You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stc-1000+

- Thread starter alphaomega

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Atoughram, what are you using to log with?

Arduino connected to Xively.com

https://www.homebrewtalk.com/f51/real-time-online-fermentation-temperature-monitor-60-a-370966/

FuzzeWuzze

I Love DIY

Arduino connected to Xively.com

https://www.homebrewtalk.com/f51/real-time-online-fermentation-temperature-monitor-60-a-370966/

Its nice to see that project live on even after i stopped really supporting it a bunch of you guys took that over lol

Does it still work alright? I moved away from it when COSM changed to Xively because i didnt like how they removed a ton of features going from beta to live...i bet they got a bunch of angry people and added them back

Its nice to see that project live on even after i stopped really supporting it a bunch of you guys took that over lol

Does it still work alright? I moved away from it when COSM changed to Xively because i didnt like how they removed a ton of features going from beta to live...i bet they got a bunch of angry people and added them back

I've only played with it for a week or so, but it's all your code modified for Xively and three channels. I'll soon add a fourth in a thermowell in my fermentor. Thanks for all the help!

Installed the A/C unit on the chamber today... looks like the unit is no good anymore... It's have a rough time getting the chamber to less than ambient...

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

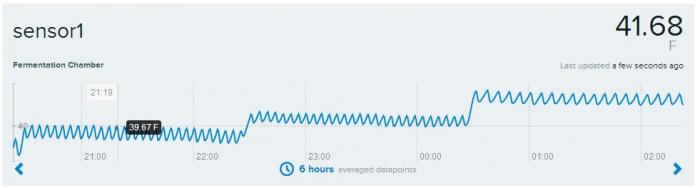

I've started a low temp step profile - https://xively.com/feeds/2140417376

started at an indicated 31f - and raised it three degrees every two hours - stopping at 40f (IIRC) and then dropping back down to 35f.. I actually have some beer in there...

I calibrated the STC for room temperature but it's a few degrees off near freezing.

One other item Alphaomega - the original STC-1000 shut off when you held the power button down but I noticed that this firmware does not. How hard would that be to implement?

started at an indicated 31f - and raised it three degrees every two hours - stopping at 40f (IIRC) and then dropping back down to 35f.. I actually have some beer in there...

I calibrated the STC for room temperature but it's a few degrees off near freezing.

One other item Alphaomega - the original STC-1000 shut off when you held the power button down but I noticed that this firmware does not. How hard would that be to implement?

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Have you downloaded recently?

I have allready implemented "power off" functionality.

I have allready implemented "power off" functionality.

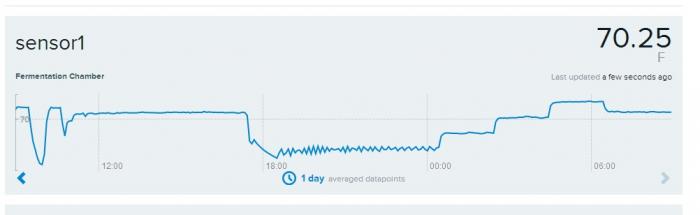

The 72 hour step test is going great. It has one step left to complete.

I'll post the data when it completes. The only issues were due to my fridge setup and not the controller. Due to the nature of a cheap dorm fridge, I am getting quite a but of overshoot as the thermal momentum carries the temperature past the set point after the STC shuts the compressor off. Also, I got a bit of overshoot on the heat side because the heater is too big for the small space (60W and indirect).

I may try it again with a smaller direct heater and a fan in the fridge to see if I can tone down the overshoot.

Nothing wrong with the controller though, unless Alpha wants to build PID controls into it (ha ha).

I'll post the data when it completes. The only issues were due to my fridge setup and not the controller. Due to the nature of a cheap dorm fridge, I am getting quite a but of overshoot as the thermal momentum carries the temperature past the set point after the STC shuts the compressor off. Also, I got a bit of overshoot on the heat side because the heater is too big for the small space (60W and indirect).

I may try it again with a smaller direct heater and a fan in the fridge to see if I can tone down the overshoot.

