You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your Kegerator

- Thread starter Flyin' Lion

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

christyle

Well-Known Member

Is all that hassle for the glycol tower really worth it? Does it collect condensation and drip on the kegerator a lot?

I personally like the look of this tower(aethetics wise) so to me its worth it, an air chilled one would not be sufficient to cool this type of tower. No condensation whatsoever, the towers cold to the touch but not so cold where it condenses. Just gotta make sure all the lines are wrapped correctly. All Wired up to flowmeters and RaspberryPints.

I personally like the look of this tower(aethetics wise) so to me its worth it, an air chilled one would not be sufficient to cool this type of tower. No condensation whatsoever, the towers cold to the touch but not so cold where it condenses. Just gotta make sure all the lines are wrapped correctly. All Wired up to flowmeters and RaspberryPints.

Whoa. This makes mine look silly and amateur. I need to up my game when I can afford it. Well done!

anthony914

Member

- Joined

- Sep 1, 2014

- Messages

- 6

- Reaction score

- 3

edit: added build thread link https://www.homebrewtalk.com/showthread.php?t=593107

Pretty standard but i love it

Lookin good, very similar to mine:

TwoHeadsBrewing

Well-Known Member

Album link: http://imgur.com/a/oQaye

More details in the imgur album, but here's a quick synopsis:

After having my kegs stuffed in a fridge with picnic taps, I decided it was time to build up a proper keezer. I already had kegs, lines, CO2 tank and regulator. So it was a relatively inexpensive project, aside from the freezer itself.

Here's the build list:

* Freezer - MagicChef 5.9 cu ft

* Temp Controller - Inkbird pre-wired (heat/cool)

* Taps - Perlick 301SS taps with 4" shanks

* CO2 - 4-way distribution manifold

* Collar - Inner box: 1x6" knotty pine. Outer: 1x6 walnut, Danish oil natural

* 1.5" insulation foam sheathing

* Aluminum tape

Already had:

* 5# CO2 tank

* Dual pressure regulator

* Beer and air lines, Corny kegs, ball lock connections, etc.

The build:

Most of the build was pretty straight forward. Make a box, drill some 7/8" holes in the box, etc. Adding the insulation foam was kind of a pain and got little foam pebbles ALL over the place. The aluminum tape really helped to keep the foam from breaking off inside the kegerator, and makes the rough cut edges look nicer. And on a functional side, should seal off air gaps and make cleanup easier.

I ended up picking up some blind nuts that have the same thread pattern as the taps. They were about 5 bucks on Amazon for 10. You simply drill a hole in whatever you want to make a tap handle out of and thread in the nut. I took some leftover pine and walnut scraps and glued them up. The nuts are a challenge to get in straight, which took a few tries.

The drip tray was a challenge, mostly because the drip tray itself was not perfectly square. I measured the tray and mistakenly assumed it would be square. But once I built the box it was obvious it bowed out a little on the sides. Some amount of cursing and smashing with a hammer later got it close enough. I attached the whole assembly to the front with construction adhesive after roughing up the paint with some sandpaper.

More details in the imgur album, but here's a quick synopsis:

After having my kegs stuffed in a fridge with picnic taps, I decided it was time to build up a proper keezer. I already had kegs, lines, CO2 tank and regulator. So it was a relatively inexpensive project, aside from the freezer itself.

Here's the build list:

* Freezer - MagicChef 5.9 cu ft

* Temp Controller - Inkbird pre-wired (heat/cool)

* Taps - Perlick 301SS taps with 4" shanks

* CO2 - 4-way distribution manifold

* Collar - Inner box: 1x6" knotty pine. Outer: 1x6 walnut, Danish oil natural

* 1.5" insulation foam sheathing

* Aluminum tape

Already had:

* 5# CO2 tank

* Dual pressure regulator

* Beer and air lines, Corny kegs, ball lock connections, etc.

