No longer a theory for me. Figured out I could test this, with an empty keg, posts with the various springs under them, and a QD with a length of CO2 hose attached to it, filled with water.

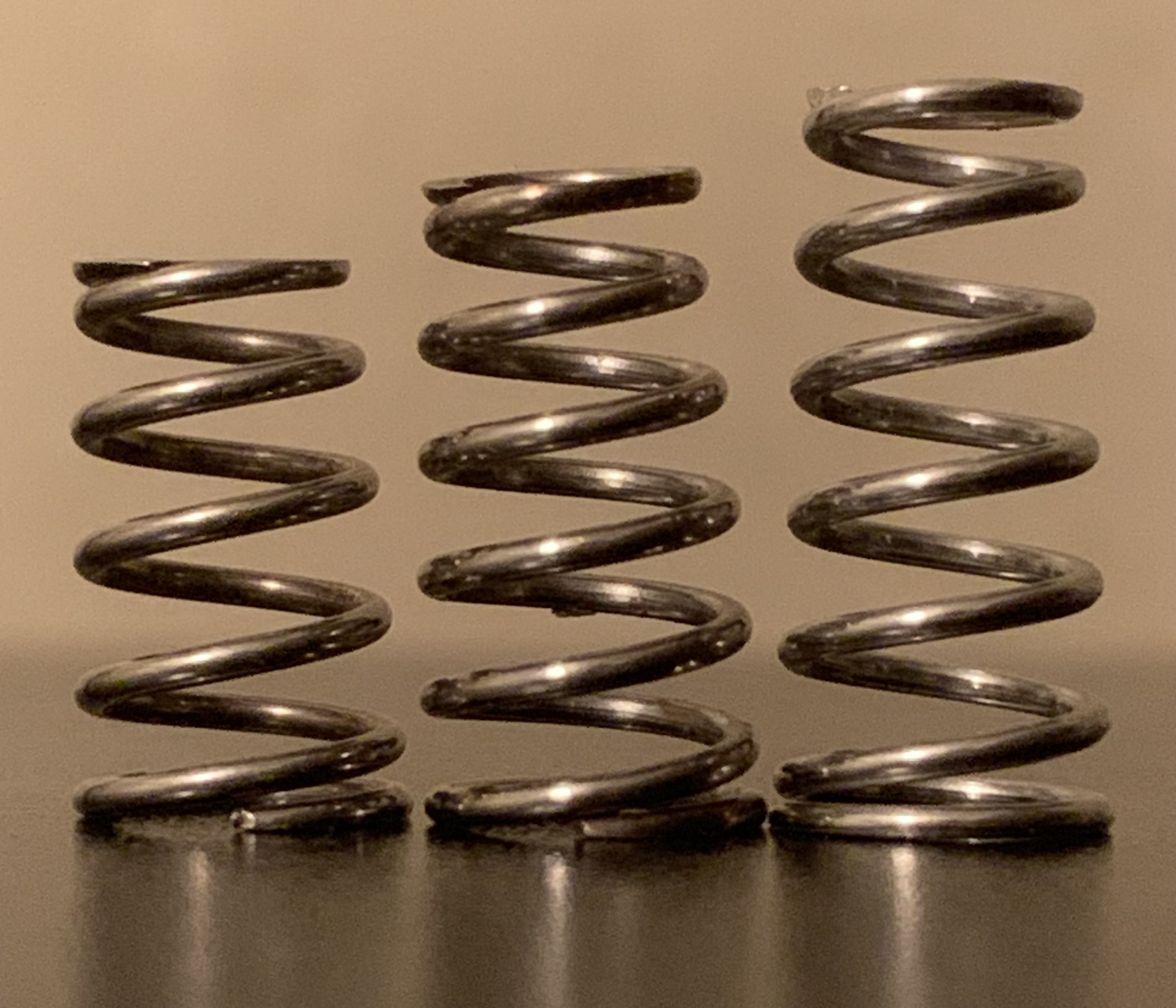

The short spring on the left allows the hose to drain into the keg at what I'd call a fast speed. The spring on the right takes this down to "drops", 2 or 3 a second. Fast drops, but nowhere near the speed of the short spring.

So, I'll try finding more short springs, I've already emailed Bobby's store and one more as a backup plan. I could probably just cut the longer ones but I'd prefer them to have a flat ground surface where they hit the bottom of the poppet.

If folks have foaming issues, you might consider this as a cause. I might have to give my "picnic tap 2.0" another shot, giving it a smoother flow to start with might help.

View attachment 855307

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)