You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your element housings/pots. How did you do it?

- Thread starter Boerderij_Kabouter

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ihearthops

Well-Known Member

Here's mine -- similar to what others have done. Plastic gang box with the element cord grounded to the keg skirt. JB Weld holds the box on the keg -- element can be removed/replace very easily.

That looks nice!

Is there a piece of sheet metal between the box and the element? I wonder why you needed that. Would it not be possible to attach the box directly to the element?

ihearthops

Well-Known Member

I originally wanted to, but there isn't enough thread depth on the element -- only option was to cut the hole bigger on the gang box and mount it flush to the keg, stock element gasket on the outside.

ihearthops

Well-Known Member

I originally wanted to, but there isn't enough thread depth on the element -- only option was to cut the hole bigger on the gang box and mount it flush to the keg, stock element gasket on the outside.

Sorry -- just realized I didn't completely answer your question.

No, there is no sheet metal in between the gang box/element/keg -- it's just the keg wall.

No, there is no sheet metal in between the gang box/element/keg -- it's just the keg wall.

I see now, thanks. My vision was influenced by what I was planning to do. I was going to use a round PVC fitting that slips over only the plastic part of the element and is JB welded on top of the metal part of the element. After seeing yours, and a few other box installations, I am considering to use a box as well. I think the hole could be cut snug around the plastic part to avoid a leakage path into the box. Your method has the benefit of easy element replacement though. I will experiment with this a bit.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

ihearthops

Well-Known Member

I see now, thanks. My vision was influenced by what I was planning to do. I was going to use a round PVC fitting that slips over only the plastic part of the element and is JB welded on top of the metal part of the element. After seeing yours, and a few other box installations, I am considering to use a box as well. I think the hole could be cut snug around the plastic part to avoid a leakage path into the box. Your method has the benefit of easy element replacement though. I will experiment with this a bit.

Another thing to note...

To mitigate the risk you mention of potential leakage into the box, I drilled a ~1/4" hole in the bottom of the box to act as a drain port in the event of any leak. I figured in theory there could never be enough buildup of water (from a leak) that would ever allow the water level to rise to the point of the terminals -- plus I find myself checking to see if I have any leaks periodically throughout my brew day. I was super paranoid about that, so it keeps me at peace rather than have to worry about killing myself for a batch of beer. :cross:

trscstghst

Member

so really all there is to it is getting a heating element and hooking up the wires?(of course making sur you have a heat resistant and watertight fitting) im assuming that you could do the same thing with a cooler?, eliminating the need for aluminum or ss pots

I know this was asked already but I'd like to hear a few more answers. So whenever you guys want to move/lift and dump your keggle you have to drag those cords around? Or is the dangling cord no biggie.

I don't have 220v so I'd need to mount two 2000watt elements in mine. I don't know if I should do one box or two. I just had a heat stick fail and pop my gfci so I'm considering mounting them now.

I don't have 220v so I'd need to mount two 2000watt elements in mine. I don't know if I should do one box or two. I just had a heat stick fail and pop my gfci so I'm considering mounting them now.

samc

Well-Known Member

Several of the builds show that the cord is plugged into the box housing the element. Unplug and no cord to drag around.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Another thing to note...

To mitigate the risk you mention of potential leakage into the box, I drilled a ~1/4" hole in the bottom of the box to act as a drain port in the event of any leak. I figured in theory there could never be enough buildup of water (from a leak) that would ever allow the water level to rise to the point of the terminals -- plus I find myself checking to see if I have any leaks periodically throughout my brew day. I was super paranoid about that, so it keeps me at peace rather than have to worry about killing myself for a batch of beer. :cross:

This is a good idea....I'd drill 2 holes in the bottom so you can relieve pressure. If the box is completely sealed, it may not drain through just one hole because the vacuum will prevent the fluid from draining.

I know this was asked already but I'd like to hear a few more answers. So whenever you guys want to move/lift and dump your keggle you have to drag those cords around? Or is the dangling cord no biggie.

I don't have 220v so I'd need to mount two 2000watt elements in mine. I don't know if I should do one box or two. I just had a heat stick fail and pop my gfci so I'm considering mounting them now.

My HLT and BK both unplug from my control panel, leaving a minor length of cord attached, but that isn't an issue at all since I clean in place. My CIP cycle consists merely of circulating hot water and PBW, then rinsing with cold water. The only vessel I remove from the stand is my MLT, which isn't plugged into anything. Even the MLT is easy to clean, with dumping the grain out, disassembling the false bottom, then giving it a good rinse.

