quaboagbrewing

Well-Known Member

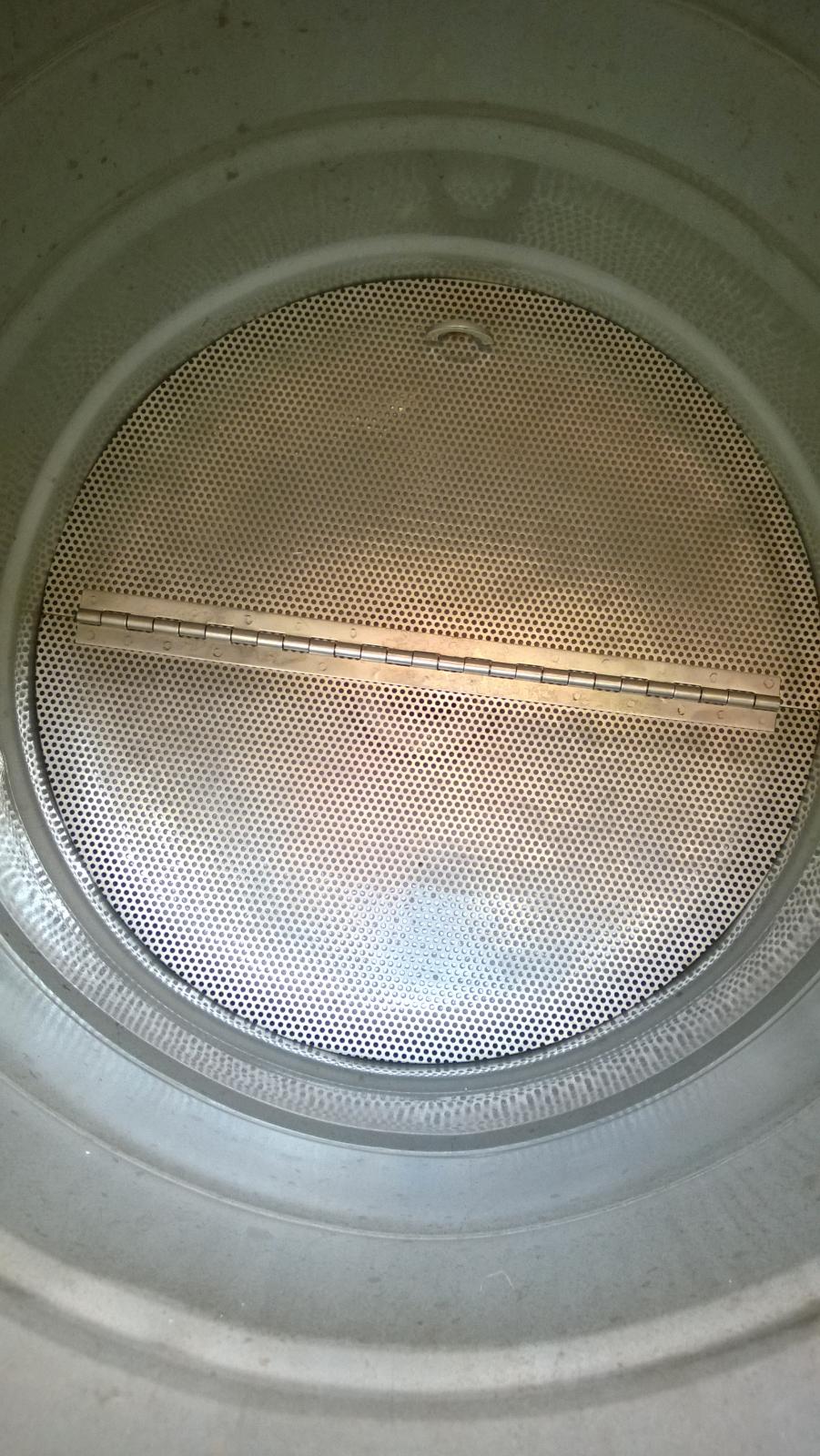

A local brewery was kind enough to set aside a few retired sanke kegs for me to convert to keggles. The kegs appear from the photo they provided to be like corney kegs with rubber handles on top and rubber on the bottom as well. Can I remove the rubber from these (or if I am going to be adding electric elements to them do I even need to). I have attached a picture of one of the kegs

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)