While I prefer the elimination of dedicated controls (Death to Controls?!?) I do think a physical E-Stop is prudent. Like above, I think having the E-Stop interrupt the high voltage feed makes good sense. Keep the LV stuff and controls powered so you can recover if needed. This does require two physical switches: one for main power and the E-Stop. This can be easily handled through a main contactor and contactors for elements and HV stuff (pumps, etc.). This is included in the example schematics we posted.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Batch Automated System

- Thread starter Paulaner

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Just out of interest (after seeing so many "kill" switch buttons in a gui) do any of you e-brewing BruControllers still have physical "disconnect everything NOW!" kill switches on your rigs?

Cheers!

That is one of the few things on the front of my control panel that still works. However, my control panel is in a hard to reach area. I do plan to make a small auxilary panel mounted by my touch screen that would have a hardware E-stop switch.

For now I would have to go outside the garage to kill it from the spa panel if such a need were to arise.

Good point. Nothing requires that E-Stop (or disconnect or whatever you choose to call it) be in/on your main panel. Our posted design in fact has the E-Stop, power, and optional LED's in a separate enclosure.

Paulaner

Well-Known Member

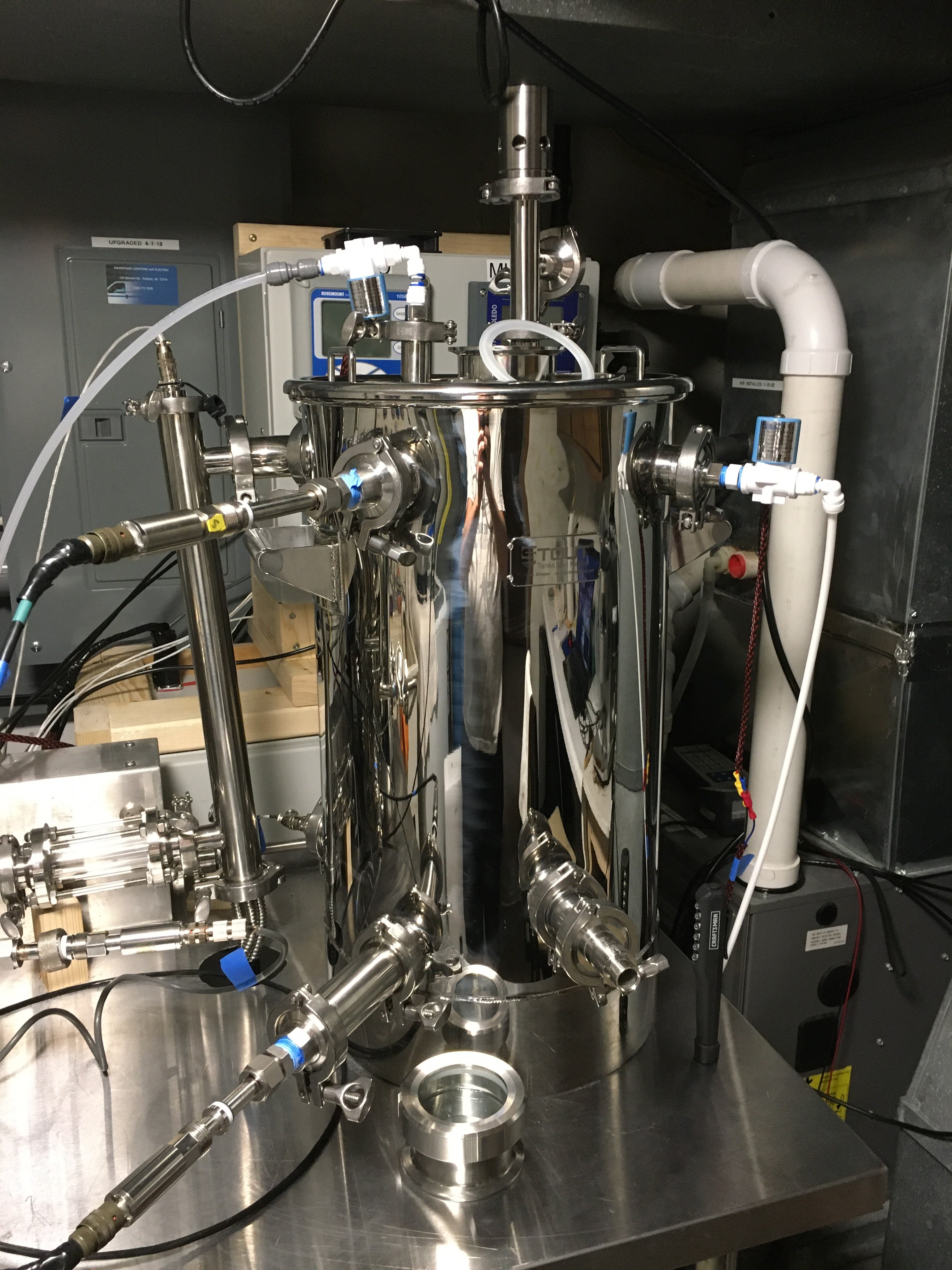

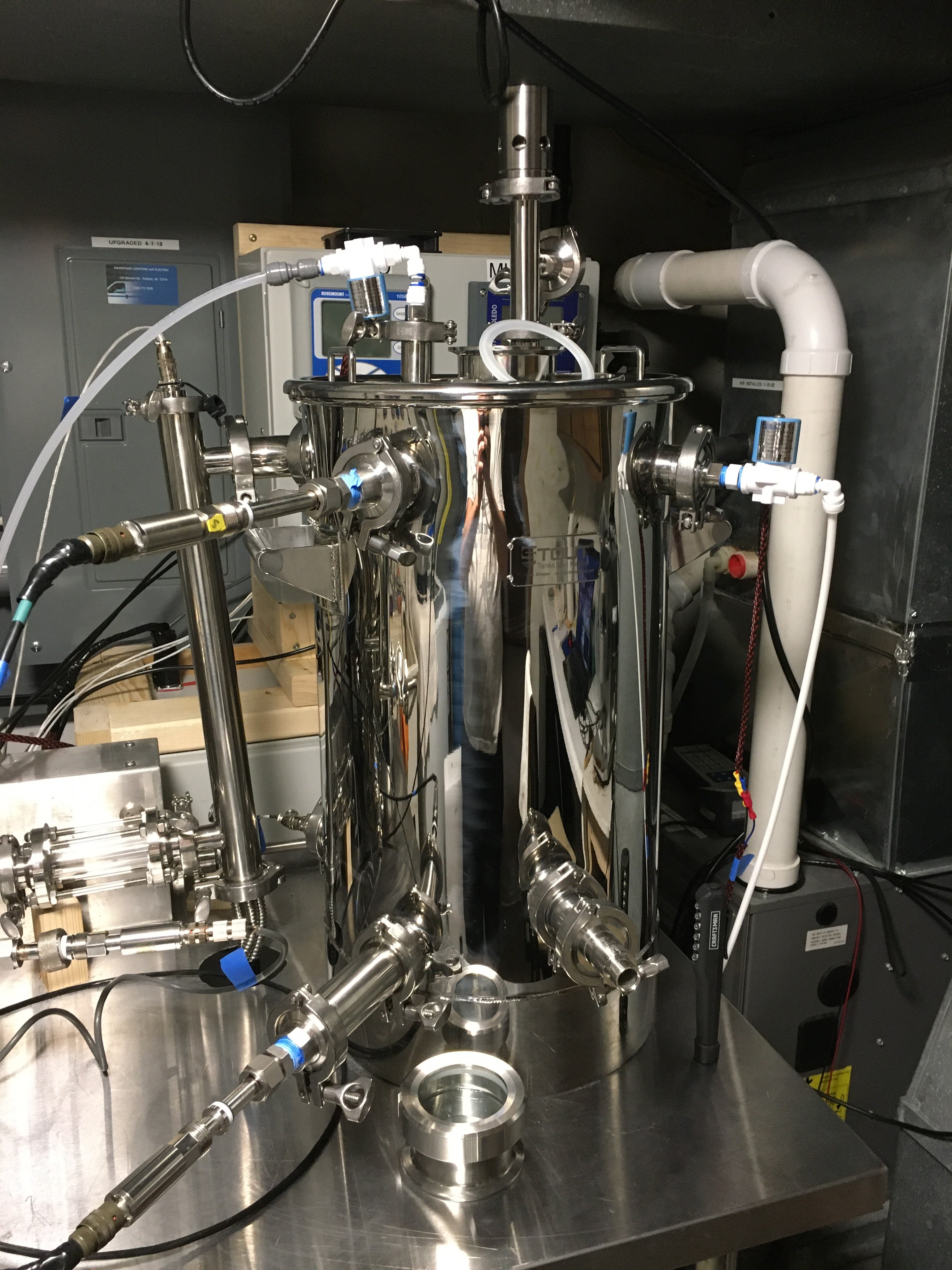

So its been a minute since I posted anything here, I've been slowly upgrading and adding to the setup over time. I added another spunding setup so I can spund two kegs at once along with dynamic pressure alarms so that if the average pressure shoots up or drops for whatever reason I'll get an alarm email. I then decided I needed another DO probe in the top of my MLT and what better reason to upgrade my transmitter while I was at it. Since I open the kettle to stir the mash after mash in, this has helped so that once I close everything back up I can automaticallypurge the headspace to keep the MLT o2 free.

I then finalized my CIP scripts with automatic kettle filling and draining with more ball valves. I also added a 3" sight glass to my MLT because why not. One item that has been on my list since I first saw Bryan's setup was auto sauergut dosing. All my components finally showed up so I finished my setup with scripting to automatically adjust and dose mash and boil PH. I've also almost finished with all of my scripts to automate everything and monitor everything to be notified if any problems present themselves I will now be notified of the problem.