This is just my experience, and how I do it, but I'm happy with it.

TB

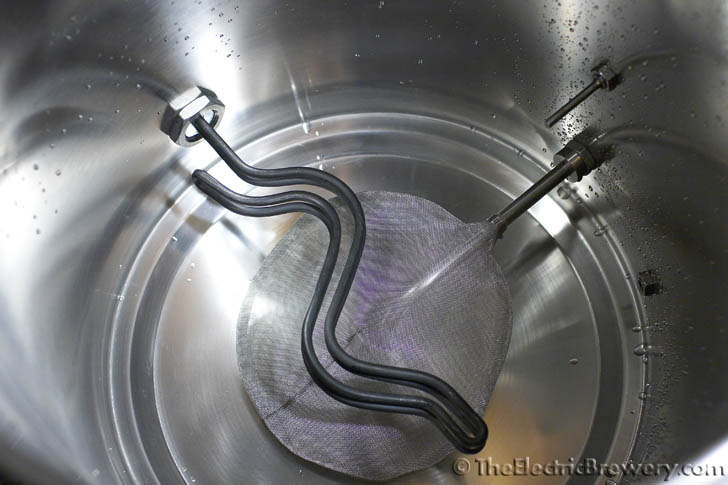

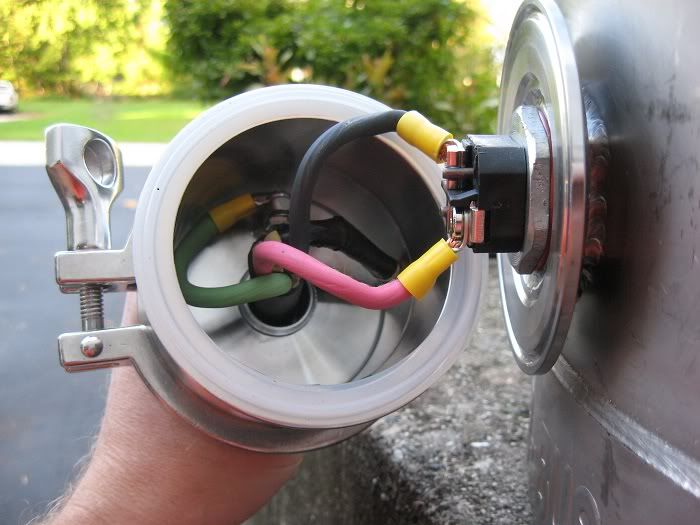

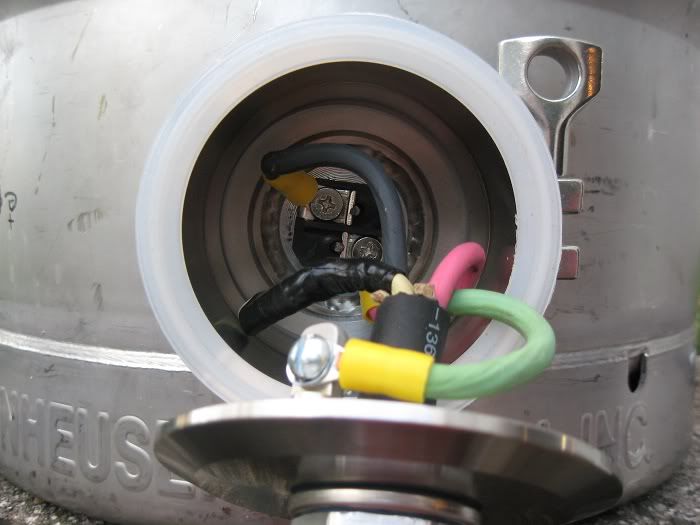

this is my electrical connection---1 inch stainless lock nut on the inset of the keggle, holding element (+gasket).

The rubber housing is a 1 1/2 inch plumbing connection, clamped on with the hose clamps. The ground wire is just visable, clamped across the element nut.

The power cord goes through a drilled PVC cap that clamps down on it when the hose clamp is tight.

t

kal

Well-Known Member

I know this was asked already but I'd like to hear a few more answers. So whenever you guys want to move/lift and dump your keggle you have to drag those cords around? Or is the dangling cord no biggie.

My HLT and BK disconnect at the control panel with a 6 foot cord each:

My HLT (and most HLT's) doesn't need cleaning. Only contains water. So it never gets moved.

