorting profiles, although keep in mind that holding temp with ramping uses 2 setpoint so the get used up faster with ramping enabled. I still think we are ok cutting to 8 sp, specially since chaining will help if you run short

Usually yes, but it can be more or less annoying. For example 100ms on, 1 sec off on one of the dot-LED's is really not that annoying, but it still shows 'life'.

Yes, it would pretty much be a thermometer. But In terms of regulation it would be regulation = off. I don't think calling it 'thermometer mode' would be the best way to describe the action of the run mode when using it in a profile. Besides there is a 'th' mode which is thermostat mode. How would you show 'thermometer mode' using max 3 7-segment LEDs in a non-ambiguous way?

1 click on power button switches between probes, so I can't use that. And in 'soft off' (or 'standby') temperature reading are not available.

- Joined

- Nov 26, 2013

- Messages

- 9,920

- Reaction score

- 24,072

FWIW 4, link able, 8 step profiles are more than enough. I have no real opinion of off modes as I am casual brewer and unplug.

But this thing doth rock!

Sent from my iPod touch using Home Brew

But this thing doth rock!

Sent from my iPod touch using Home Brew

Similar threads

- Replies

- 2

- Views

- 950