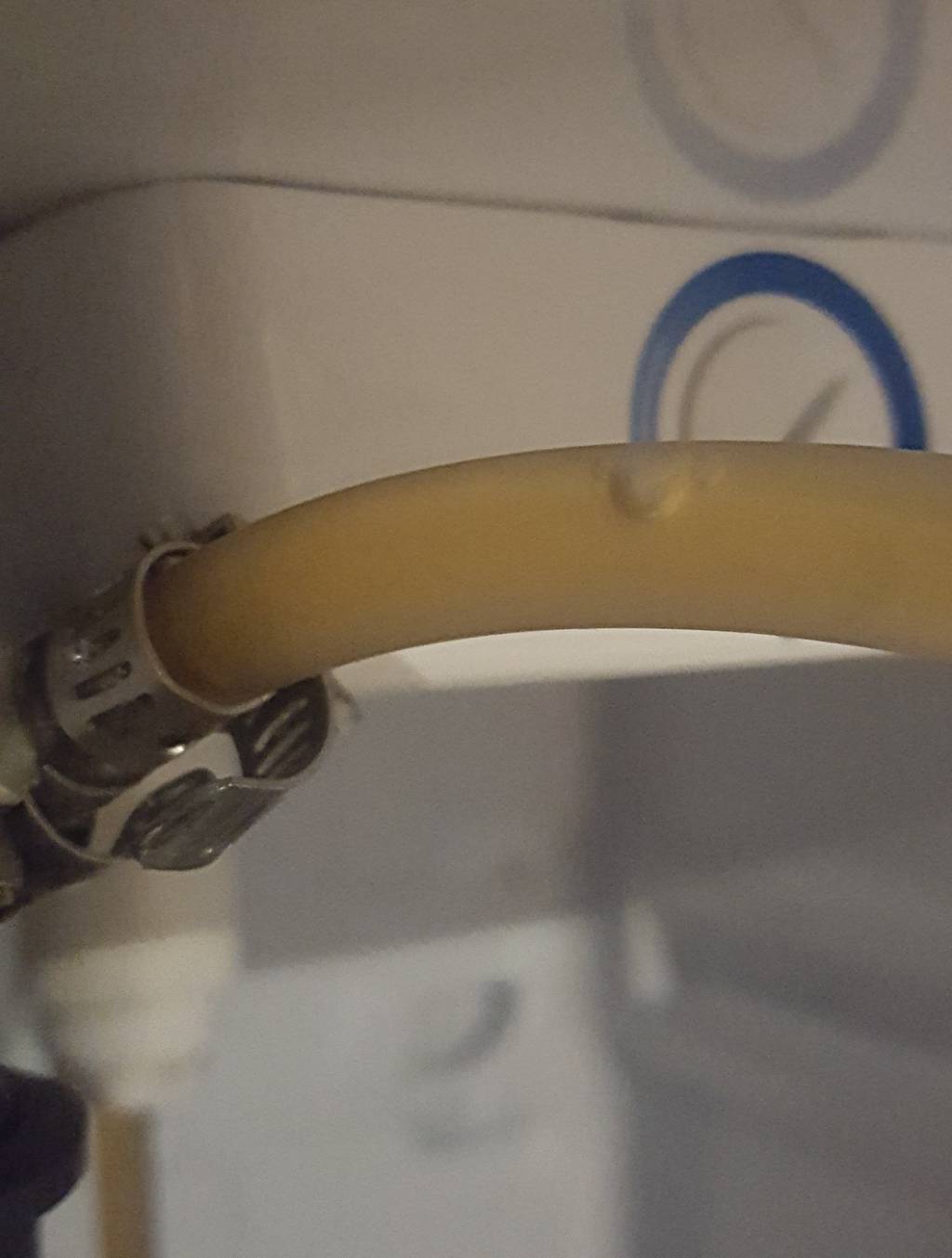

I do home brew but recently I've been buying commercial kegs, I have 10ft 3/8OD 1/4ID vinyl tubing, reg set to 14psi, older perlick sanke coupler with ball lock adapters, into a intertap flow control....since doing commercial i get full glasses of dense Foam, microbubbles in the line and then it turns to foam at the tap, I've cleaned and sanitized, take things apart to check for kinks and such. The only thing I don't have yet is a tower cooler but I'm in the process of building one so, I'm at a loss of words and ideas on how to fix the problem. When pouring and restricting the flow it's like hissing or (turblating). It's a brand new g2 fc