My BK simply gets titled 90 degrees into the large sink right beside it for a scrub after brewing.

The pre-wash arm goes a great job at getting most of the stuff out and then a quick wipe with a sponge to clean the element is all that is needed.

Kal

this is my electrical connection---1 inch stainless lock nut on the inset of the keggle, holding element (+gasket).

The rubber housing is a 1 1/2 inch plumbing connection, clamped on with the hose clamps. The ground wire is just visable, clamped across the element nut.

The power cord goes through a drilled PVC cap that clamps down on it when the hose clamp is tight.

t

While there are many great methods here, I wanted to compliment you on the simplicity and effectiveness of this one. I will be replicating it. Thanks:rockin:

sjvicker

Well-Known Member

I did the basically the same thing as most of you and placed the O-ring between the plastic box and the welded fitting.

For future reference, it takes a 1-1/4" hole to fit the electrical element.

For future reference, it takes a 1-1/4" hole to fit the electrical element.

I may go this route, using some insulating sleeve inside, and drilling some drain holes, thanks Ihearthops. I have a cheapo element wrench socket from Loew's, so replacing the element would not be a problem. This would be welded to the keg around the one inch element bung, because you can never have enough triclamps!

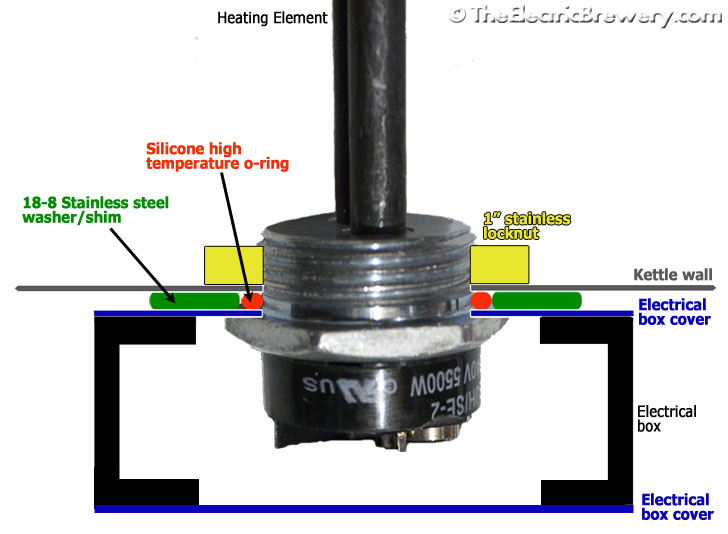

How to attach the elements to our Blichmann kettles in a safe and secure manner took some thinking. I spent many months on this. We wanted the entire kettle to be electrically grounded for safety reasons the same way any power tool or appliance chassis is grounded.

Grounding means that the entire metal chassis (in this case the entire kettle) is connected to your house's electrical system ground plane. This ensure that any stray current can find its way to ground instead of through something else (such as the brewer!) in the off chance that something goes wrong and one of the 'hot' wires becomes disconnected and touches the kettle. Without proper grounding the kettle would instead simply become energized and pose a great danger to the brewer. A proper electric brewing setup should always have everything properly grounded!

I also don't want any wires exposed as they could be easily damaged. Kettles are heavy and moving them around while you clean them means the brewer will inadvertently bump parts sticking out against other things. No matter how careful you are, it will happen. I wanted the wires to be protected as much as possible and completely covered up.

So I stole ideas from how Blichmann does weldless fittings and came up with this:

Complete instructions with parts list is here: http://www.theelectricbrewery.com/heating-elements

Kal

Kal,

What did you use to seal the 3/4" hole in the box opposite the one you installed your cord in?

Thanks.

kal

Well-Known Member

2-gang boxes come with screw in plugs. My 2-gang boxes had 4 holes.What did you use to seal the 3/4" hole in the box opposite the one you installed your cord in?

You can see one of the plugs below the cord grip in this picture:

Kal

2-gang boxes come with screw in plugs. My 2-gang boxes had 4 holes.

Kal

Aaaaaaah. That was too obvious for me, I guess. The best place to hide those screw in plugs from me is apparently in the box.

Many thanks. I should have this done in time to brew a nice english brown this weekend.

Thanks, Kal.

great thread! Subscribed!

BeerCanuck

Well-Known Member

I was researching an EHLT I am planning to build and found this thread.