The build:

Most of the build was pretty straight forward. Make a box, drill some 7/8" holes in the box, etc. Adding the insulation foam was kind of a pain and got little foam pebbles ALL over the place. The aluminum tape really helped to keep the foam from breaking off inside the kegerator, and makes the rough cut edges look nicer. And on a functional side, should seal off air gaps and make cleanup easier.

I ended up picking up some blind nuts that have the same thread pattern as the taps. They were about 5 bucks on Amazon for 10. You simply drill a hole in whatever you want to make a tap handle out of and thread in the nut. I took some leftover pine and walnut scraps and glued them up. The nuts are a challenge to get in straight, which took a few tries.

The drip tray was a challenge, mostly because the drip tray itself was not perfectly square. I measured the tray and mistakenly assumed it would be square. But once I built the box it was obvious it bowed out a little on the sides. Some amount of cursing and smashing with a hammer later got it close enough. I attached the whole assembly to the front with construction adhesive after roughing up the paint with some sandpaper.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

Scout

Well-Known Member

Some really nice stuff in here, I'm just trying to decide whether to go with a kegerator or a keezer.

dreaded_rust

Well-Known Member

- Joined

- Jan 6, 2015

- Messages

- 226

- Reaction score

- 51

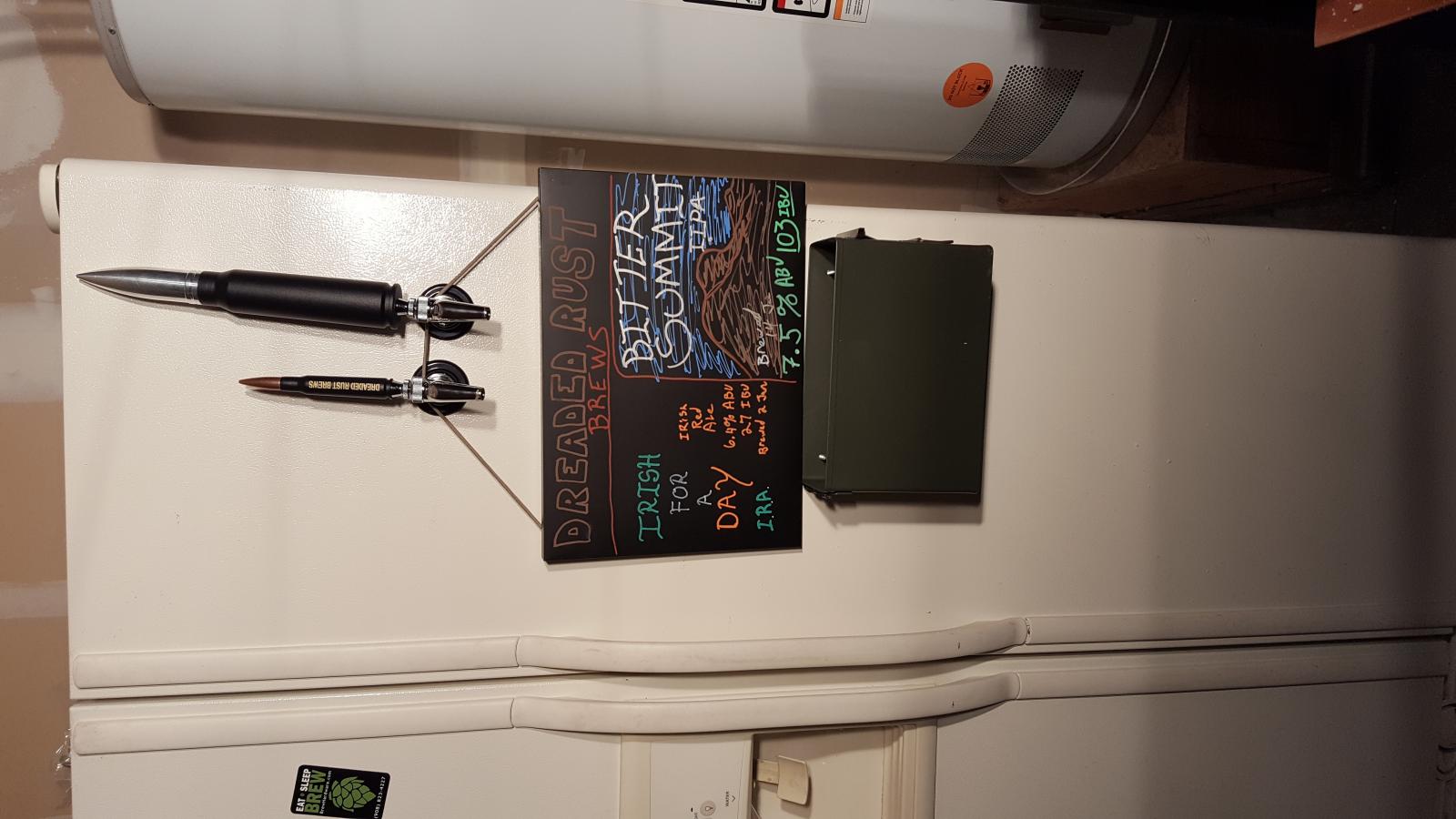

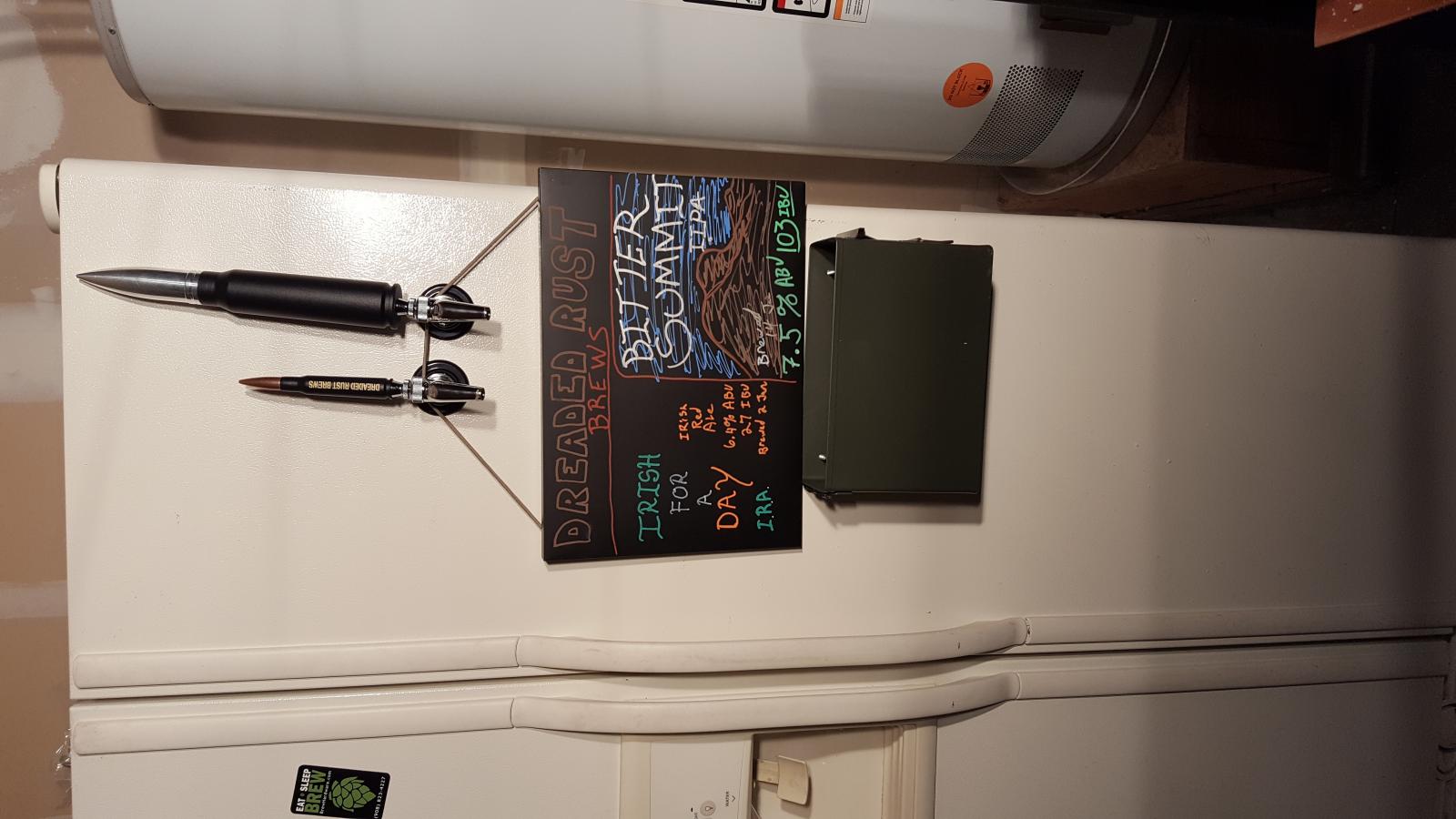

