rosienej

Well-Known Member

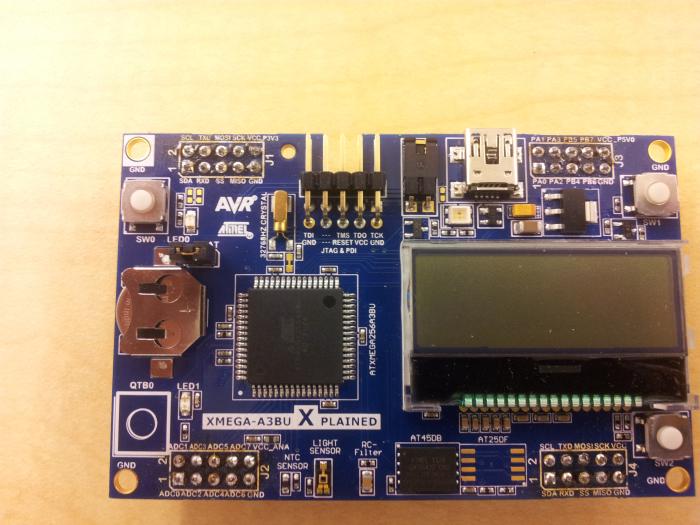

If you are going to attempt this, use IAR Embedded, the sample project compiles with no problem. The CSS project from TI is a bit messed... The IAR Embedded compile is very clean and easy. I will document the steps.

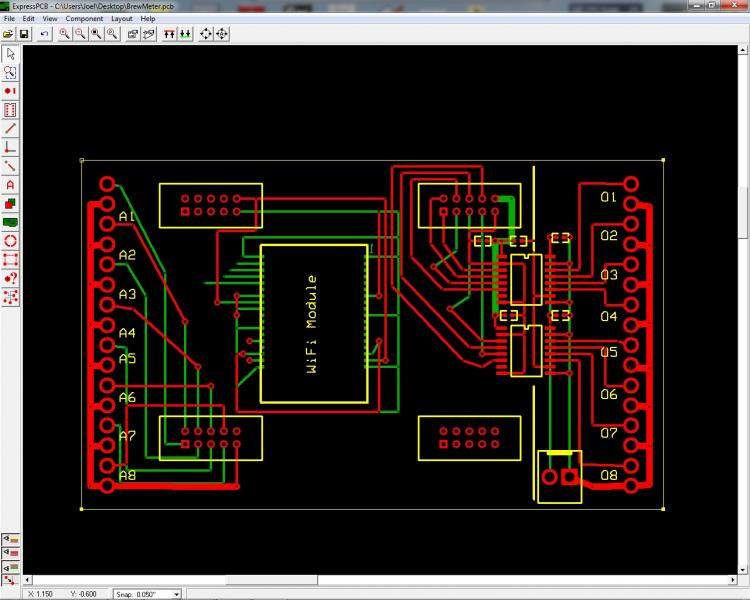

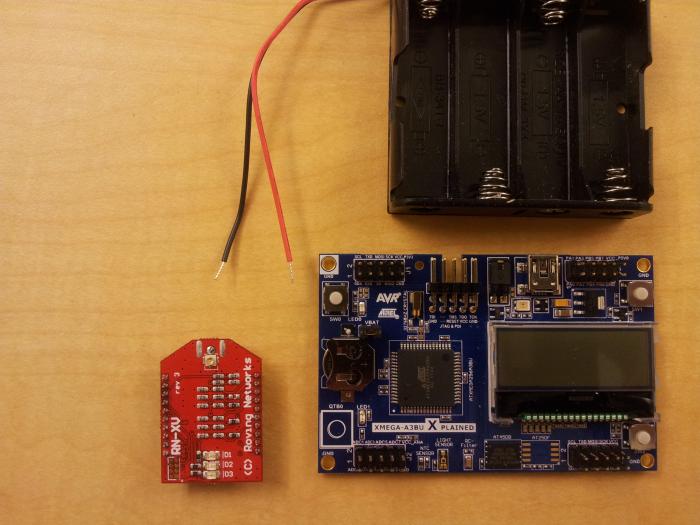

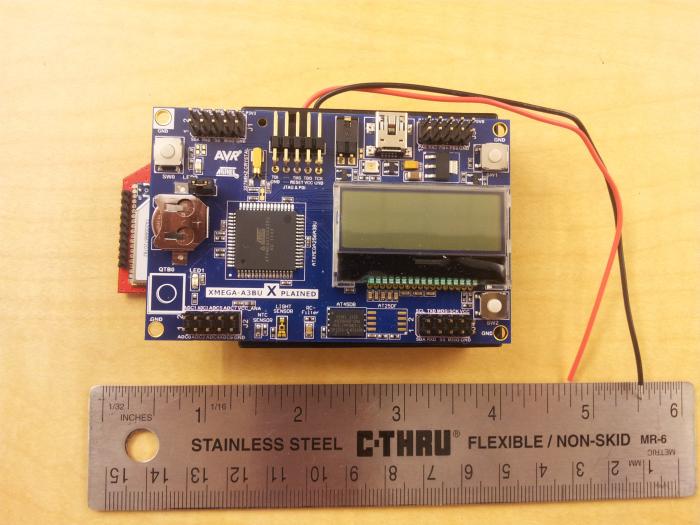

I need to test and calibrate the system, but the headless unit works!! On too the Wifi unit!!

Joel

I need to test and calibrate the system, but the headless unit works!! On too the Wifi unit!!

Joel

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)