Nothing wrong with the controller though, unless Alpha wants to build PID controls into it (ha ha).

Have you downloaded recently?

I have allready implemented "power off" functionality.

The version I had is what you had on Github on 3/22/14. Maybe I'm not holding the power button down long enough.... I'll check.

EDIT - Checked - Yes - it works, you hold the power down a little longer than original programming but works perfect! Sorry about that!

Also - for those of you squeamish at soldering - those solder pads are mighty small - you could use a pin header. Get some 5 pin header and solder some wires to it (I plugged mine into a ribbon cable you could also use an old IDE disk drive ribbon cable out of a computer) Plug the other end of the wires into the appropriate spots on the Arduino board, hold the pin header on the contacts spots and flash it.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

The version I had is what you had on Github on 3/22/14. Maybe I'm not holding the power button down long enough.... I'll check.

EDIT - Checked - Yes - it works, you hold the power down a little longer than original programming but works perfect! Sorry about that!

Good to know, maybe I should shorten the delay a bit then.

For those squeamish about soldering -- find an old broken piece of electronics in your closet and go to town on it. Seriously. Soldering isn't THAT bad, and you might as well learn at SOME point.

The solder points on this controller board are actually rather large, when compared to soldering on many applications (ie. Playstation 2 mod chip). The biggest thing you gotta be careful with is to not cross solder onto either another pin, or one of the contacts where the screen meets the board. And also to keep the soldering point low-profile. Otherwise, you run the risk of the cover not being able to slide back on (from personal experience).

Alpha, a couple things:

I'm digging the increasing frequency timer that speeds up selection of temperatures -- truly an essential feature. Question -- I noticed a new light dot is on in the top right of the screen, just above the smaller number that represents tenths. What is this light for? I'm pretty sure it wasn't there previously.

Finally -- this looks GREAT man! Like Disney7, I was out of town over the weekend, but I've done plenty of step testing starting back last Thursday, and this thing is definitely ready to ferment a live batch of beer! Congrats man, your hard work has paid off big time! Now we just need some kickass stickers to rep your "brand". Come up with a logo and let's get some sort of "Hacked by [insertbrandhere]" sticker going on with a skull and crossbones!

P.S.....

Agreed. I thought the feature was broken too, til I realized it was just a longer hold-press. I'm not sure what stock is, but I'm guessing 1.5-2 secs.

The solder points on this controller board are actually rather large, when compared to soldering on many applications (ie. Playstation 2 mod chip). The biggest thing you gotta be careful with is to not cross solder onto either another pin, or one of the contacts where the screen meets the board. And also to keep the soldering point low-profile. Otherwise, you run the risk of the cover not being able to slide back on (from personal experience).

Alpha, a couple things:

I'm digging the increasing frequency timer that speeds up selection of temperatures -- truly an essential feature. Question -- I noticed a new light dot is on in the top right of the screen, just above the smaller number that represents tenths. What is this light for? I'm pretty sure it wasn't there previously.

Finally -- this looks GREAT man! Like Disney7, I was out of town over the weekend, but I've done plenty of step testing starting back last Thursday, and this thing is definitely ready to ferment a live batch of beer! Congrats man, your hard work has paid off big time! Now we just need some kickass stickers to rep your "brand". Come up with a logo and let's get some sort of "Hacked by [insertbrandhere]" sticker going on with a skull and crossbones!

P.S.....

Good to know, maybe I should shorten the delay a bit then.

Agreed. I thought the feature was broken too, til I realized it was just a longer hold-press. I'm not sure what stock is, but I'm guessing 1.5-2 secs.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Question -- I noticed a new light dot is on in the top right of the screen, just above the smaller number that represents tenths. What is this light for? I'm pretty sure it wasn't there previously.

No it wasn't, it's the 'degree' symbol. It's lit whenever a temperature is displayed (the 'C' is lit aswell in the celsius version).

Edit: And I'm happy to hear you like the button acceleration, I'm pretty pleased myself with the solution and how well it turned out to work.