Finally got around to putting together the keggerator!!! So excited to finally be posting in this thread.

I had both beers flowing great after a pint or two of foam.

The handle on the left is a .50 cal and the one on the right is a 30 mm. Went with a bit of a military theme cause my wife and I are both military (she's lucky enough she actually gets to work with the 30 mm)

I'm blown away how great the IPA tastes being so fresh.

I still need to clean up the lines a bit and build a wooden shelf to set the kegs on.

Cheers!

I had both beers flowing great after a pint or two of foam.

The handle on the left is a .50 cal and the one on the right is a 30 mm. Went with a bit of a military theme cause my wife and I are both military (she's lucky enough she actually gets to work with the 30 mm)

I'm blown away how great the IPA tastes being so fresh.

I still need to clean up the lines a bit and build a wooden shelf to set the kegs on.

Cheers!

evilleadam

New Member

- Joined

- Nov 20, 2012

- Messages

- 4

- Reaction score

- 3

Danby Designer DCR044A2BDD

Mini Fridge Keggerator Build

This build is still in progress, but I thought I'd share my process thus far for those looking to modify a similar model mini fridge.

Mini Fridge Keggerator Build

This build is still in progress, but I thought I'd share my process thus far for those looking to modify a similar model mini fridge.

evilleadam

New Member

- Joined

- Nov 20, 2012

- Messages

- 4

- Reaction score

- 3

