You won't do better than to have @augiedoggie give you advice on this. He was very helpful to me when I was setting my system up, though it's pieced-together as opposed to having bought a complete system from a vendor like SSBt or Spike.

If money is an issue--and for whom is it not?--here are some ideas. It may not be the way you want to go, but it can give you an idea as to a different way to accomplish this.

I don't understand the "3-vessel" RIMS thing. I have a boil kettle, a mash tun, and a RIMS tube. No 3rd kettle for HLT, which I think is absolutely unnecessary. In fact, I think of that RIMS tube as my 3rd vessel.

I heat up my strike water in my BK. I then pump it over to the MT using my Riptide pump. I switch a couple hoses over, and then use that Riptide to recirculate through the RIMS tube. When it's time to lauter off the wort, I just pump it back to the BK. Can't imagine what a HLT would add to the equation--and I can't imagine what value the additional kettle and heating element brings. Already have a kettle w/ heating element.

*****

I built a control panel to handle the 5500-watt element in the BK. It's the eBIAB panel from Auber Instruments. (

Here is a list of their DIY panel kits). I don't do eBIAB, it was just a panel to control the element and the pumps, and potentially later on, use it to control a mash temp. I don't do that, but figured having a way to control pumps and such was a good idea. As you'll see, it isn't something I use any longer.

BTW, they have a new kit which combines the control of the BK element with a RIMS controller. I might have gone that direction if it had been available last summer....

Anyway, so I had this kit for the panel. I was able to put it together with a little assistance from here.

It's nice, including the keylock which when locked and key removed prevents a brewing buddy from deciding to turn on the element to see what happens.... :O

I think I have $450 into that. BTW, if you buy one of these, get the DIY wiring kit. It's not that expensive and will save you a lot of screwing around getting the right gauge wires and such. Wish it had been available when I bought mine....

*****

So then the RIMS. Bought the tube and controller and element from BrewHardware. It's in the neighborhood of $320 for it.

*****

I already had a 10-gallon Spike kettle. Had to add a few ports to it, including for the 5500-Watt element. I had a spare 10-gallon kettle a buddy had given to me. Had to add a couple ports to include camlocks, simply drilled the holes with a step bit and used the bulkhead fittings bobby at Brewhardware sells. They are as solid as welded, they're amazing.

*****

So--I had about $400 in the eBREW panel, another $320 in the RIMS. I had to add probably another....$80 in power cords to hook up the big element as well as the RIMS. (People always seem to forget the cords.

).

Just for the sake of argument, let's assume my BK and my MT are $400 apiece. They're cheaper, but that's high end. Both are 10-gallon. You could up that to 20 gallon if you wanted, just add the difference in price.

The Riptide is $200.

I use camlock fittings. I'm kind of a camlock junkie, I have a ton of them for every configuration. Figure $100 for camlocks and silicone hoses. Figure another $100 for additional camlock male and female connectors, $35 for a sight glass for the MT...

I have a very good counterflow chiller from Stout tanks. It's about $250 with shipping.

Add another $50 for other fittings and such, and $70 for the 5500-w element (brewhardware, again).

What does this all add up to?

If my math is correct, $2370. Maybe the bling factor is worth another couple/three grand, I don't know, but it's not to me.