Here are the results of my test:

Google Chart Link

The programming was:

Looks like the STC worked perfectly.

My chamber needs a tweak or two to tone down the overshoot on both the heat and cool sides, but that doesn't have anything to do with the STC+.

Couple of notes on the data:

At 3pm on 3/24 the slight rise in temp is where I opened the fridge door for the first time during the test.

The two sharp dips in room temp are where the garage bay door was opened.

At 6am on 3/23 I'm not sure what happened. For some reason the beer temp became very stable for several hours. If anyone has any ideas, lemme know.

BTW, the beer temp probe was taped to the outside of a can of miller lite (don't ask) and covered with a custom fitted piece of 3/4" rigid foam insulation.

Google Chart Link

The programming was:

Code:

Setting Temp Setting Hours

SP0 35 DH0 4

SP1 40 DH1 8

SP2 45 DH2 6

SP3 50 DH3 10

SP4 55 DH4 9

SP5 60 DH5 10

SP6 68 DH6 6

SP7 50 DH7 11

SP8 40 DH8 8

SP9 33Looks like the STC worked perfectly.

My chamber needs a tweak or two to tone down the overshoot on both the heat and cool sides, but that doesn't have anything to do with the STC+.

Couple of notes on the data:

At 3pm on 3/24 the slight rise in temp is where I opened the fridge door for the first time during the test.

The two sharp dips in room temp are where the garage bay door was opened.

At 6am on 3/23 I'm not sure what happened. For some reason the beer temp became very stable for several hours. If anyone has any ideas, lemme know.

BTW, the beer temp probe was taped to the outside of a can of miller lite (don't ask) and covered with a custom fitted piece of 3/4" rigid foam insulation.

I'm going to add a fan to the ferment chamber and drop the heater wattage down to see if I can get better stability (and run the test again), but that just has to do with this particular ferment chamber.

At this point I feel very comfortable with the STC+ and I will be using it for my next brew.

At this point I feel very comfortable with the STC+ and I will be using it for my next brew.

At this point I feel very comfortable with the STC+ and I will be using it for my next brew.

Me too Apple Cider...

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

I'm going to add a fan to the ferment chamber and drop the heater wattage down to see if I can get better stability (and run the test again), but that just has to do with this particular ferment chamber.

At this point I feel very comfortable with the STC+ and I will be using it for my next brew.

Be sure to get the latest changes. I think you'll like the button acceleration and I also fixed two cosmetic bugs.

Be sure to get the latest changes. I think you'll like the button acceleration and I also fixed two cosmetic bugs.

When did you post the latest changes? I think I have the button acceleration already.

I'm going to add a fan to the ferment chamber and drop the heater wattage down to see if I can get better stability (and run the test again), but that just has to do with this particular ferment chamber.

At this point I feel very comfortable with the STC+ and I will be using it for my next brew.

Comments like this one make this deal timely to say the least. I think I may need to pick up a couple more.

http://www.homebrewfinds.com/2014/03/reader-tip-stc-1000-dual-stage-temp.html

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

When did you post the latest changes? I think I have the button acceleration already.

Yes, you do. I pushed the two bugfixes yesterday. One was to not listen to buttons other than 'power' when in power off. The other to turn off degree symbol when pressinf down button.

The other to turn off degree symbol when pressing down button.

I'll have to check and see if I have this. Time for sub-versions?

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

I'll have to check and see if I have this. Time for sub-versions?

No, that was a pure bug. When pressing 'down' while current temperature is showing, ether 'th' or or current profile info is shown. I had forgotten to turn of the degree symbol at that point. It should only show when a temperature is displayed.

But I really do think this has come a long way. I just like to wait a week or so, and see if more bugs turn up. Then I'll tag a version v1.0.

I checked, and it is the older version. Flash time!No, that was a pure bug. When pressing 'down' while current temperature is showing, ether 'th' or or current profile info is shown. I had forgotten to turn of the degree symbol at that point. It should only show when a temperature is displayed.

