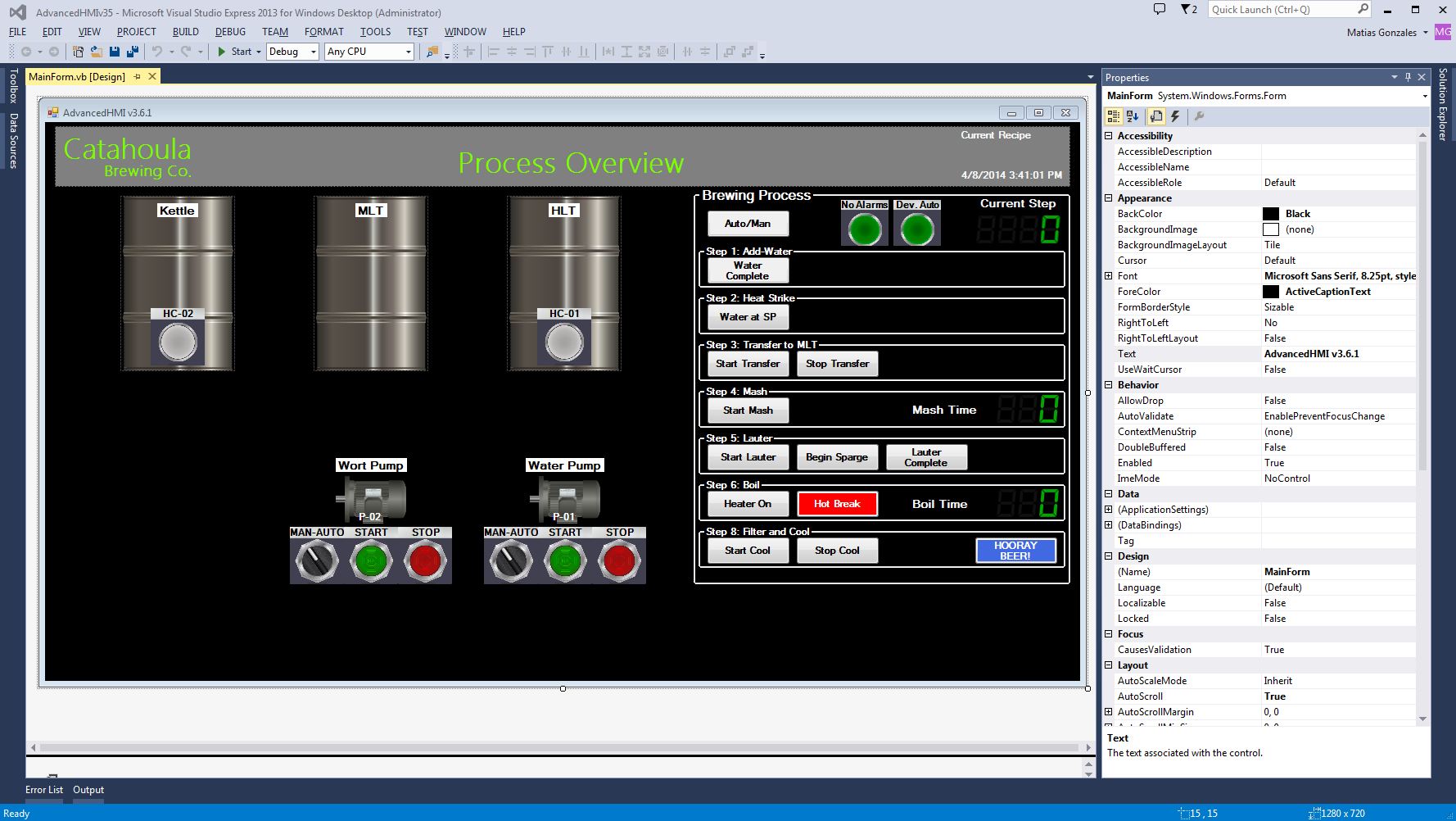

I'm curious if anyone is willing to share their ladder logic for their automated brew systems. I've started getting my stuff to make a PLC brewery. I've got a AB SLC500 Fixed Hardware 1747-L30C, expansion chassis and two 4 point analog input modules. I also have RSLinx/RsLogix 500 and AdvancedHMI and have gotten it all to communicate. I'm an instrument & automation tech by trade but I'm really just learning PLC programming so I'm wondering if anyone has any logic they've done I can study and perhaps adapt to my project. Doesn't have to be allen-bradley, I'd love to see anyone's logic. Thanks in advance.

BTW, if anyone wants to embark on a similar project I have two more 1747-L30Cs I'll sell for like $40 each + shipping to HBT members, just PM me.

BTW, if anyone wants to embark on a similar project I have two more 1747-L30Cs I'll sell for like $40 each + shipping to HBT members, just PM me.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)