alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

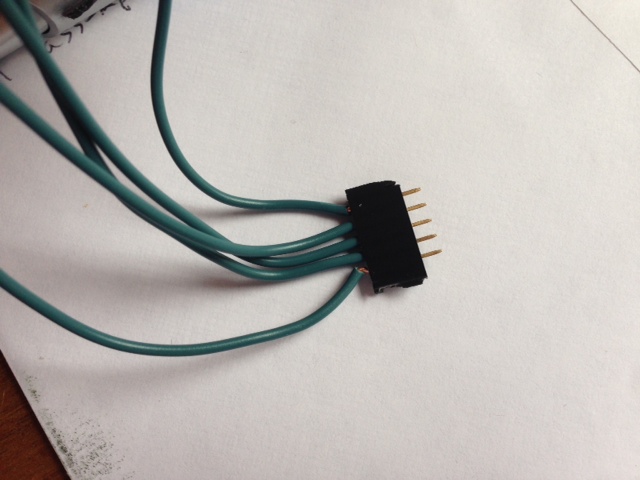

I have a couple old PC wiring harnesses laying around. Is there any reason I couldn't use one of the four wire connectors to solder in a permanent header to both the STC and the Arduino? That way you just clip it in if you need to flash. And, no cost.

Sent from my iPhone using Home Brew

One reason might be that you need 5 wires. You could get by with 4 if you allow target to supply power (i.e. skip 5v line and instead have STC-1000 provide power from mains), but you'll have to decide yourself if you are willing to do that (personally I would want to avoid it).

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)