BadNewsBrewery

Well-Known Member

Details on that fridge? Very nice.

- they can't be under-the-counter, and you have to have clearance above them to open them.

2. do you have need to heat these? If so, how to you accomplish this?

Keith

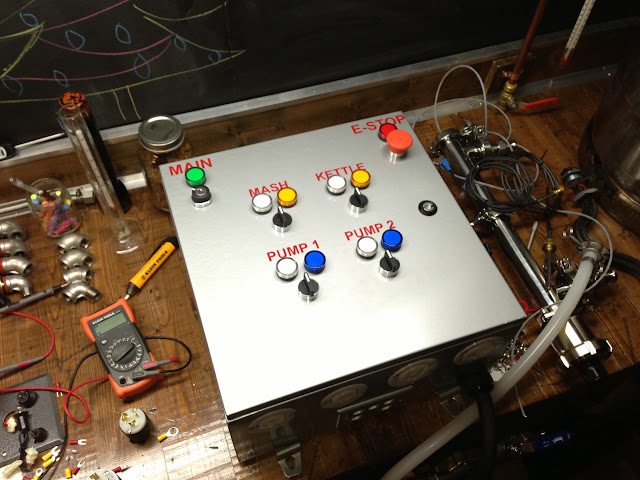

Why 2 lights per control?

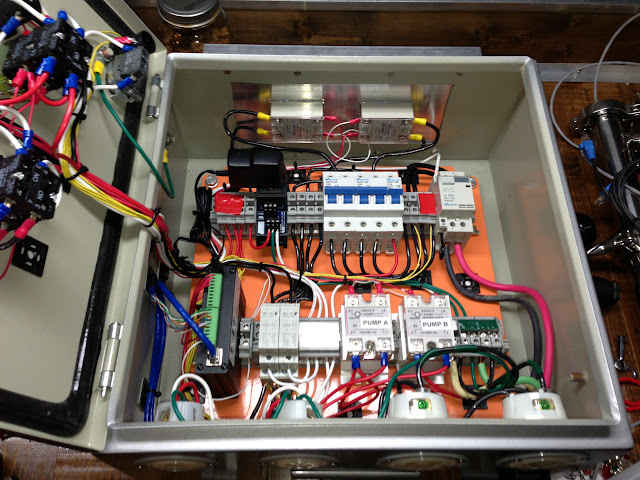

With your breakers - the double pole ones show two black wires coming out. Did you give up on standard wire convention (one red, one black), or is there a reason you are using a double pole breaker with only one hot leg split between both sides?

Otherwise, very clean panel. I couldn't bundle all my wires as nicely, that's for sure!

Are you an actual garbage man?

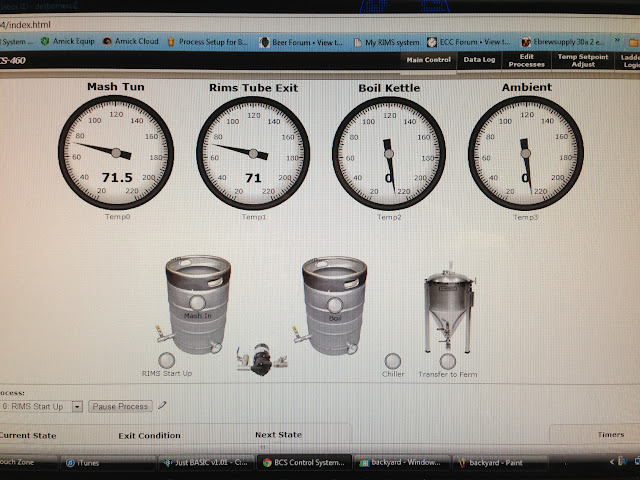

garbageman said:I control RIMS element by probe at end of RIMS tube. Add 7 degrees to set point to equalize temp in Mash Tun. IE: RIMS exit temp 158 = 151 in grain bed.