alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Well, not quite. The actual problem is that it has an entirely different MCU that is not compatible. And the only datasheet I can find is in Chinese.

I am brewing a Saison this weekend and using Danstar Belle Saison yeast.

I was thinking I would start out at 68f for 84 hours, then ramp up to 75f over the next 48 hours, hold 75f for 36 hours, then ramp up to 85f over 48 hours, finishing up the final 36hrs at 85f.

I've never done a saison - does this sound about right for a saison profile? Danstar says anything above 63f give "Quick start and vigorous fermentation"

That sounds fine. I did a saison with that yeast earlier this year and held it at 68 for 2 days then ramped it 1F a day until 78F and held it there for a few weeks. I never had an issue with the stalling you get with the Dupont strain. This one finished at 1.001 for me.

I'm a software engineer but I don't dabble in hardware much. What are the limitations? Could the stc be controlled via wifi? Ie could we connect the device to a network with a wifi card? Basically, my goal would be able to make temperature changed on a computer and have automatically push to the device

Sent from my iPhone using Home Brew

Thanks. I'll definitely pull mine out after I keg the batch that's using the temp controller.

I'm a software engineer but I don't dabble in hardware much. What are the limitations? Could the stc be controlled via wifi? Ie could we connect the device to a network with a wifi card? Basically, my goal would be able to make temperature changed on a computer and have automatically push to the device

Arduino has a cheap Ethernet add on shield, and others show how to use NTC or one-wire thermistors and web based logging to Xively,

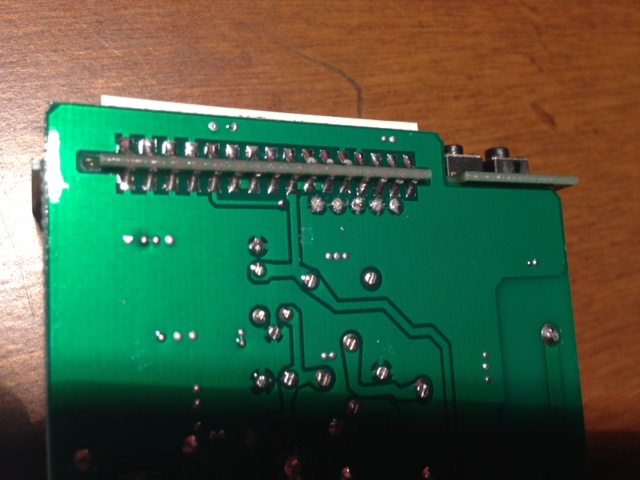

Wow... Looks like the solder pads came off... yikes.I received my new STC-1000 (the correct one!), took it apart and de-soldered the programming holes (What a PITA!). I've done a little soldering/de-soldering before, never had this much trouble. I had no luck with my sucker so reverted to blowing it out. It made a mess of the top side and took a while to get it cleaned up with some de-soldering braid but finally got all the holes separated from each other. My concern is the conductivity between four of the five and some of the connections on the long header row adjacent to them. I drew red lines showing which connections have conductivity between them (the ground is connected to 2 and the other 3 are connected to just 1 ea.) and was hoping that someone could verify that these are either supposed to have connections or that I still have stray solder connecting things that shouldn't be. If anyone has one open and a meter handy, could you verify it for me before I try to flash this and fry something?

Thanks!

BTW, depending on what setup you are looking for with brewpi, I am currently working on getting brewpi running on the Arduino Yún, so that you will not need the raspberry pi. Everything on one (UNO sized) board, with WiFi and everything.

That depends on what you mean.

Of course you can use the same UNO, but not at the same time of course. Depending on your setup, it might be a bit of work to 'free' the UNO (aside from mounting), you may want to dump program and eeprom after brewpi duty so it can be restored one you have updated the STC.

BTW, depending on what setup you are looking for with brewpi, I am currently working on getting brewpi running on the Arduino Yún, so that you will not need the raspberry pi. Everything on one (UNO sized) board, with WiFi and everything.

I received my new STC-1000 (the correct one!), took it apart and de-soldered the programming holes (What a PITA!). I've done a little soldering/de-soldering before, never had this much trouble. I had no luck with my sucker so reverted to blowing it out. It made a mess of the top side and took a while to get it cleaned up with some de-soldering braid but finally got all the holes separated from each other. My concern is the conductivity between four of the five and some of the connections on the long header row adjacent to them. I drew red lines showing which connections have conductivity between them (the ground is connected to 2 and the other 3 are connected to just 1 ea.) and was hoping that someone could verify that these are either supposed to have connections or that I still have stray solder connecting things that shouldn't be. If anyone has one open and a meter handy, could you verify it for me before I try to flash this and fry something?

Thanks!

Thank you so much alphaomega for all that you have done with this neat little device. I just got a 1.0 in from ebay (mixtea), and am waiting for my uno to get off the slow boat before I dive in. With regards to the Yun, did you ever doubt there wouldn't be any interest? Now there is something else on my must have list! Again, great work and thanks for sharing your talents! You have made many people very happy!

Hi!

I have uploaded a change to the work branch on GitHub, if anyone is able to help test it, then that would be great.

The only change is that I think I have managed to improve on the approximative ramping, so instead of 8 steps maximum it is now 64 steps maximum. If this works out ok (which I think it will, but I have not done ANY testing myself yet), then it is probably good enough that you don't need to care that it is not true ramping. For example for simplicity's sake say you run a ramp for 8 days, this would mean that SP would be updated once a day with v1.00 but every third hour with the new version (v1.01).

Does anyone have a link to an Amazon seller where they have gotten the proper STC 1.0 board? I already have a STC but it is v1.1 unfortunately. I'd like to order another but I'd really like to get the v1.0.