Thanks. I'm not sure yet how I will proceed. I'm fine with just opening the door for a pint for now. But, I must say, there is a lot to be said for the aesthetics of a nice draft tower!

I changed this fridge I got off Craigslist to a kegerator for a few years. View attachment ImageUploadedByHome Brew1487646128.207667.jpg

Last year I had to redo my entire basement due to a leak 🙄 as a result I changed it to this layout with the fridge on the other side... I guess it was worth it in the long run View attachment ImageUploadedByHome Brew1487646405.515939.jpg

Last year I had to redo my entire basement due to a leak 🙄 as a result I changed it to this layout with the fridge on the other side... I guess it was worth it in the long run View attachment ImageUploadedByHome Brew1487646405.515939.jpg

CGVT

Senior Member

I changed this fridge I got off Craigslist to a kegerator for a few years. View attachment 389835

Last year I had to redo my entire basement due to a leak 🙄 as a result I changed it to this layout with the fridge on the other side... I guess it was worth it in the long run View attachment 389836

Nice on both counts!

Grinnan5150

Well-Known Member

Just a standard Kegco keggerator. I would like to build something but not that handy and don't have a lot of time so this will have to do. Just got it set up and have my first keg carbing up now.

Noticed that the beer connector slowly leaks out the top so it's either the connector or the small dent in the post. Either way it will work, just need to disconnect it every time I pour a glass. I'll fix it eventually.

