r8rphan

Well-Known Member

Is a separate 'rinse' always required?

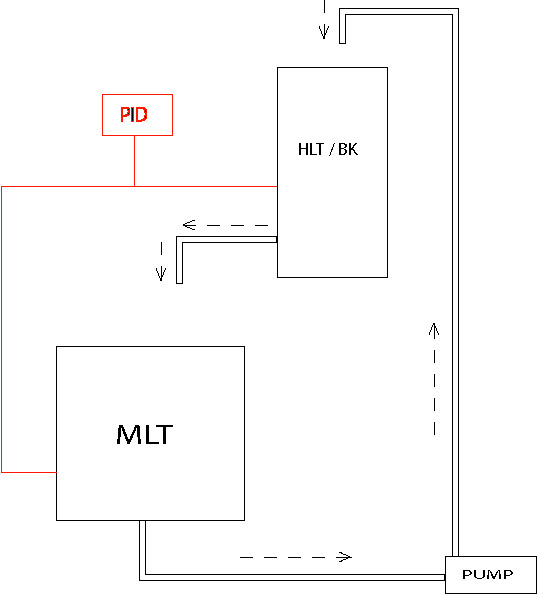

The reason I'm asking, is I was wondering about RIMS systems and why the boil kettle can't be used as part of the setup..

I'm wondering why you can't just recirculate the desired pre boil volume of water (plus that which is to be absorbed by the grain) through the mash for an hour, then raise the temp for an additional 15 minutes afterwards...

IOW, if you have 12-13G you need for the boil in your boil keggle, heat it, infuse it into the mash tun, recirculate it through the boil keggle and back into the mash tun, adding the make up for grain absorbtion, then let it continue to circulate for an hour at mash temp, finally raising it to the sparge temp for 15 mins or whatever, and then just pumping all the wort from the mash tun into the boil keggle.. isn't that the same thing?

Or must you do a rinse with clean heated water? If so, why?

The reason I'm asking, is I was wondering about RIMS systems and why the boil kettle can't be used as part of the setup..

I'm wondering why you can't just recirculate the desired pre boil volume of water (plus that which is to be absorbed by the grain) through the mash for an hour, then raise the temp for an additional 15 minutes afterwards...

IOW, if you have 12-13G you need for the boil in your boil keggle, heat it, infuse it into the mash tun, recirculate it through the boil keggle and back into the mash tun, adding the make up for grain absorbtion, then let it continue to circulate for an hour at mash temp, finally raising it to the sparge temp for 15 mins or whatever, and then just pumping all the wort from the mash tun into the boil keggle.. isn't that the same thing?

Or must you do a rinse with clean heated water? If so, why?