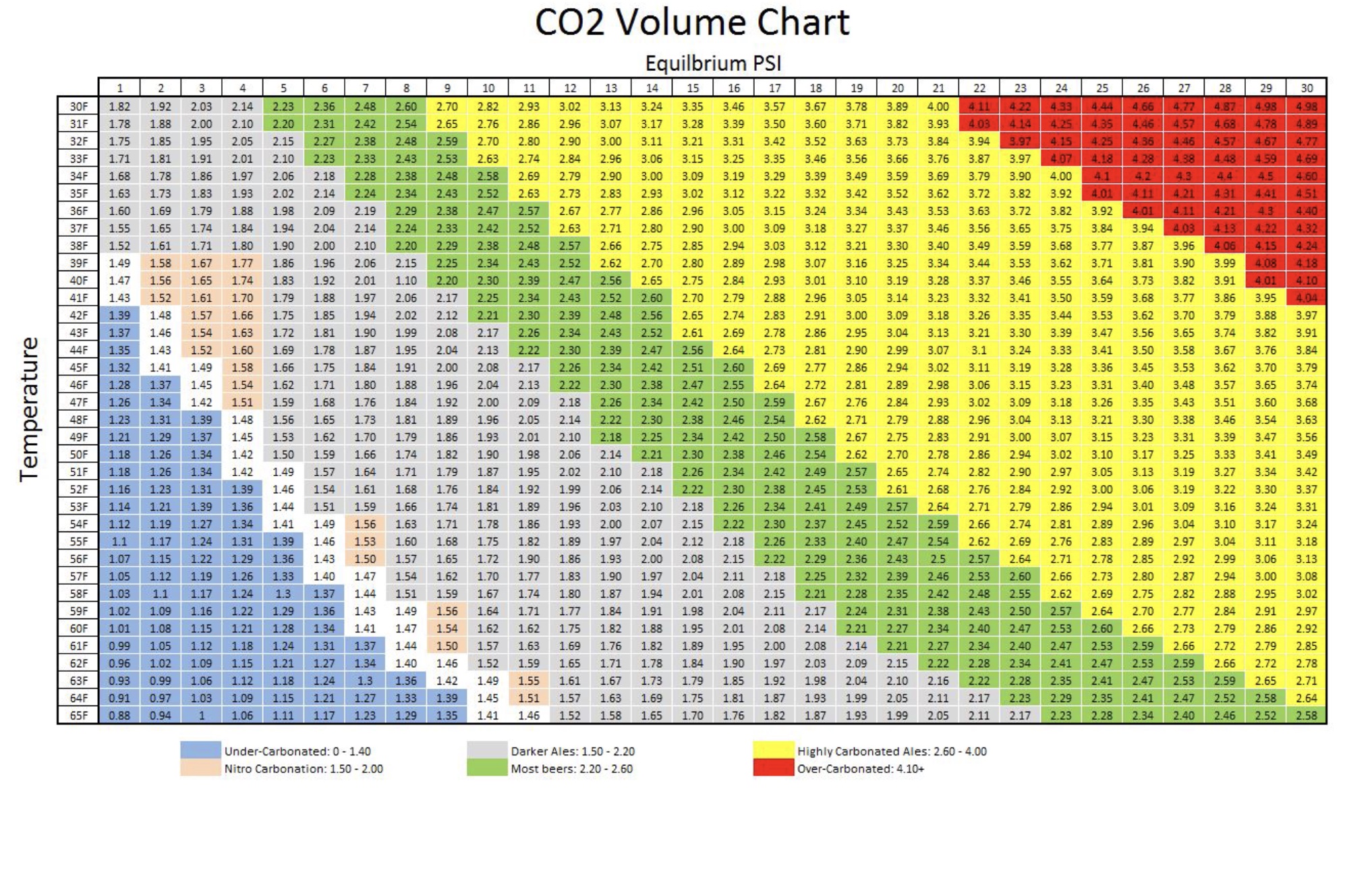

Hi. New to keg systems. Have 2x 8L kegs. Sits in a fridge at around 6°c (43°f). Vertical distance from centre keg to tap is 870mm (2.854’). CO2 set to 9psi (have tried 12). Using 4mm (0.15748”) ID beer hose. Have 1.2m (3.937’) in the fridge, and then about 600mm (1.9685’) outside to the taps (wrapped in insulation). 1.8m (5.9055’) total.

Did the calcs on mikesolty, and got 1.14m (3.75’) required. Thought perhaps the too long a line caused a pressure drop causing froth. Trimmed the line back to the 3.75’. No change. Probably a little worse. Once froth settles, beer tastes flat.

I’m out of ideas.

Did the calcs on mikesolty, and got 1.14m (3.75’) required. Thought perhaps the too long a line caused a pressure drop causing froth. Trimmed the line back to the 3.75’. No change. Probably a little worse. Once froth settles, beer tastes flat.

I’m out of ideas.