BFD_BrewGeek

Well-Known Member

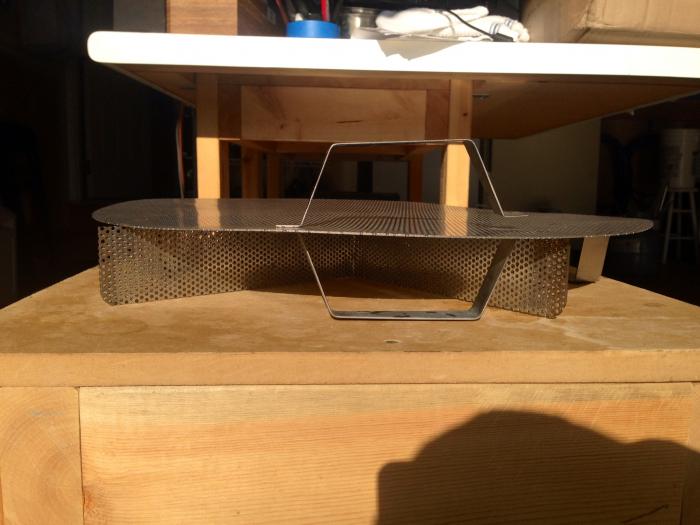

I was in the habit of running a recirculation mash with the pump valves wide open. I always thought if the mash stuck, you can just stop the pump, stir the mash, and continue on with the recirculation...right?...until my false bottom collapsed (see pic) and I had to totally empty the mash into another vessel and jury rig the false bottom, just to get through the brew day. This happened on 3 batches, generally when the malt bill exceeded 30 lbs, all barley malt. (15 gallon mashtun, 11 gallon batches, as close to 1.5 quarts/lb strike water as I can get). 0.039 mill gap.

So what is happening? Pump suction due to grain bed compaction? Weight of grain and water exerting force on the legs of the false bottom? Combination of the two? Any ideas?

Possible solutions that I've considered:

1. Reduce recirculation flow, valve half open. This reduces temperature response of the system, but it beats the schmitt out of emptying my mashtun and hammering my false bottom back in shape.

2. Reinforce/add supports for the false bottom. Any ideas?

3. Increase the gap on my mill to get a more course crush...0.045? My mash efficiency isn't really all that great to begin with (~0.80), but willing to try it to avoid another FB collapse.

4. Add rice hulls to the grain bill...hate that idea...no one else I know does that unless the grain bill is 50% or higher in wheat or rye, or god forbid...pumpkin...

5. Limit my grain bill to less than 30 lbs of grain. Reduce batch size to maintain SG.

6. Add a suction gauge to the outlet of the mash tun so I know when a vaccum is forming, stirring mash if required.

Other ideas?

Anyone with a similar experience?

What worked for you?

Any help is really appreciated...

So what is happening? Pump suction due to grain bed compaction? Weight of grain and water exerting force on the legs of the false bottom? Combination of the two? Any ideas?

Possible solutions that I've considered:

1. Reduce recirculation flow, valve half open. This reduces temperature response of the system, but it beats the schmitt out of emptying my mashtun and hammering my false bottom back in shape.

2. Reinforce/add supports for the false bottom. Any ideas?

3. Increase the gap on my mill to get a more course crush...0.045? My mash efficiency isn't really all that great to begin with (~0.80), but willing to try it to avoid another FB collapse.

4. Add rice hulls to the grain bill...hate that idea...no one else I know does that unless the grain bill is 50% or higher in wheat or rye, or god forbid...pumpkin...

5. Limit my grain bill to less than 30 lbs of grain. Reduce batch size to maintain SG.

6. Add a suction gauge to the outlet of the mash tun so I know when a vaccum is forming, stirring mash if required.

Other ideas?

Anyone with a similar experience?

What worked for you?

Any help is really appreciated...