Noticed that the beer connector slowly leaks out the top so it's either the connector or the small dent in the post. Either way it will work, just need to disconnect it every time I pour a glass. I'll fix it eventually.

IndyBlueprints

Well-Known Member

I built mine into the basement cabinets. Counter-top is a bit crowded at the moment, with the fermenting and what-not going on.

The Co2 tank is in the cabinet under the sink.

Put the cabinet face on a piano hinge:

The Co2 tank is in the cabinet under the sink.

Put the cabinet face on a piano hinge:

This is my current setup that I just got in Jan. 2017.

The 5G Carboy is my Lager. Should be done at the end of March.

The Keg inside is Soda Water.

The Keg on the side of the Kegerator is a Wee Heavy Scottish Ale I kind of just created myself, so I don't know how it is going to taste.

I racked it onto 3.3lbs of sweet cherry puree and now it is just sitting in the Keg until the end of March.

The 5G Carboy is my Lager. Should be done at the end of March.

The Keg inside is Soda Water.

The Keg on the side of the Kegerator is a Wee Heavy Scottish Ale I kind of just created myself, so I don't know how it is going to taste.

I racked it onto 3.3lbs of sweet cherry puree and now it is just sitting in the Keg until the end of March.

badassdrunkenpanda

Member

- Joined

- Oct 23, 2014

- Messages

- 13

- Reaction score

- 6

Taking some inspiration from the the amazing builds in the thread, I finished my 4 tap keezer. Just need to work on a taplist display.

CGVT

Senior Member

Very nice!

Taking some inspiration from the the amazing builds in the thread, I finished my 4 tap keezer. Just need to work on a taplist display.

Awesome looking keezer!

Did you build your 4 tap tower, or buy that? If you built it did you drill out the pipe caps to allow for the faucet shanks or buy those?

I am looking to do something very similar for my new keezer.

badassdrunkenpanda

Member

- Joined

- Oct 23, 2014

- Messages

- 13

- Reaction score

- 6

Bought it. 2" pipes all the way around, then used a 2"-1-1/2" bushing, and attached a 1-1/2"-3/4" bushing (reduced the 2" hole to a 3/4" hole). The shank was put through and the nut fit into the smaller bushing as I screwed it in.

Bought it. 2" pipes all the way around, then used a 2"-1-1/2" bushing, and attached a 1-1/2"-3/4" bushing (reduced the 2" hole to a 3/4" hole). The shank was put through and the nut fit into the smaller bushing as I screwed it in.

did you get it from the guy on Etsy, or find it somewhere else?

badassdrunkenpanda

Member

- Joined

- Oct 23, 2014

- Messages

- 13

- Reaction score

- 6

Hhmm... might've misinterpreted your question. I built the keezer, bought the pipe tower parts from home hardware and assembled it myself. There are some towers in this thread that were machined to spec, and I thought you were asking if I had machined the parts myself.

Hhmm... might've misinterpreted your question. I built the keezer, bought the pipe tower parts from home hardware and assembled it myself. There are some towers in this thread that were machined to spec, and I thought you were asking if I had machined the parts myself.

Sorry should have been a bit clearer with my questions.

I was wondering if you built the tower or bought it, but mostly was wondering if you had to use a special adapter to mount the taps in the pipe.

Sounds like it is all off the shelf parts.

There is a guy on Etsy that is making these and machining and finishing them and selling for $$$. I like the idea of DIY'ing it.

badassdrunkenpanda

Member

- Joined

- Oct 23, 2014

- Messages

- 13

- Reaction score

- 6

Sorry should have been a bit clearer with my questions.

I was wondering if you built the tower or bought it, but mostly was wondering if you had to use a special adapter to mount the taps in the pipe.

Sounds like it is all off the shelf parts.

There is a guy on Etsy that is making these and machining and finishing them and selling for $$$. I like the idea of DIY'ing it.

