Boerderij_Kabouter

Well-Known Member

I can't believe this thread doesn't exist. Let's put together a resource for people to see how they want to protect themselves for electrocution!

I'll go first...

My BK uses a rubber coated keg, so my situation may be a bit different.

It is a cannibalized plastic box with an all weather face plate. The recessed outlet is sealed up with silicone and the box is fully plastic welded (plastic specific epoxy) to the keg exterior.

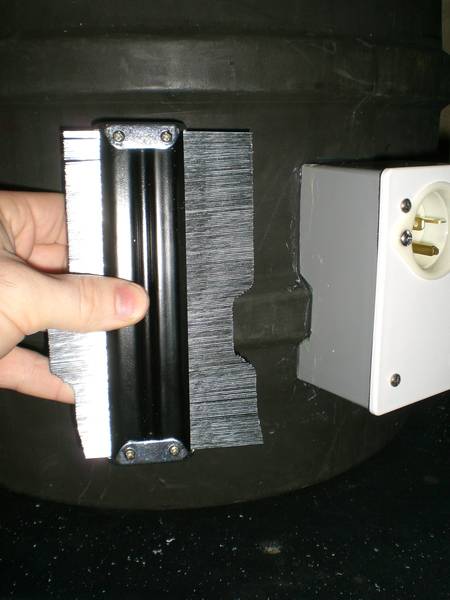

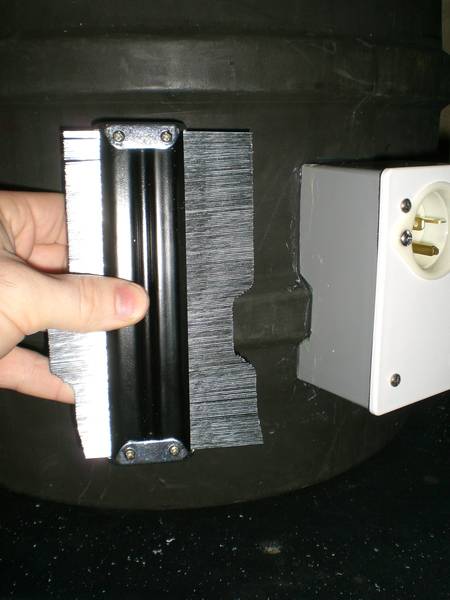

I used a profile guage to steal the profile of the keg:

Then, I traced that profile onto the box, and cut it out with my mini band saw.

Then I clamped the box in place with a bungie cord, and epoxied the crap out of it. Wiped smooth with a squeegee and bob's yer uncle.

The flash picks up some extra epoxy, but it looks perfect with the naked eye.

I'll go first...

My BK uses a rubber coated keg, so my situation may be a bit different.

It is a cannibalized plastic box with an all weather face plate. The recessed outlet is sealed up with silicone and the box is fully plastic welded (plastic specific epoxy) to the keg exterior.

I used a profile guage to steal the profile of the keg:

Then, I traced that profile onto the box, and cut it out with my mini band saw.

Then I clamped the box in place with a bungie cord, and epoxied the crap out of it. Wiped smooth with a squeegee and bob's yer uncle.

The flash picks up some extra epoxy, but it looks perfect with the naked eye.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)