But I really do think this has come a long way. I just like to wait a week or so, and see if more bugs turn up. Then I'll tag a version v1.0.

- Joined

- Nov 26, 2013

- Messages

- 9,918

- Reaction score

- 24,072

My chamber needs a tweak or two to tone down the overshoot on both the heat and cool sides, but that doesn't have anything to do with the STC+.

disney7, I'll be repurposing a large dorm fridge for FermChamber. Do you think a small fan and a small heater (e.g. amazon) inside will be too much and overshoot like you've seen with your setup or do you think the fan will even out your temp swings?

Last edited by a moderator:

I'm re-running the test right now with a fan (constant) and a 25W bulb (instead of the 60W I had before). So far it isn't making any difference in the overshoot (about 1*F total swing). It is just causing the fridge to run a shorter period of time and more frequently (4 cycles per hour instead of 3). The overshoot is about the same.

My test isn't a very good one for fermentation. I was initially just trying to see if the STC+ was stepping properly.

I have a single can of beer in there that things are taped to. If you had 640 oz of liquid in there instead of 12, I think the thermal mass of the greater volume of liquid would smooth things out quite a bit. The fridge should run less often and you would possibly see the swings reduce in amplitude.

I think a small fan is a good idea, especially in a dorm fridge that has no fan, in order to even the temps out in the entire enclosure.

The only way to really smooth things out would be to use a PID controller that can look at the temp change rate and shut the heat/cool off before the set point is reached.

I thought about asking Alpha if it would be possible to add heat/cool settings to open the relays when you are X degrees from reaching the set point during a cooling or heating cycle. However, that would work great for dead liquids like water (once you had it dialed in), but would probably be useless with something that generates its own heat like a fermenting beer. You'd be chasing that setting around as fermentation started and finished.

But, I think a 1*F total swing that averages around your set point is plenty stable for fermenting. I doubt pro breweries have much better control.

I think I will stop my current test and put a full carboy of water in there and see how it does.

My test isn't a very good one for fermentation. I was initially just trying to see if the STC+ was stepping properly.

I have a single can of beer in there that things are taped to. If you had 640 oz of liquid in there instead of 12, I think the thermal mass of the greater volume of liquid would smooth things out quite a bit. The fridge should run less often and you would possibly see the swings reduce in amplitude.

I think a small fan is a good idea, especially in a dorm fridge that has no fan, in order to even the temps out in the entire enclosure.

The only way to really smooth things out would be to use a PID controller that can look at the temp change rate and shut the heat/cool off before the set point is reached.

I thought about asking Alpha if it would be possible to add heat/cool settings to open the relays when you are X degrees from reaching the set point during a cooling or heating cycle. However, that would work great for dead liquids like water (once you had it dialed in), but would probably be useless with something that generates its own heat like a fermenting beer. You'd be chasing that setting around as fermentation started and finished.

But, I think a 1*F total swing that averages around your set point is plenty stable for fermenting. I doubt pro breweries have much better control.

I think I will stop my current test and put a full carboy of water in there and see how it does.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

With larger thermal mass cycling will probably reduce some, but I agree that 1F temp swing is not bad at all. Even PID control will not solve the problem, just look at brew pi. They use PID to calc setpoint for fridge temperature (not actual beer temperature) and on top of that a pretty clever peak detection algorithm to determine how long compressor should cycle.

So, I think in order to do a little better, you'd need to go a lot more complex. And in the end, you just can't avoid a trade off on how short cycles you are willing to tolerate.

So, I think in order to do a little better, you'd need to go a lot more complex. And in the end, you just can't avoid a trade off on how short cycles you are willing to tolerate.

Those swings aren't bad at all. My chamber swings about .4-.6 C with the STC-1000 as is.

I've been wanting to flash one of my extras and jump in on this but i've just been too busy at the moment. Though I may have time tonight.

I've been wanting to flash one of my extras and jump in on this but i've just been too busy at the moment. Though I may have time tonight.

Similar threads

- Replies

- 2

- Views

- 950

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)