Soda Warrior

Member

- Joined

- Aug 16, 2019

- Messages

- 7

- Reaction score

- 0

I took it all apart last night. The side hole appears to be a relief hole, likely since the cartridges run fairly high at 850psi. As mentioned, in order of disassembly there are the following 4 parts: lockring, gasket, brass nozzle, plastic 1 way valve.

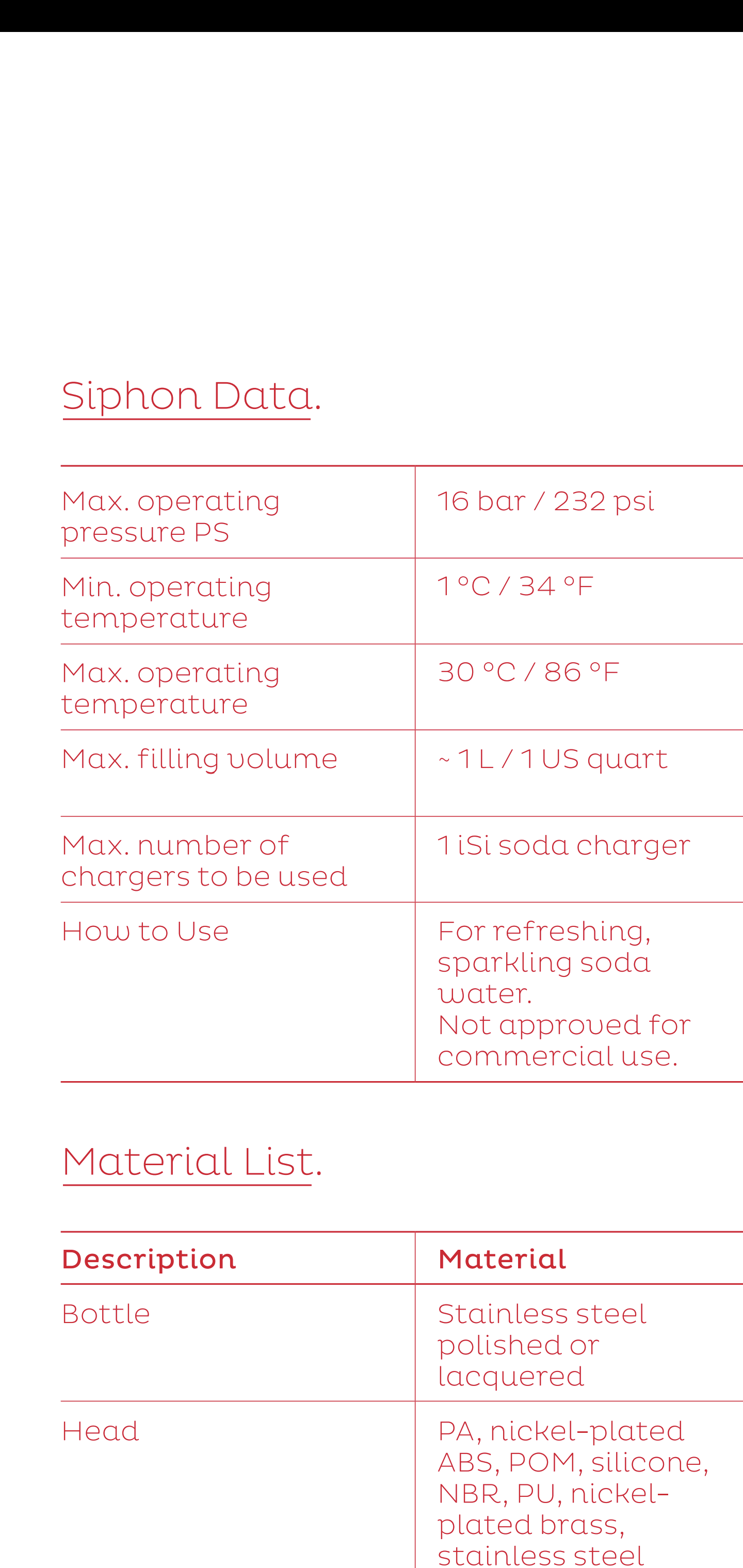

The innermost part is a plastic valve that lets gas thru into siphon, and does not let gas out. It is actuated by an outer rubberized sleeve that expands under pressure, allowing gas thru the side ports of the valve just under the sleeve. The 50psi pressure I run out of my tank may or may not be enough pressure to expand that rubber sleeve. If it is insufficient pressure, then I plan to run the siphon sans plastic valve, and just JB weld the relief hole. 50psi is likely not enough pressure to do any damage to any internal parts on the dispensing side of the siphon. I am away from the tank til Monday, and will run the test then.

I have done nothing further with the siphon, but just turned my regulator up to around 70psi (my regulator scale runs out at 60psi) and instead of running out of pressure, it dispensed all but around 40ml of the contents this time. I'd probably like to have higher carbonation and I think the siphon can take higher pressure, likely far, far more. It was good enough for my purposes. If you can turn up the pressure on your tank, I wouldn't alter the siphon, I don't think there's a need.

I am likely to buy a different pressure gauge to put on my regulator so I can measure higher pressures and experiment further. Can someone tell me the type of thread specification that these pressure gauges typically use, and any useful advice on fitting or pitfalls I should be aware of?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)