Awesome

Awesome

Junkster

Well-Known Member

Mine is a SS lock nut welded onto a tri-clover cover plate. The element threads into that and the cover is simply a 1-1/4" PVC ell into which I made some cuts on the table saw. This makes slightly flexible "fingers" which grip the wrench flats of the element by way of the hose clamp. The cord end of the cover is a threaded bushing glued in and a 3/4" cable clamp screwed into that. The whole thing is easily removed for cleaning.

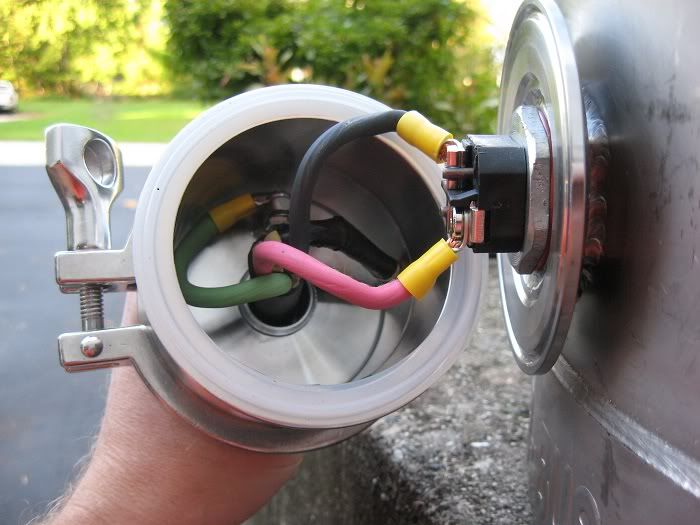

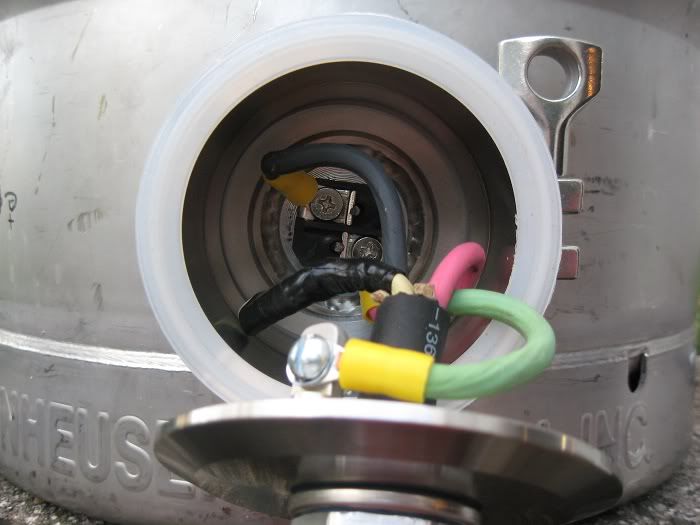

Just finished my element covers/boxes. 2" TC X 1" NPS element plate from Hillbilly Stills soldered through 14ga stainless plate which in turn is bolted to water-tight box. Provides grounding point and covers element wiring inside the box. Cable strain relief on the side for my 10/3 cords and that's it.

Have to say, even it's going slow, the build is really fun.

Thanks to many from the forum for continuing inspiration.

Have to say, even it's going slow, the build is really fun.

Thanks to many from the forum for continuing inspiration.

kpr121

Well-Known Member

Electrical tape provides no insulation value, its only there to keep the ground wire as close to the power leads as possible so it doesnt get snagged on anything. The tape also matches the aesthetics of the rest of my brewhouse, which some would describe as "Ghetto-Fabolous"

Just finished my element covers/boxes. 2" TC X 1" NPS element plate from Hillbilly Stills soldered through 14ga stainless plate which in turn is bolted to water-tight box. Provides grounding point and covers element wiring inside the box. Cable strain relief on the side for my 10/3 cords and that's it.

Have to say, even it's going slow, the build is really fun.

Thanks to many from the forum for continuing inspiration.

Kevin,

can you please post some more information regarding your build? How are you attaching the TC to the pot/keggle, and how are you securing the heating element inside the TC?

Here's how I did mine. There are a few more pictures here:

https://www.homebrewtalk.com/f170/keg-ekeggle-conversion-pics-259848/index3.html#post3408018

https://www.homebrewtalk.com/f170/keg-ekeggle-conversion-pics-259848/index3.html#post3408018

I had a 2" triclamp ferrule welded to my Blichmann boil kettle and the 2" triclamp fitting in my box/cover is threaded for 1" NPS so element screws right into it and the whole thing is clamped to kettle.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)