The LODO guys have a video of fermentation pushing out sanitizer and filling a keg with CO2.

Vitality Starter

author S. cerevisiae

All one needs to make a well-shaken starter is a sanitizable vessel that is at least four times the volume of the starter being prepared, a sanitizable screw-on cap for the vessel, and a funnel. I do not know if anything comparable is available in the UK; however, one U.S.-gallon glass jugs (demijohns in UK speak) are plentiful in the United States. Home brew supply stores sell plastic replacement caps for these jugs that can be sanitized (38mm polyseal screw top caps). If one has money to burn, a 5L borosilicate glass media bottle like I currently use is a very nice toy. However, 5L media bottles can cost prohibitive when purchased new. I acquired my current 5L media bottle as unused laboratory surplus, and it was not cheap. I used a 1-gallon glass jug for a very long time before switching over to using a 5L media bottle.

Preparing the starter medium (a.k.a. starter wort)

The starter medium is prepared like one would prepare a starter any other way. A 10% weight/volume solution is made by mixing 100 grams of pale DME into a little more than 1L of water. The goal here is to end up with 1L of media after the solution has been boiled and cooled to room temperature. I boil the solution for 15 minutes in a 3-quart stainless steel sauce pan (A U.S. quart is slightly smaller than a liter). The media is chilled in the sauce pan with the cover affixed using an ice water bath in my kitchen sink.

Sanitizing the starter vessel, screw-on cap, and funnel

The starter vessel, screw-on cap, and funnel should be sanitized while the medium is boiling and chilling. While I use bleach and StarSan, feel free to use your preferred sanitizer. It is critical that the funnel is sanitized as well, and that one does not touch the inside surface of the funnel after it has been sanitized.

Note: One thing that I like to teach home brewers is to get into the habit of wiping the lip over which yeast or nutrient will be poured with an alcohol saturated cotton ball before decanting yeast, medium, or supernatant (supernatant is the clear liquid that lies above the solids in a starter, yeast crop, or a batch of beer). Wild microflora (yeast, mold, and bacteria) rides through the air on house dust. What we want to do is ensure that we do not drag any dust that may have come to rest on the pouring lip of the container that we are decanting into a vessel in which we intend to grow a culture or ferment a batch of beer. This precaution makes sense If one thinks about what a nurse or doctor does before giving one an injection. The reason why a doctor or a nurse cleans an injection site with an alcohol wipe before giving one an injection is to prevent the needle from dragging microflora that is on one’s skin into the injection site.

Pouring the starter medium

After placing the funnel in the starter vessel, one should wipe the pouring lip of the sauce pan in with an alcohol saturated cotton ball before pouring the starter medium into the starter vessel. I use 70% or 90% isopropyl alcohol. I used to use 95% ethanol (a.k.a. grain alcohol). However, my state outlawed its sale due to teenagers and young adults abusing it. Any 140 proof or better clear spirit will work. Please do not use methylated spirits.

Inoculating the starter medium

If using a White Labs vial, wipe the pouring lip of the vial with an alcohol saturated cotton ball before pouring the yeast culture into the starter vessel. If using a Wyeast smack pack, wipe the outside of the smack and the blades of the pair of scissors that one is using to cut a corner off of the smack pack with an alcohol saturated cotton ball before making the cut, and wipe the cut edge of the smack pack with an alcohol saturated cotton ball before pouring the contents of the smack pack into the starter vessel.

Caping and shaking

Here’s where my method differs from the way the average home brewer makes a starter. The reason why a vessel with a screw-on cap is necessary with this method is because one is going to shake the culture very vigorously for about a minute. I usually tell brewers to shake the starter vessel like it owes you money (think mafia enforcer). The goal here is to attempt to turn the media into foam. That's why the vessel has to be at least four times the volume of the starter. One should then allow the starter to sit for around thirty minutes before loosening the cap to allow the foam to drop.

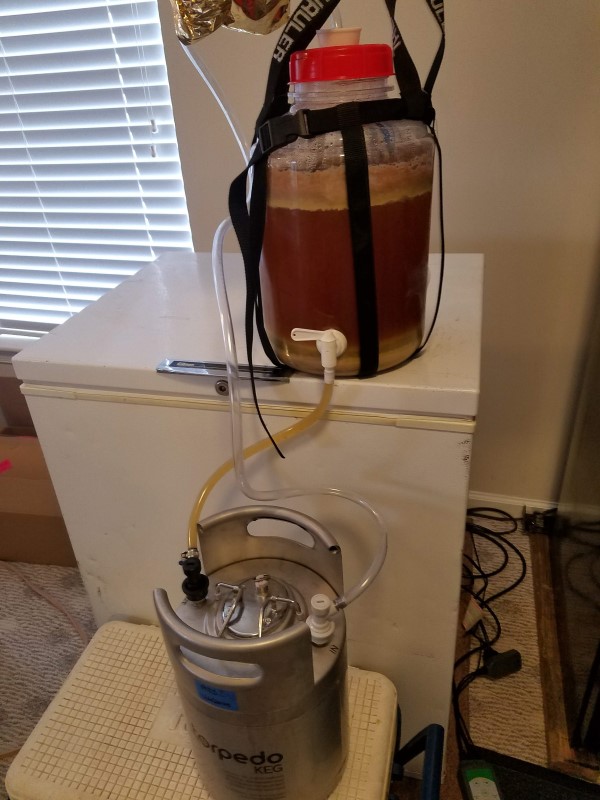

A well-shaken starter in a 5L media bottle

[/URL]

Pitching the starter

Pitching is one area where most home brewers get it completely wrong. A starter is not a small batch of beer. It is a yeast biomass growth medium. The goal here is to grow the culture to maximum cell density and then pitch it. Maximum cell density occurs at high krausen. Beyond that point, all cell reproduction is for replacement only. Yeast taken at high krausen is much healthier than yeast that is taken from a sedimented starter or batch of beer. That’s why traditional breweries crop yeast at high krausen. Allowing a starter to ferment out and settle places the cells in the yeast equivalent of hibernation where they will have to undo survival-related morphological changes that occurred at the end of fermentation as well as completely replenish their ergosterol and unsaturated fatty acid reserves after being pitched.

High krausen should occur within 12 to 18 hours after pitching the starter. The yeast biomass grows exponentially, not linearly. The yeast cell count grows at a rate of 2^n, where the symbol “^” means raised to the power of, and n equals the number of minutes that have elapsed since the end of the lag phase divided by 90; hence, the difference in propagation time between 200B cells and 400B cells can be as little as 90 minutes.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)