deadwolfbones

Well-Known Member

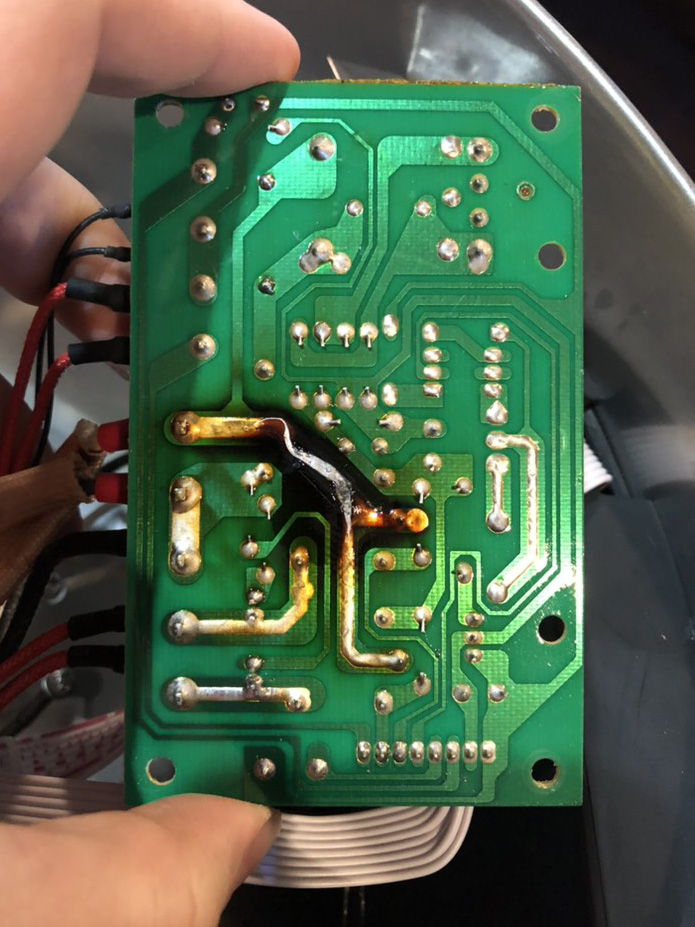

Taking the high load off a circuit board is a common mod for cheap 3d printers. Their heated print beds are high amp for the cheap printed boards they typically come with.

It looks like there's enough space there in the base of the robobrew the fit an SSR and heatsink... You could use that power connection as an SSR signal instead. Install an SSR and remove a ton of the load from the printed board to up it's life. Would probably be a $20 mod if you have the wire handy.

Have to admit this is like sanskrit to me. Googling tells me a SSR is a solid state relay, but I have no idea how to go about wiring such a thing.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)