My other project has been maximizing my RIMS setup. I will have to say that I'm truly impressed with the quadzilla element because it allows so much flexibility. I currently run all 4 elements which totals 5500watts at 25% so during the mash each element is capped at 344 watts each. There's currently 2 baffles in the tube and my mash is contained in a bag to prevent husk material on the element. I tried a few other percentages and wiring setups for the element but found some build-up on the element. Currently with how it's ran the element is almost pristine after the mash. I'd be willing to bet that some peoples HERMS systems have more build-up in the coil after the mash than what I'm seeing. Then when I run my CIP the element runs at 80% to heat up quickly. As for my final verdict on RIMS vs HERMS I'm still testing and experimenting with temps, flows, and percentages of power.

I then finalized my CIP scripts with automatic kettle filling and draining with more ball valves. I also added a 3" sight glass to my MLT because why not. One item that has been on my list since I first saw Bryan's setup was auto sauergut dosing. All my components finally showed up so I finished my setup with scripting to automatically adjust and dose mash and boil PH. I've also almost finished with all of my scripts to automate everything and monitor everything to be notified if any problems present themselves I will now be notified of the problem.

My other project has been maximizing my RIMS setup. I will have to say that I'm truly impressed with the quadzilla element because it allows so much flexibility. I currently run all 4 elements which totals 5500watts at 25% so during the mash each element is capped at 344 watts each. There's currently 2 baffles in the tube and my mash is contained in a bag to prevent husk material on the element. I tried a few other percentages and wiring setups for the element but found some build-up on the element. Currently with how it's ran the element is almost pristine after the mash. I'd be willing to bet that some peoples HERMS systems have more build-up in the coil after the mash than what I'm seeing. Then when I run my CIP the element runs at 80% to heat up quickly. As for my final verdict on RIMS vs HERMS I'm still testing and experimenting with temps, flows, and percentages of power.

Sweet rig, no doubt... no doubt. Glad to see you taking it to the next level!

But, I GOTTA SMASH THE LIKE BUTTON (is there a love button?) to hear your comments about the QuadZilla. I definitely don't yammer on about it because I don't want to come off like a shill, but I have been seeking at least the smallest shred of validation that RIMs can be properly implemented and be superior to HERMs. We aren't there, but this is a step. By the way... totally agree that using all elements at minimal power is the way to roll. Keep up the great work!

You hearing me, @Die_Beerery!?!

But, I GOTTA SMASH THE LIKE BUTTON (is there a love button?) to hear your comments about the QuadZilla. I definitely don't yammer on about it because I don't want to come off like a shill, but I have been seeking at least the smallest shred of validation that RIMs can be properly implemented and be superior to HERMs. We aren't there, but this is a step. By the way... totally agree that using all elements at minimal power is the way to roll. Keep up the great work!

You hearing me, @Die_Beerery!?!

Paulaner

Well-Known Member

After talking with Pete about the Quadzilla performance, I couldn't shake the idea of using a proportional ssr to lower the thermal stress on the wort even further. My goal through this endeavor is to keep the two vessel setup, while enjoying the low stress on the wort you can achieve with using three vessels. So far I'm quite satisfied, but I'm always trying to improve my end product. As of now, I would say that I'm pretty much there with the low stress that I'm shooting for as my wort srm's is quite low even with heavy Munich and caramalt grain bills, and the fresh grain flavors just pop out now. Hopefully, I'm getting closer to my end goal, but I still have a list of changes to try out, this is a long process as I only change one parameter per brew. Also, I gotta say thanks again to Pete for the help, I cannot recommend BruControl enough. I'm still amazed by how powerful this system is, if you can imagine something you want it to do, the system will do it. Here's my very expensive dimmer switch I had to get lol.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Are you testing both burst fire abs phase angle control modes?

Paulaner

Well-Known Member

Eventually yes, I'm starting out with phase angle, then once I have a feel for the results I'll try burst.

Burst is nicer on the electronics and will produce less noise but it limits resolution. It would have been nice if they included the half waves. If you don’t have any noise with PA, that’s probably the better route.

Last edited:

Great Thread. I am still planning on using a modified HERMS using a RIMS tube with the output connected to the Input of the outer tube of a Copper Counter flow chiller. I am planning on using a Quadzilla to initially heat the HERMS bath to a few degrees below the desired Mash and use the Quadzilla connected to a PWM Proportional Output and Controller (https://www.digikey.com/en/products/detail/sensata-crydom/PMP4850W/6827349)

I will control all 4 tubes.

Did you complete the Phase Angle or Burst Tests?

I will control all 4 tubes.

Did you complete the Phase Angle or Burst Tests?

Paulaner

Well-Known Member

I still have all intentions to, but I've been quite happy with phase angle, but am still adjusting it down to see how low I can go with my percentages. This takes quite a bit of time as I do an entire batch at one setting and then do the next one lower, and check the results in the final product. Once I get it all dialed in I'll eventually get to try the burst mode.

If PA is working... stick with it. No good reason then to use burst.

Similar threads

- Replies

- 43

- Views

- 2K

- Replies

- 0

- Views

- 415

- Replies

- 8

- Views

- 589

- Replies

- 11

- Views

- 1K

- Replies

- 11

- Views

- 1K