- Joined

- Apr 16, 2020

- Messages

- 46

- Reaction score

- 27

I have been reading through the forum for a couple months now wanting to build my own 10-gallon batch EBIAB basket system which will have constant recirculation from the mash forward via a spray nozzle in the lid.. I believe I finally have all of my thoughts together and want to get everyone's feedback prior to ordering my system. Just for full disclosure, I plan to order this system by the end of the week because I realize that patience is a virtue that I lack and also because I know that it will take some time to get all of my components together since they are fully custom. Admittedly, I know that I tend to greatly over-engineer systems at times so if there is anything that is COMPLETELY unnecessary, please point that out in advance.

For the controller I am going with a 240V Grounded Brewing Technology controller but using an Auber DSPR320 Boil Control in place of the Omron PID since I want to be able to step mash with a timer as well as have a delayed start option which Rex offered as a solution. I will use a 5500 W element which should work pretty well for this application from what I have read here.

https://www.groundedbrewingtechnologies.com/products/30a-biab-control-panel

For the Boil Kettle I am ordering a 20-gallon custom kettle from Spike with all TC couplers located 2" off the bottom of the kettle to limit the amount of dead space water between the bottom of my basket and the element/pickup tubes. I want to use TC clamps so that we can clean down to the bare kettle after every brew day (realistically it will probably be every other) and I like how they function even though they are likely overkill. The configuration I am going for looks like this:

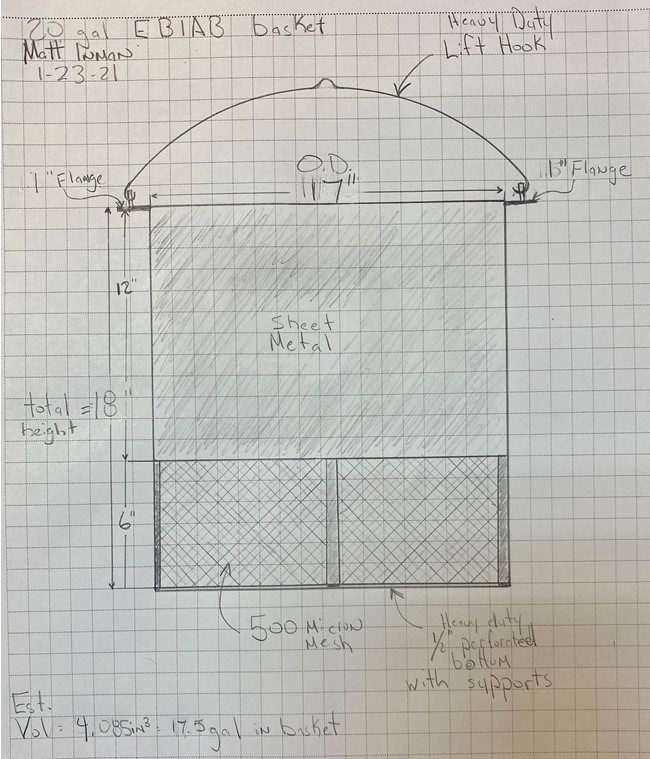

For the basket I plan to order from Utah Biodiesel Supply and it is intended to have a flange on the top which will hold the entire grain load without having feet that can hit the thermocouple and the heating element. This probably is a highly over-engineered part of my system or something that I am overthinking but I don't want to have anything that could bump those parts while we are using them and it makes more sense to me to suspend it from the top. From my math I should have approximately an inch between the heating element and the bottom of the mash basket. The metal sides are intended to prevent the recirculation water from just hitting the top of the basket and short circuiting without going through the majority of the grain bed.

Please critique my system and let me know if there are any areas that could be improved or any potential issues. Thanks in advance guys!

For the controller I am going with a 240V Grounded Brewing Technology controller but using an Auber DSPR320 Boil Control in place of the Omron PID since I want to be able to step mash with a timer as well as have a delayed start option which Rex offered as a solution. I will use a 5500 W element which should work pretty well for this application from what I have read here.

https://www.groundedbrewingtechnologies.com/products/30a-biab-control-panel

For the Boil Kettle I am ordering a 20-gallon custom kettle from Spike with all TC couplers located 2" off the bottom of the kettle to limit the amount of dead space water between the bottom of my basket and the element/pickup tubes. I want to use TC clamps so that we can clean down to the bare kettle after every brew day (realistically it will probably be every other) and I like how they function even though they are likely overkill. The configuration I am going for looks like this:

For the basket I plan to order from Utah Biodiesel Supply and it is intended to have a flange on the top which will hold the entire grain load without having feet that can hit the thermocouple and the heating element. This probably is a highly over-engineered part of my system or something that I am overthinking but I don't want to have anything that could bump those parts while we are using them and it makes more sense to me to suspend it from the top. From my math I should have approximately an inch between the heating element and the bottom of the mash basket. The metal sides are intended to prevent the recirculation water from just hitting the top of the basket and short circuiting without going through the majority of the grain bed.

Please critique my system and let me know if there are any areas that could be improved or any potential issues. Thanks in advance guys!

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)