Need some help here. I went to go pull a sample of my Märzen that is conditioning in the tank. I just recently got the sampling coil to use so I can pull carbonated samples. I hook up the sampling coil and pour a .5L mug. I go to close the sample valve and it won't stop flowing. I unhook the sampling coil and beer is just flowing out of the sampling valve.

After complete panic and losing an additional 40 oz on top of what I poured, I quickly depressurized the tank from 12 psi to 0 psi by opening the ball valve on the blow off cane, thinking that might help stop or slow the leak. It slowed it a bit, but not enough.

I plugged it with my thumb to give myself a minute to think. I started messing with the valve thinking of something was stuck, maybe I could jar it back in place. I ultimately got it to show down to a fast drip. Right around the same time, I realized if I put downward pressure on the top of the knob, it stops completely. So...

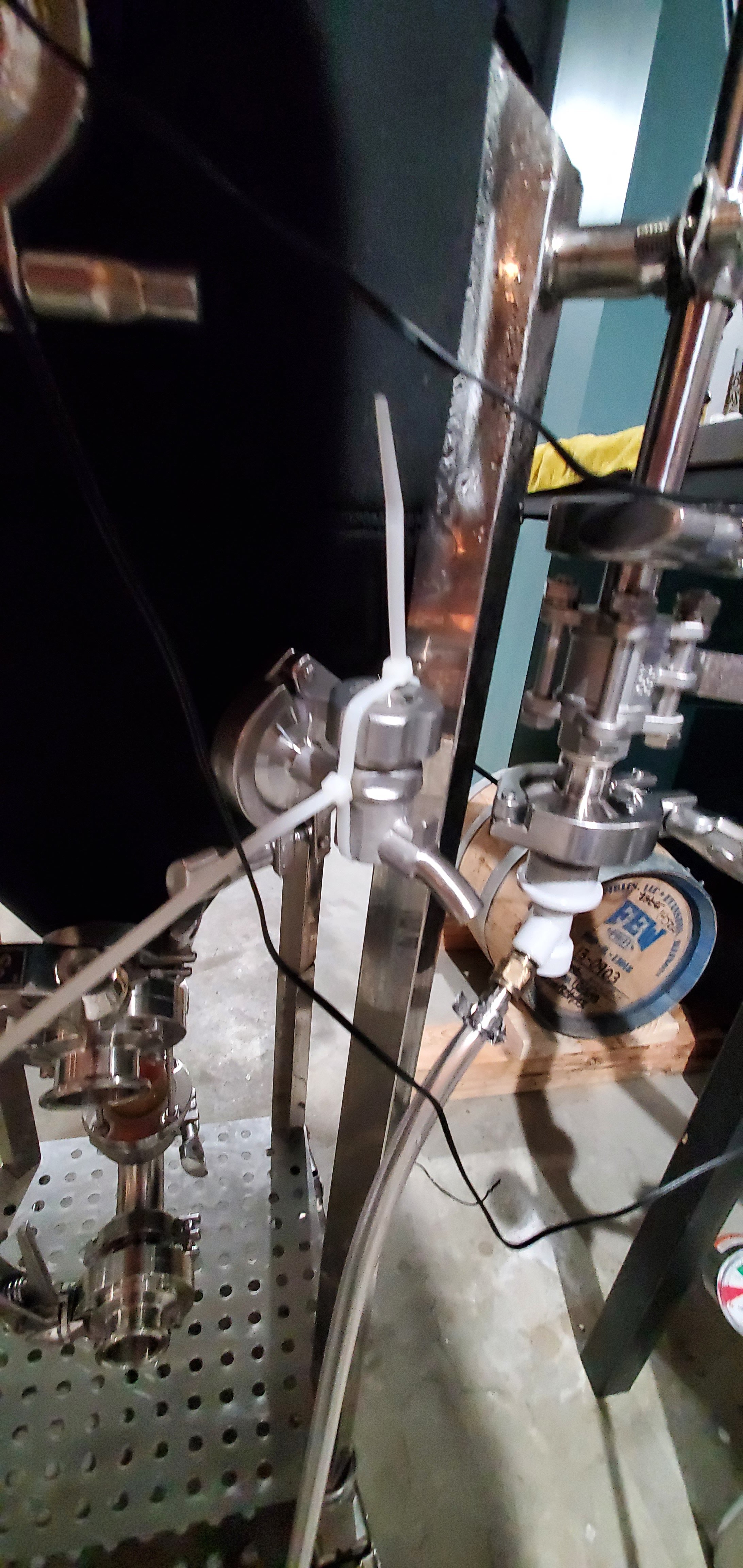

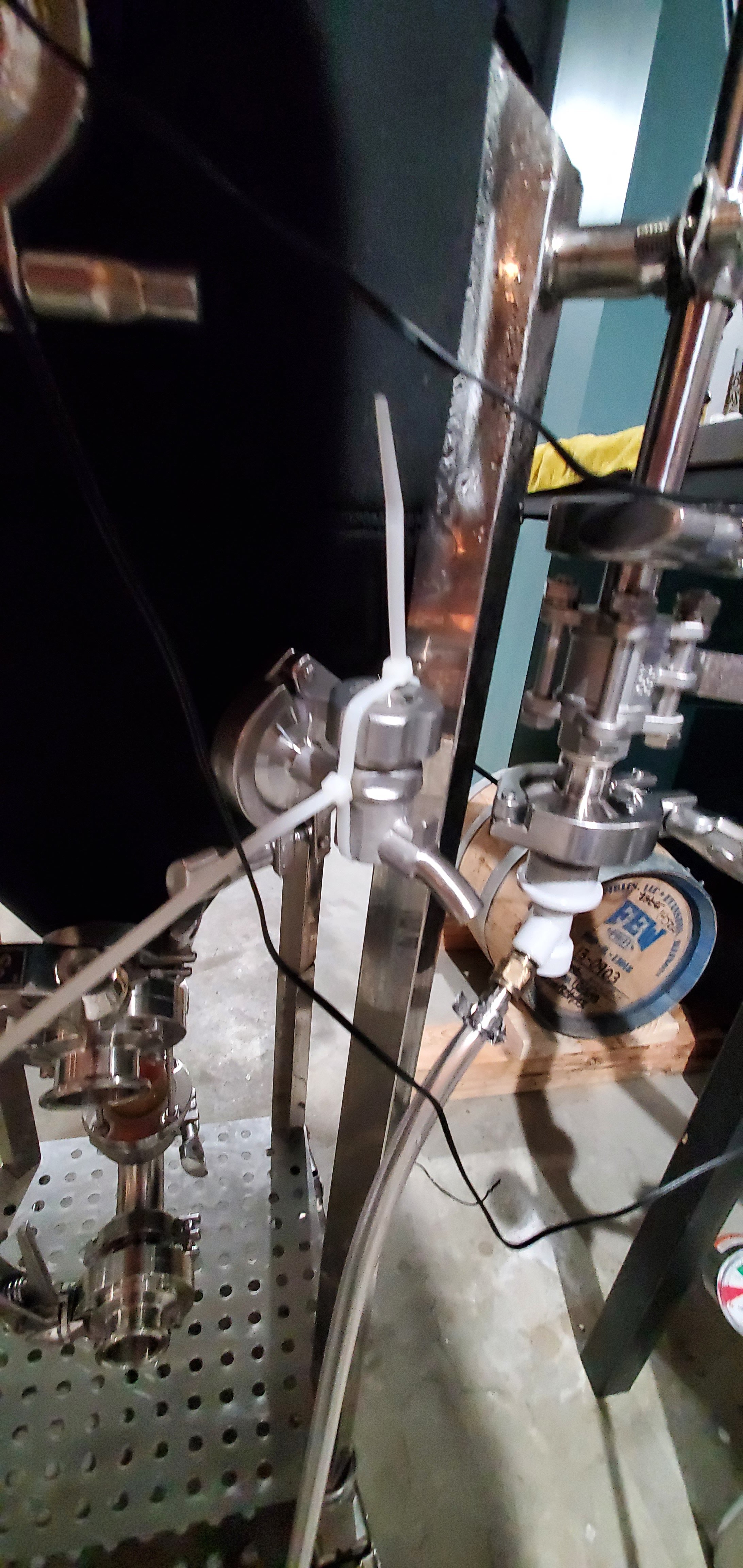

I grabbed a couple of zip ties and tied them around the sample valve as tight as I could. Stopped the leak.

Clearly something came loose. I'm guessing a gasket of some kind considering when I push down on the top of the valve, it feels squishy, like something is compressing.

Anyone had this happen?

Any idea what to look for our how to take this valve apart?

Thanks in advance!

After complete panic and losing an additional 40 oz on top of what I poured, I quickly depressurized the tank from 12 psi to 0 psi by opening the ball valve on the blow off cane, thinking that might help stop or slow the leak. It slowed it a bit, but not enough.

I plugged it with my thumb to give myself a minute to think. I started messing with the valve thinking of something was stuck, maybe I could jar it back in place. I ultimately got it to show down to a fast drip. Right around the same time, I realized if I put downward pressure on the top of the knob, it stops completely. So...

I grabbed a couple of zip ties and tied them around the sample valve as tight as I could. Stopped the leak.

Clearly something came loose. I'm guessing a gasket of some kind considering when I push down on the top of the valve, it feels squishy, like something is compressing.

Anyone had this happen?

Any idea what to look for our how to take this valve apart?

Thanks in advance!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)