****

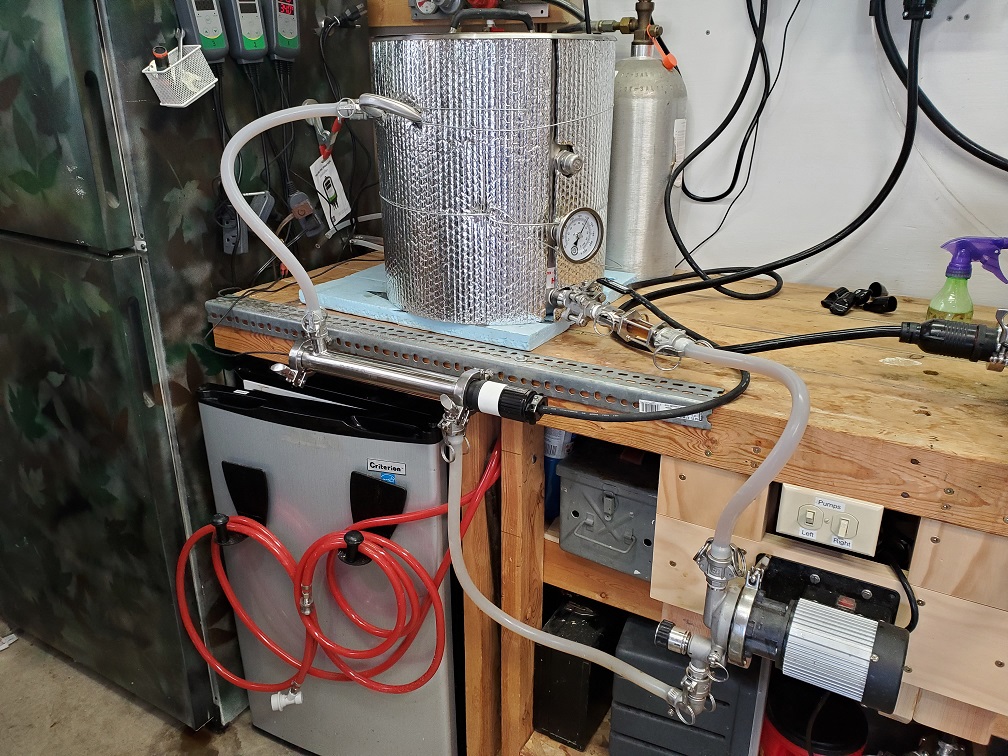

Maybe the stainless table is of value, I don't know. Mine is on a wooden bench. Here's a pic showing the setup. It took me a LONG time to finally figure out how to set it up to use a single pump and just move hoses back and forth. No plumbing, no hard-piping, and minimum wort losses.

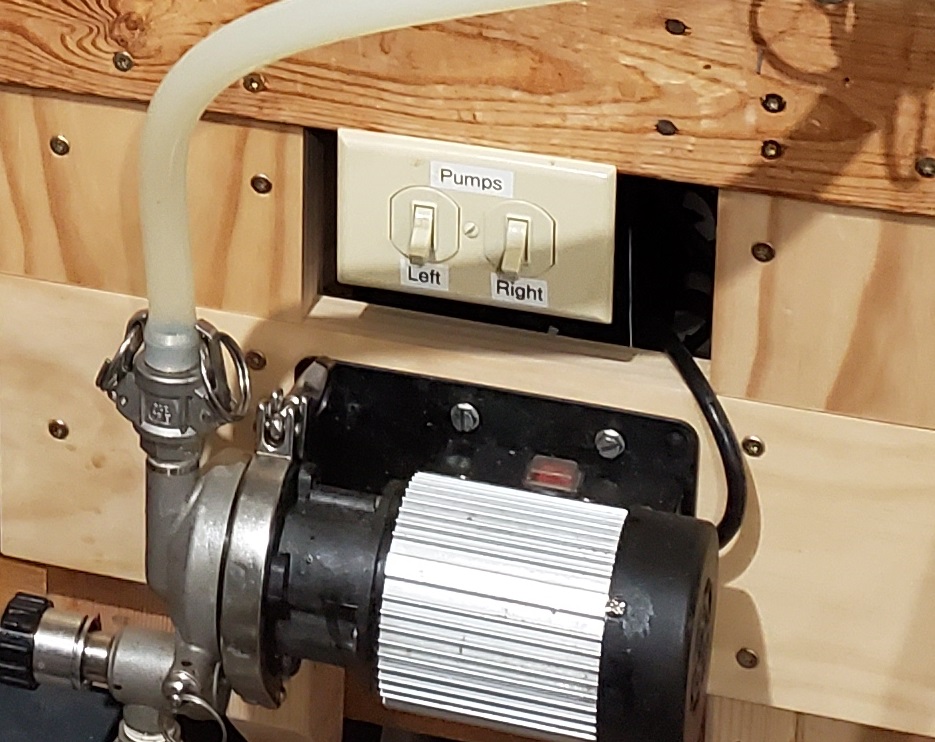

Further, I decided controlling the pumps from the wall panel was very inconvenient when I'm in a hurry to shut them off. So I hung the Riptide on the side of the bench with a couple of regular switches to control the Riptide and my Mark II which I use for cleaning the conical. (all this is plugged into GFCI outlets).

I brewed with this setup on Saturday; took me 5 hours from start to finish. That was pumping water into the BK, starting it heating, weighing out grain, etc. etc. There's only one pump so cleanup on that is easy (I recirc hot PBW solution through it and the BK, then rinse well with hot water).

I point all this out not because my way is the best way--it is for me, YMMV--but because it's a far lower cost approach than buying the ready-made setups from the big boys. I do have a conical fermenter (a Spike CF10), a Penguin glycol chiller, and it seems to me that I am able to afford those last two big-ticket items because I didn't sink $5000 into a system I could have for under $2500.

Here are some pics. The overall setup is the first one. You can see the Auber panel on the wall and next to it is the black RIMS controller. The RIMS controller plugs into a 20-amp 120v circuit, the Auber panel into a 30-amp 240-v receptacle just behind the fan on the right. Power cords are disconnected and looped over the top of the panels.

The closeup of the pump switches is the second. "Left" is the Riptide; "Right" is a Mark II pump I use to recirculate cleaning solution in my conical. Both switches are easy to get to. Both draw power from the CFCI receptacle that's left of the RIMS controller.

The third pic shows the hoses reconnected for the RIMS recirculation. The hose out of the bottom of the pump will be moved to the lower valve of the BK to pump the wort into that when the time comes. When that's done, that hose will be connected to the inlet of the counterflow chiller, and the hose at the top of the riptide will be connected to the lower valve on the BK.

Again, this works for me, your needs and wants may be different than mine. All I know is it took me about 9 months of diddling with pump locations, switches, hoses, and all that to end up here.

Good luck regardless; perhaps the above will give you some ideas, or even do the opposite, confirm what you already wanted to do.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)