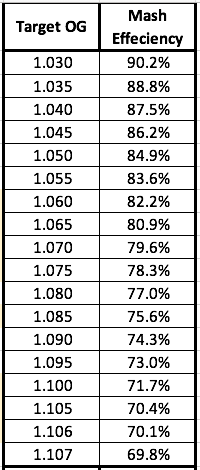

Does the size of the grain bill determine the recommended sparge time? Over the last two batches, Kolsch and IPA, I noticed a difference in the amount of sugars left in the MLT after reaching my BK volume. The Kolsch had final runnings out of the MLT of 1.009 SG and the IPA was 1.016 SG. Each sparge was right around 40 minutes (fly sparge) at 170 F. (5-gallon batch size, electric HERMS). Sparge methods were identical between the two batches.

I don’t necessarily feel like I need to troubleshoot this issue, rather I’d just like to better understand the relationship between the amount of grain in the MLT and the time taken to sparge to a consistent point; say 1.010 SG for example. Is this something that can be adjusted for in Beersmith?

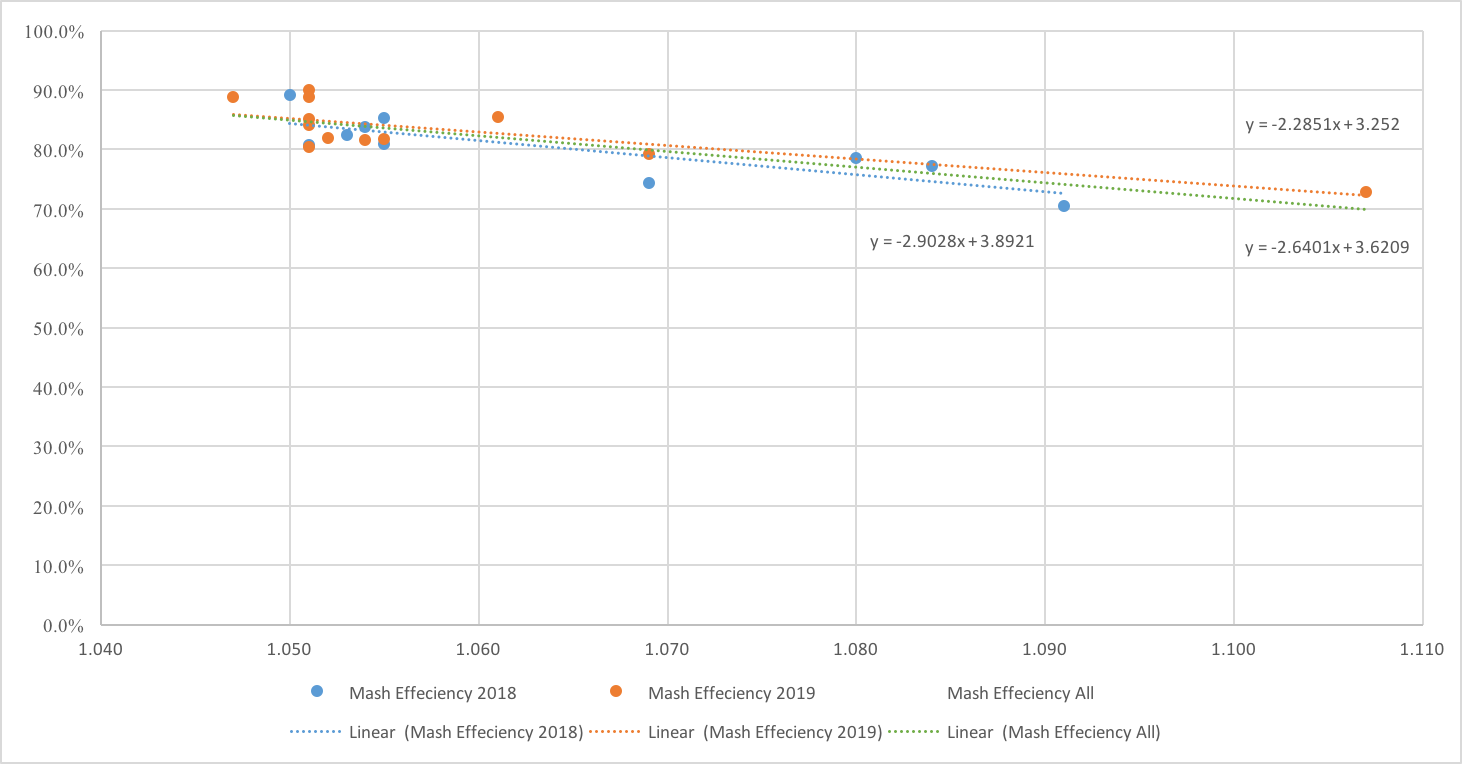

Perhaps an equipment profile could/should be created for different styles to account for slightly different volumes in the MLT? Begs the question; is there a significant difference in efficiency between large and small grain bills? Should my efficiency in my equipment profiles be lower for higher gravity brews? (Kolsch – eff. = 82%; IPA – eff. = 80%, for example)

I don’t necessarily feel like I need to troubleshoot this issue, rather I’d just like to better understand the relationship between the amount of grain in the MLT and the time taken to sparge to a consistent point; say 1.010 SG for example. Is this something that can be adjusted for in Beersmith?

Perhaps an equipment profile could/should be created for different styles to account for slightly different volumes in the MLT? Begs the question; is there a significant difference in efficiency between large and small grain bills? Should my efficiency in my equipment profiles be lower for higher gravity brews? (Kolsch – eff. = 82%; IPA – eff. = 80%, for example)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)