mZnthebend

Well-Known Member

Very creative. What are the charcoal briquettes for?

Very creative. What are the charcoal briquettes for?

Is this something you can do over the phone? I mean, I don't have any of the stuff I need yet, but I plan to start looking for it. If I can find a fridge with the wiring diagram, I can scan it and post it for you. This would be an amazing addition to my setup. I just don't want to electrocute myself.

Probably condensation control.

Very, Very nice setup!!! I recently lost my old deep freezer's compressor and had to buy a new one that was smaller. I really miss the storage area of the larger one. My only concern about buying a used one is how long the cooling unit will last. Seeing as you are pretty handy with the inner workings of one, are they inexpensive to replace after going through all of this effort? I bet so, and I wish I had seen this thread a long time ago!!

Prost!

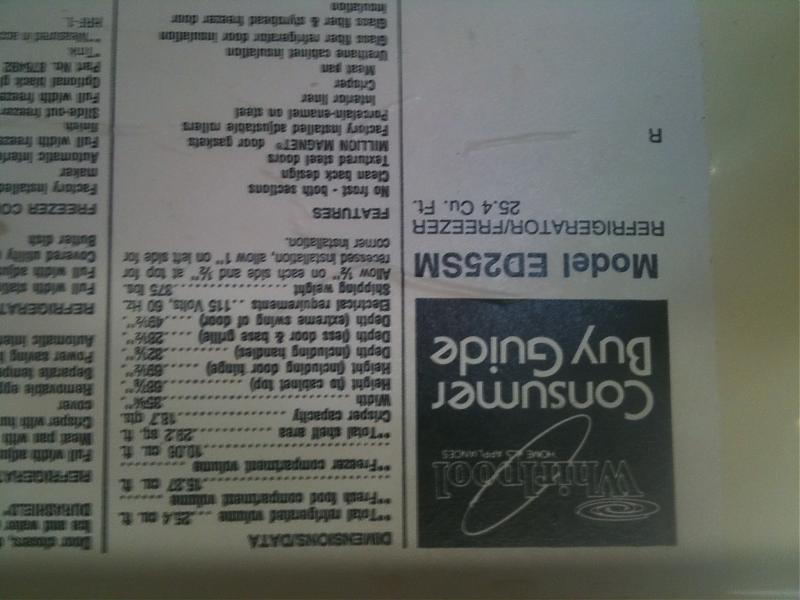

The challenge arises because side-by-side fridges (at least these kind, not Sub Zero or other top end brands) have only one compressor. All the cooling is done in the freezer and then the air is just allowed to flow into the fridge part through vents to keep it cool.

I thought about removing the center post as well. I think if you want to dot hat,t he best way to keep the seal in tact would be to put a stop plate on one of the doors. In other words, one of the doors would have a plate attached that allowed the second dorr to seal to it, the first door would be closed first, and the secnd door closed second to engage the sealing plate.

Does that make sense to you?

Using the wiring at the beginning of the thread, could I just use twist caps for the splices instead of the terminal block?

<------ knows nothing about wiring

I just saw your post. I really like that idea. Any luck with getting more info on how to make it happen?I am thinking of doing a conversion similar to the one you diagramed for cold on one side and warmer on the other (without cutting out the divider). My intent would be to use the cold side for pre-cooling/pre-carbonating cornies and/or lagering and to use the warm side to control ale fermentation in the summertime.

Can this be accomplished with one love controler that is set to come on to cool down the cold side (compresser) and set to come on to run a fan to cool the warmer side with a 120mm fan blown through the tube?

Any help would be appreciated on this. If I do this, I will certainly post a build thread.