Lol, I built it myself with off the shelf parts. I did not use a special adapter to mount the taps to the pipes. The nut that came with the shanks is what I used. It fit into the space of the smaller bushing, and I was able to tighten it. Everything on the keezer was off the shelf products and I DIY'ed it together.

Craghunter

Active Member

Here is mine... I just need more beer

Pretty standard 2-tap Edgestar. I like it, but the taps stick if you don't use them everyday

If your kegerator was at house, you'd never have to worry about the faucets sticking...

CGVT

Senior Member

Very nice!

Not quite a kegerator this one. Uses two jockey boxes and pretty mobile. I built it for my daughter's wedding, now she wants a couple smaller ones. She's going to use them in her new wedding planner business.

Edit- posting from a phone, I see one pic but attachments I have to click on. Not sure what you are seeing.

Cheers!

View attachment 392881

View attachment 392882

View attachment 392883

View attachment ImageUploadedByHome Brew1489641521.411677.jpg

Edit- posting from a phone, I see one pic but attachments I have to click on. Not sure what you are seeing.

Cheers!

View attachment 392881

View attachment 392882

View attachment 392883

View attachment ImageUploadedByHome Brew1489641521.411677.jpg

Stillraining

Well-Known Member

Nice Job Dan!

Thank you brother. It was a truly satisfying, fun build. I want to make a regular kegerator with the same cedar plank.

Eigenbrau

Well-Known Member

It's funny, I posted a kegerator in this same thread years ago. I've since upgraded a bit. I made the tap handles myself. I've had a few people comment on how stupid it is to have vacuum tubes as tap handles, but I haven't had an issue yet in the 6 months I've had this built. Perlicks don't require a substantial amount of force to open, which I think is the saving grace.

The cask system isn't quite set up just yet, it's next on my list.

The cask system isn't quite set up just yet, it's next on my list.

lpdjshaw

Well-Known Member

Love the beer engine!!

Eigenbrau

Well-Known Member

Love the tap handles!!!!!

Are they just raw tubes mounted into a base? Or did you release the vacuum and fill them with acrylic or something?

They still have their vacuum. I experimented with releasing it, but broke a couple in the process and figured it wasn't worth it. They're epoxied into a socket and the socket epoxied to a nut I picked up at Lowe's. There were some concerns initially, but they really don't see enough abuse to cause a problem. It's not to say an accident couldn't happen someday.

They still have their vacuum. I experimented with releasing it, but broke a couple in the process and figured it wasn't worth it. They're expoxied into a socket and the socket epoxied to a nut I picked up at Lowe's. There were some concerns initially, but they really don't see enough abuse to cause a problem. It's not to say an accident couldn't happen someday.

As a Klipsch owner....love it. Horns and tubes go hand in hand. Would love to add a SET amp to my stereo one day.

RevKev

Well-Known Member

Converted my two tap tower to three a while back. Just basic a Haier kegerator

View attachment 1490505670836.jpg

View attachment 1490505824375.jpg

View attachment 1490505670836.jpg

View attachment 1490505824375.jpg

Here's mine

Westinghouse WRM1300WC

Just fits four 9.5l kegs (should fit two big ones up front too).

Intertap faucets.

Managed to keep the door stock and even one of the shelves fits in there for yeasties and the odd bottle.

The 12V line for the fan, the STC2000 sensor, and the CO2 run out through the drain hole in the back. CO2 distribution is under the bottom shelf.

Westinghouse WRM1300WC

Just fits four 9.5l kegs (should fit two big ones up front too).

Intertap faucets.

Managed to keep the door stock and even one of the shelves fits in there for yeasties and the odd bottle.

The 12V line for the fan, the STC2000 sensor, and the CO2 run out through the drain hole in the back. CO2 distribution is under the bottom shelf.

brewtodrinktobrew

Active Member

My keezer build.

Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 25

- Views

- 1K

- Replies

- 2

- Views

- 278

Latest posts

-

-

-

-

-

-

-

-

For Sale SS Brewtech - 7 Gallon Unitank 1.0

- Latest: IslandLizard

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)