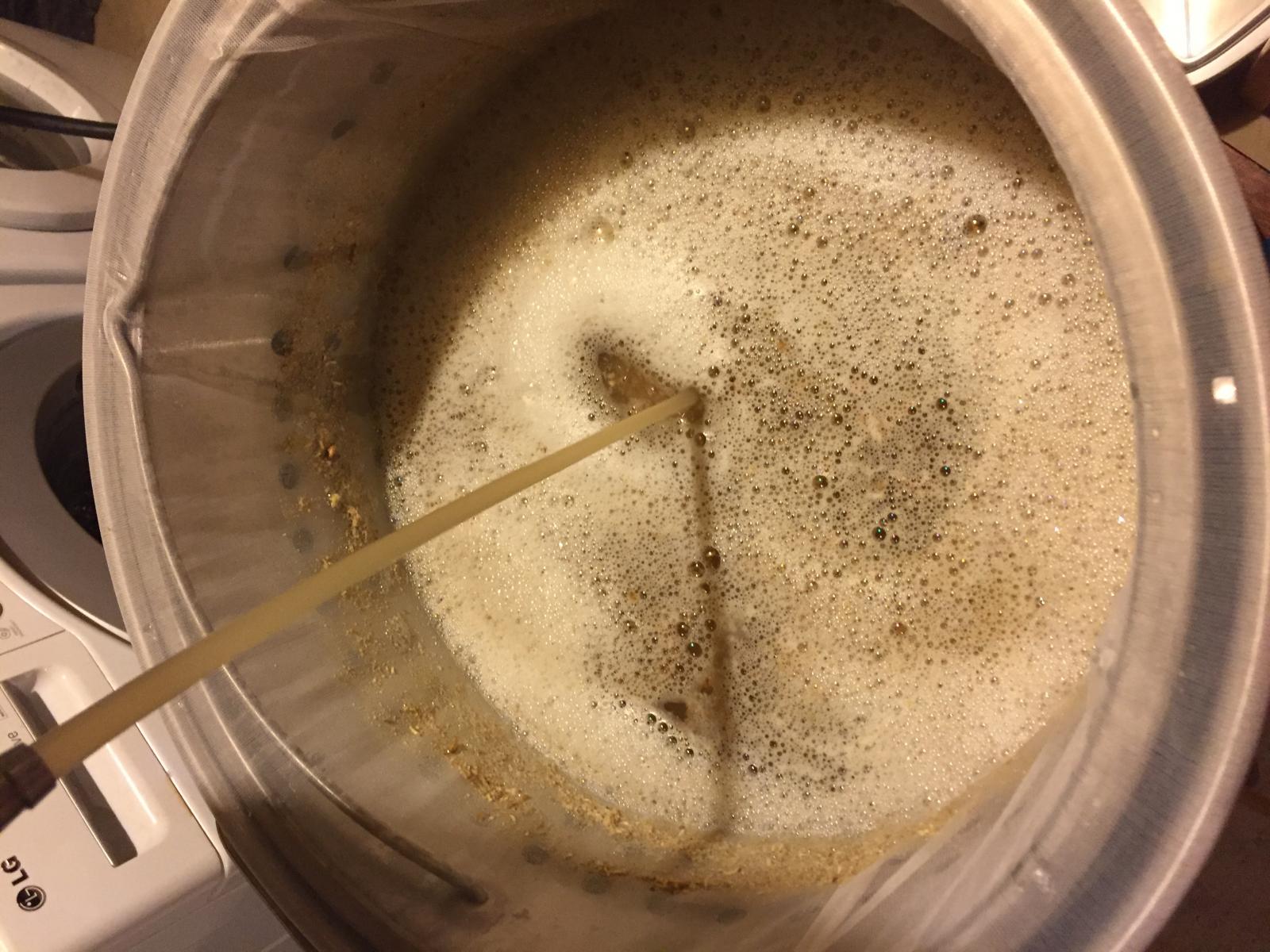

I'm working on an eBIAB build using a 15G Bayou Classic kettle (1160) with a BoilCoil and recirculation pump. I've been planning to have two return ports, one in the lid for recirculation during mash, and one for whirlpooling using the SpinCycle from Brew Hardware. But as I was about to start drilling last night, a couple questions came up:

-Will the steamer basket still fit properly with the SpinCycle installed under the ridge of the kettle? It seems like the basket will fit, but will be sort of pushed over to one side. I need to raise the basket slightly with SS bolts anyway, to give the BoilCoil room underneath. Has anyone used this exact setup with a SpinCycle? I'm worried about the basket not going in and out smoothly, or resting awkwardly in the kettle.

-Would it make more sense to build a whirlpool arm that hangs over the side of the pot? That way, I could use it for both mash recirculation (by putting it inside the basket/bag) AND for whirlpooling after the boil. It seems like this would help keep the grain bed fluid and mash temps stable. I could do this using the SpinCycle that I already have, and adding an elbow to help it hang on the rim of the pot. I'd have to cut a notch in the lid or leave it partially open. My biggest concern here would be the mesh bag getting all twisted up. Has anyone done anything like this?

Thanks for any input! It's pretty nerve-racking to finally start drilling after all this planning.

-Will the steamer basket still fit properly with the SpinCycle installed under the ridge of the kettle? It seems like the basket will fit, but will be sort of pushed over to one side. I need to raise the basket slightly with SS bolts anyway, to give the BoilCoil room underneath. Has anyone used this exact setup with a SpinCycle? I'm worried about the basket not going in and out smoothly, or resting awkwardly in the kettle.

-Would it make more sense to build a whirlpool arm that hangs over the side of the pot? That way, I could use it for both mash recirculation (by putting it inside the basket/bag) AND for whirlpooling after the boil. It seems like this would help keep the grain bed fluid and mash temps stable. I could do this using the SpinCycle that I already have, and adding an elbow to help it hang on the rim of the pot. I'd have to cut a notch in the lid or leave it partially open. My biggest concern here would be the mesh bag getting all twisted up. Has anyone done anything like this?

Thanks for any input! It's pretty nerve-racking to finally start drilling after all this planning.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)