I just got into the home brewing recently... but im nuts about trying to improve the process...

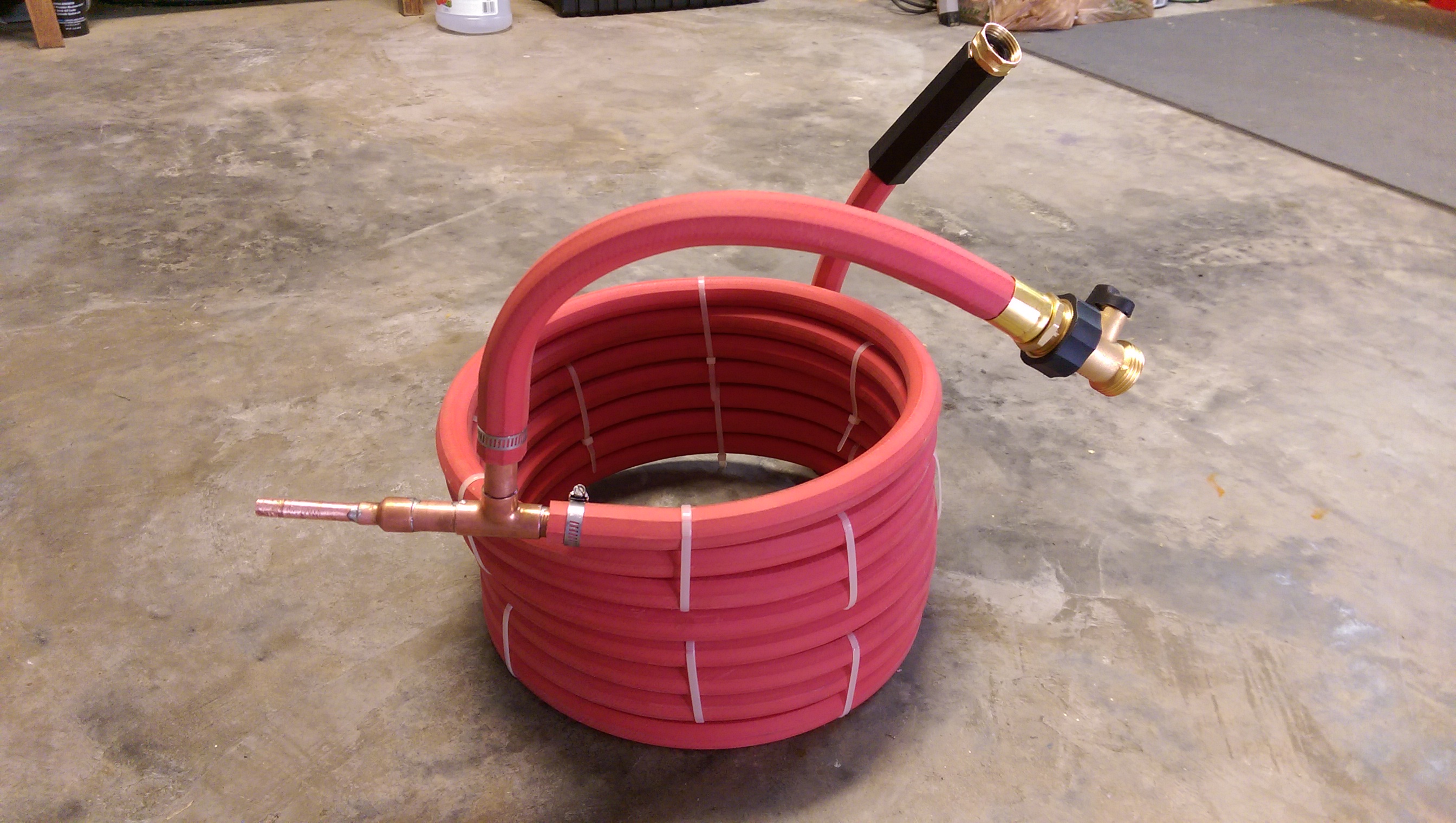

Here is the wort chiller i just built, as you can tell im neither a plumber or an engineer...

its 5 x 10ft of 1/4" copper tubing connecting to 3/8" pipe as feed and collector...

with tap water at about 68F it took about 7 minutes to hit 77F with a half batch boil.

next batch i did with it was the next size pot i was able to get my hands on without spending money... which turned out to be a 60 quart pot... so i did a double batch boil. chiller still did a fantastic job... cooled the wort in about 15 minutes with a lot of stirring and an awkward fit on a much larger pot.

i left some space on top of the 3/8" pipes and im thinking of adding another coild or two of 1/4" to allow for more surface area and water flow.

actually planning on doing a kind of step by step with all the ideas and mistakes as a guide or inspiration source for someone who can do it better... or even possibly to save someone the trouble and just do a single coil.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)